A Fiber Optic Gyroscope-based IMU (FOG IMU) is engineered for long-term precision, yet no sensor remains perfectly stable forever. Over years of operation, factors such as optical source aging, thermal cycling, and mechanical stress gradually introduce bias drift and scale factor deviation. These subtle changes often go unnoticed until navigation accuracy begins to degrade, sometimes leading to costly downtime or mission failure. The key to avoiding this is proactive maintenance—knowing when recalibration restores accuracy and when replacement ensures reliability.

Recalibrate your FOG IMU every 12–24 months to maintain bias stability. Replace it after 5–8 years or when drift exceeds specifications to ensure long-term navigation reliability.

A FOG IMU rarely fails outright—it drifts gradually as optical fibers, laser diodes, and signal circuits age over time. These subtle changes in bias and scale factor can quietly reduce navigation accuracy. Understanding when performance begins to shift helps determine whether recalibration can restore precision or if replacement is the more dependable option.

Table of contents

Why Do FOG IMUs Need Recalibration at All?

Although a FOG IMU has no moving parts, its internal components are not immune to gradual change. The optical source weakens with age, the fiber coil accumulates microscopic stress, and temperature cycling slightly alters the refractive properties of the fiber. Over time, these small variations lead to bias drift and scale factor deviation.

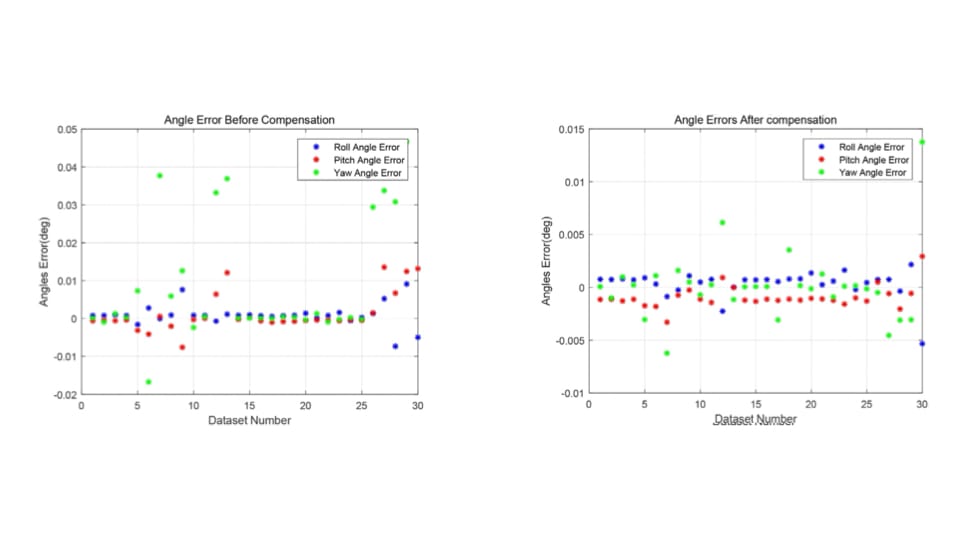

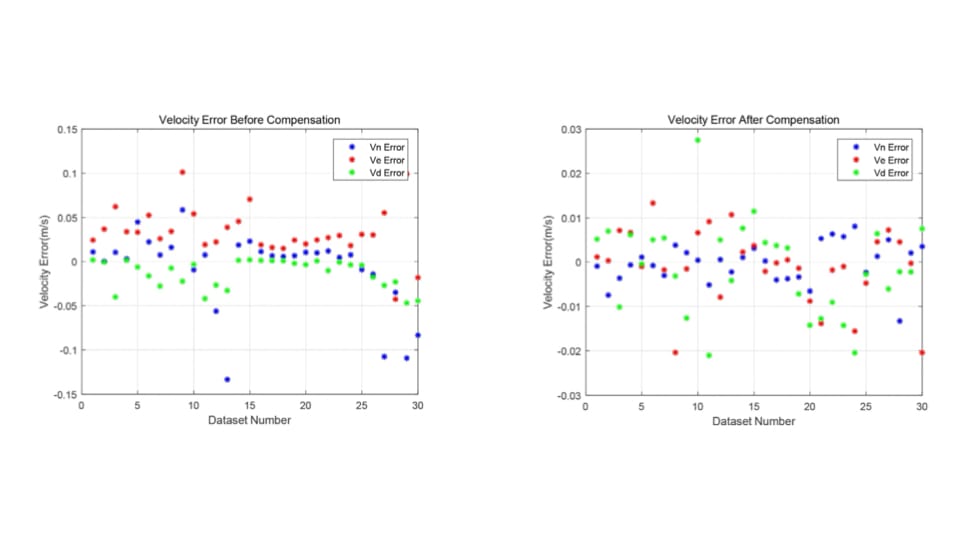

Recalibration is the process of identifying and compensating for these shifts. It restores the IMU’s original performance and stability by re-establishing its reference parameters under controlled conditions. Without periodic recalibration, accumulated errors can eventually compromise navigation accuracy and long-term reliability.

How Often Should a FOG IMU Be Recalibrated?

Even though a FOG IMU is known for long-term stability, its calibration interval still depends on how and where it operates. Factors such as vibration, temperature range, and mission duration can significantly affect drift performance over time. Setting the right recalibration schedule prevents accuracy degradation and extends the unit’s service life.

| Operating Condition | Recommended Interval | Reason / Notes |

|---|---|---|

| Defense, Aerospace, or Surveying Applications | Every 12–18 months | Maintains high precision under frequent use and changing environments. |

| Industrial or Laboratory Environments | Every 24 months | Low vibration and stable temperature reduce calibration drift. |

| High Vibration or Thermal Cycling | Every 6–12 months | Frequent shock and temperature variation accelerate bias drift. |

| After Major Mechanical Impact or Overload | Immediately | Sudden shocks can alter fiber coil symmetry and bias alignment. |

Regular recalibration keeps bias stability, scale factor accuracy, and thermal compensation within factory specifications, ensuring long-term navigation reliability.

What Are the Typical Signs That a FOG IMU Needs Recalibration?

Over time, small deviations begin to show in the IMU’s output, even if the unit still appears to function normally. Recognizing these early indicators of drift allows timely recalibration before performance degradation affects navigation accuracy.

Common warning signs include:

- Increased bias driftcompared to the original datasheet value.

- Heading offset or slow alignment errorafter each power-up.

- Growing position or attitude errorduring extended static or dead-reckoning tests.

- Temperature-dependent instability, where accuracy fluctuates as the unit warms up.

- Inconsistent scale factorwhen compared to reference rotation or test platforms.

If any of these symptoms appear repeatedly, factory recalibration should be scheduled immediately to restore full specification performance.

How Is FOG IMU Recalibration Performed?

Recalibration is a controlled, multi-step process that restores the IMU’s original accuracy by removing accumulated bias, temperature drift, and alignment errors. It must be carried out in a stable laboratory environment using precision instruments.

Static Bias Testing

The IMU is placed in a completely static condition for several hours. This test measures and resets the zero-rate output, defining a new baseline for bias stability.

Temperature Cycling

The unit is exposed to a full thermal range—typically –40°C to +85°C—to rebuild its temperature compensation model and verify long-term thermal stability.

Rotation Table Calibration

Using a high-precision rate table, the IMU is rotated at various speeds to correct its scale factor linearity and validate its angular rate accuracy.

Cross-Axis Alignment Check

This stage detects and compensates for small misalignments between orthogonal axes, ensuring accurate motion measurement across all directions.

System Verification

Finally, the new calibration data is compared with factory reference records. Only when all parameters meet tolerance limits is the IMU approved for operational return.

After these procedures, the FOG IMU regains its original bias precision, thermal stability, and dynamic accuracy.

Can Users Perform Field Recalibration Themselves?

A complete recalibration of a FOG IMU requires specialized optical alignment equipment, temperature-controlled facilities, and reference rotation tables—conditions that are rarely available outside the factory. Therefore, full recalibration cannot be performed in the field without compromising accuracy.

That said, users can still perform basic maintenance routines to monitor and stabilize performance. These include conducting short static bias checks, allowing the IMU adequate warm-up time before operation, and using any available onboard compensation functions to offset small temperature or alignment variations. While these methods help maintain consistency, they cannot replace factory-level calibration when long-term drift becomes noticeable.

What Is the Typical Lifespan of a FOG IMU?

A high-quality FOG IMU generally lasts 5–8 years, though its exact lifespan depends heavily on how it is used and maintained.

Because FOG IMUs rely on optical components instead of mechanical parts, aging occurs through gradual laser diode fatigue, optical power loss, and thermal stress within the fiber coil.

| Operating Condition | Typical Lifespan | Performance Notes |

|---|---|---|

| Continuous harsh-duty use | 4–5 years | Optical and thermal stress accumulate quickly. |

| Regular field use | 5–8 years | Periodic operation delays component fatigue. |

| Occasional laboratory use | 8–10 years | Stable environments preserve long-term accuracy. |

| Long storage without power cycling | May degrade early | Lack of optical activation shortens diode life. |

Proper storage, monthly power activation, and scheduled recalibration can significantly extend a FOG IMU’s reliable operating life.

What Happens If a FOG IMU Is Not Recalibrated for Years?

A FOG IMU may continue functioning for years without obvious faults, but its accuracy slowly declines beneath the surface. As bias errors, scale factor drift, and temperature compensation shifts accumulate, navigation data becomes less reliable. Without recalibration, internal models that once kept the system stable begin to diverge from reality.

| Time Without Recalibration | Observed Effects | Impact on Performance |

|---|---|---|

| 1 – 2 years | Minor bias drift and heading offsets. | Slight accuracy loss; easily recoverable. |

| 3 – 4 years | Attitude and position drift during long runs. | Significant degradation; recalibration required. |

| 5+ years | Thermal model failure and optical power decay. | Severe accuracy loss; replacement recommended. |

Unattended drift does not cause an immediate malfunction, but it silently erodes precision over time. Routine factory recalibration keeps the FOG IMU within its original performance limits.

When Is It Better to Replace Instead of Recalibrate?

Recalibration restores precision only when internal components remain healthy. Once optical degradation or electronic instability occurs, replacement becomes the safer, more economical choice.

Replacement is recommended when:

- Ifthe optical source or detector output has dropped significantly → Then the IMU can no longer maintain bias stability even after recalibration.

- Ifbias instability exceeds 10× the original specification → Then drift will remain even after recalibration, indicating irreversible optical aging.

- Ifthe IMU has suffered from shock, water, or humidity damage → Then internal stress may have permanently altered fiber geometry.

- Ifrecalibration costs exceed 25% of a new model’s price → Then upgrading to a modern, low-SWaP unit is usually more economical.

How Can You Monitor FOG IMU Health in Real Time?

Monitoring a FOG IMU’s health helps detect early signs of drift before accuracy is affected. Regular bias checks, temperature correlation tests, and scale factor verification reveal gradual performance changes. For advanced units, tracking optical power output and maintaining performance logs provide clear indicators of aging.

What’s the Best Maintenance Routine for Long-Term Reliability?

Long-term reliability depends on regular use and proper handling. Powering on the IMU periodically keeps the optical path active, while a brief warm-up before operation ensures stable bias output. The unit should be stored in a dry, vibration-free environment with minimal mounting stress.

A factory recalibration every 18–24 months keeps bias and scale factor within tolerance. With sealed optics and self-diagnostic design, modern FOG IMUs like the GuideNav Products make long-term maintenance simple and predictable.