Precision inertial measurement units based on fiber optic gyroscopes are designed for extreme accuracy, but they are also sensitive instruments. Users often discover that after long periods of inactivity, startup takes longer, bias stability worsens, and output drifts beyond expectations. The simplest way to avoid these issues is regular power-on cycles, which keep the system stable, healthy, and mission-ready.

Powering on a fiber optic IMU regularly stabilizes its thermal environment, refreshes bias calibration, and prevents long-term degradation of electronic components—ensuring fast startup and dependable performance.

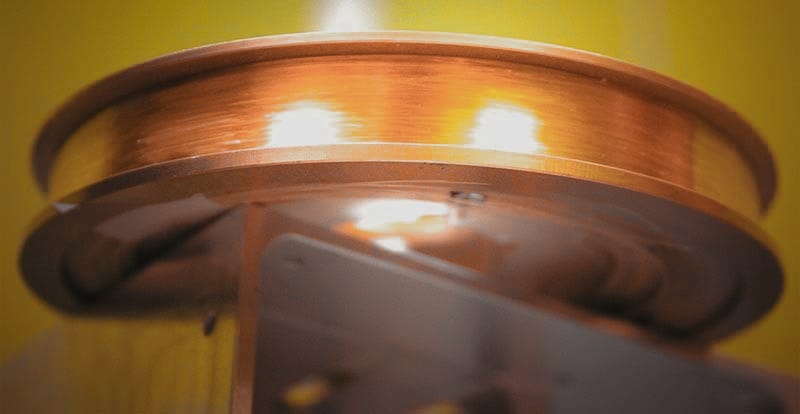

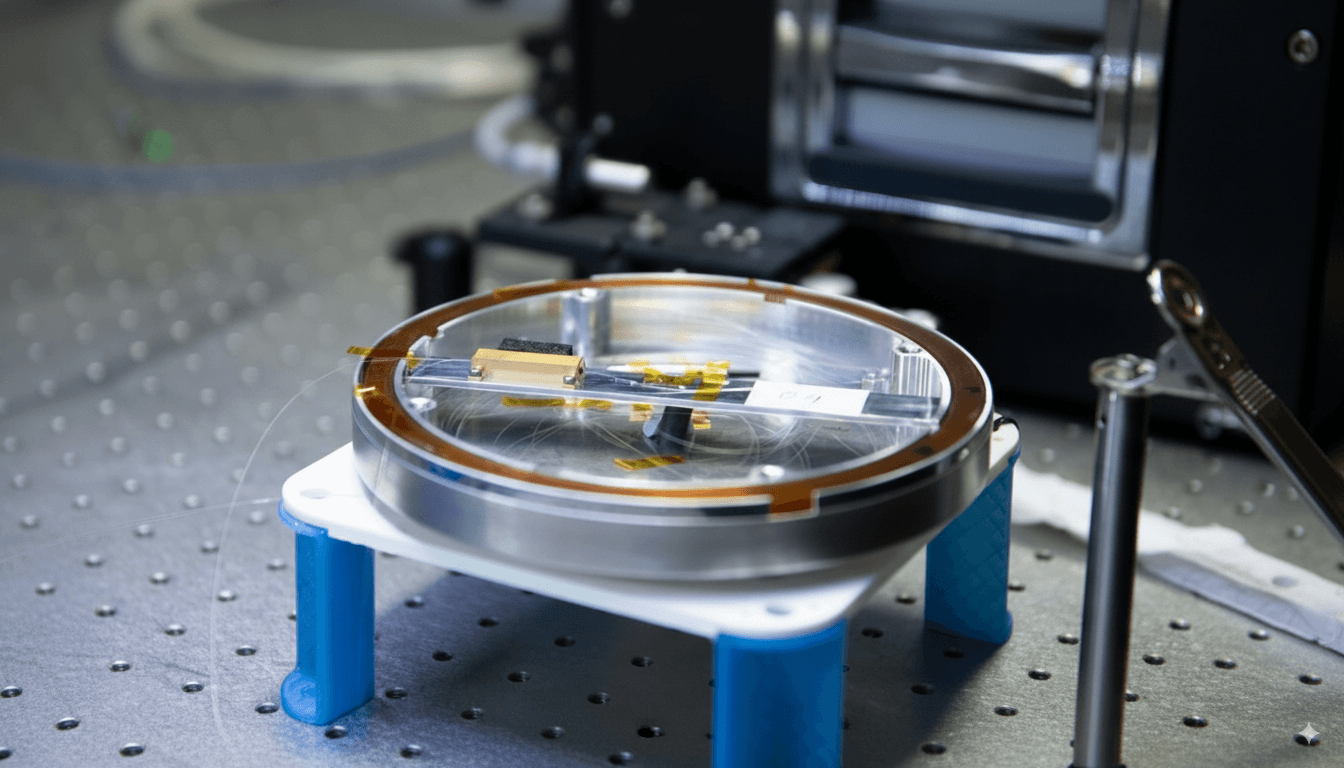

A fiber optic IMU is not like an ordinary consumer sensor. It houses laser sources, fiber coils, detectors, and precision electronics that must remain in a well-conditioned state to deliver the accuracy promised on the datasheet. Regular power-on sessions are more than a maintenance tip—they are a critical requirement to sustain performance over the product’s lifetime.

Table of contents

Why Is Thermal Stability So Critical for a Fiber Optic IMU?

The accuracy of a fiber optic gyroscope depends heavily on its thermal state. When starting cold, bias and scale factor errors can be up to ten times larger than in steady operation. Components such as laser sources and fiber coils are especially temperature-sensitive, and their combined errors delay convergence. Regular powering ensures the IMU frequently reaches its optimal temperature window, reducing cold-start drift and ensuring the sensor is close to its designed precision whenever a mission begins.

How Does Regular Power-On Refresh Bias and Internal Health?

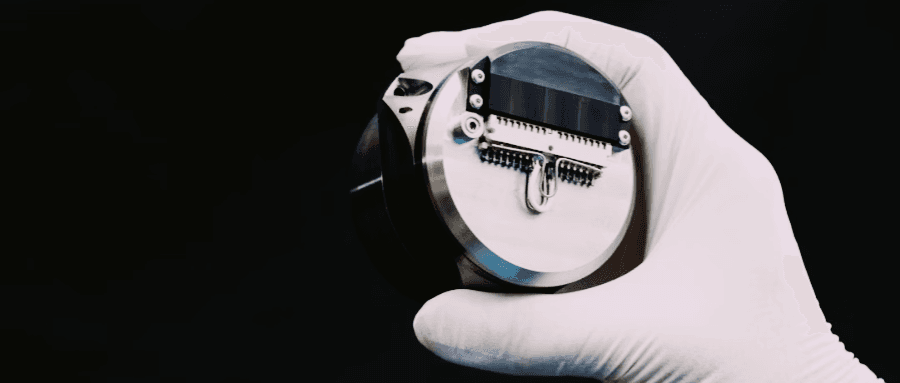

Every power-on cycle triggers built-in self-tests (BIT). These routines monitor laser intensity, detector health, and signal strength, while the algorithms re-estimate bias levels and update compensation tables. Without regular activation, bias models drift, leading to longer calibration times and sometimes false alarms at the next startup. Routine powering keeps bias models current, so the IMU aligns smoothly and reliably each time it is used.

What Are the Risks of Leaving a Fiber Optic IMU Unused for Too Long?

A fiber optic IMU is not designed to sit on the shelf indefinitely. When the device remains inactive for months, the delicate balance of its optical and electronic subsystems begins to deteriorate in ways that are not immediately visible. Long-term idleness gradually erodes component health, slows down stabilization, and increases the risk of failure right when the unit is needed most.

- Electrolytic capacitors degrade without charge– if not periodically energized, they lose dielectric strength, causing higher leakage current or even startup failure.

- Moisture and thermal cycling impact bias stability– stored in humid or fluctuating environments, the IMU may show larger drift and longer stabilization times at the next use.

- Cold-start stress on electronics– sudden powering after long idle periods can put excess strain on laser sources and analog circuits, accelerating wear.

- Hidden reliability risks– these issues may stay unnoticed until the IMU is urgently required, leading to unexpected downtime or mission delays.

How Should a Fiber Optic IMU Be Maintained Through Regular Power-On?

Even though every application has unique conditions, experience shows that a disciplined power-on routine is the most effective way to preserve accuracy and reliability. The table below highlights the difference between good practice and the risks of leaving the IMU idle for too long:

| Regular Power-On Practice | If Left Idle Too Long |

|---|---|

| Power on 10–20 minutes before use to achieve thermal balance. | Startup lags, with large cold bias drift. |

| Energize the unit every few months during storage. | Capacitors degrade, increasing risk of failure. |

| Increase activation in humid or extreme climates. | Moisture and cycling create drift and instability. |

| Use each power-on to check data output and system health. | Problems stay hidden until deployment, leading to downtime. |

How Does Regular Power-On Extend the Lifetime of a Fiber Optic IMU?

A fiber optic IMU is like a finely tuned instrument—it performs best when kept active. Regular powering prevents the device from suffering cold-start shocks, which often place sudden stress on laser sources and analog circuits. By easing these transitions, the IMU remains more stable across its entire operational life.

Another key benefit is in maintaining the consistency of the optical signal path. Laser diodes and photodetectors work within tight tolerances, and inactivity can cause their characteristics to drift. Routine activation keeps these elements aligned, reducing the need for extended recalibration.

Finally, long-term reliability is reinforced through periodic bias refresh. Instead of allowing errors to accumulate silently, powering on ensures that bias models are continually updated, keeping the system ready for fast deployment. Over the years, this practice translates into fewer malfunctions, lower maintenance costs, and a significantly longer service lifetime.

Keeping Your Fiber Optic IMU Mission-Ready

Regular power-on is the simplest way to secure the long-term performance of a fiber optic IMU. It maintains thermal stability, refreshes bias calibration, and protects sensitive electronics—all of which directly translate into faster startups, higher accuracy, and longer life.

Key Takeaways:

- Thermal stabilityis essential for bias accuracy.

- Bias models stay freshonly with periodic activation.

- Electronics last longerwhen capacitors and circuits are cycled.

- Regular checks reduce surprises, ensuring mission readiness.

At GuideNav, our fiber optic IMUs are built with fast warm-up and robust self-tests, making them especially effective when paired with a disciplined power-on routine. If your applications demand precision without compromise, GuideNav is ready to support your mission.