Over the past 15 years in the inertial navigation industry, I’ve seen a wide range of IMU pricing based on various factors, including the type of gyroscope technology, accuracy, and application. Whether you are looking for an IMU for military, aerospace, or industrial applications, understanding the pricing structure is key to ensuring you make the right investment.

The price range for Inertial Measurement Units (IMUs) depends on the technology used and the level of accuracy. Basic MEMS IMUs typically range from $20 to $1,000. Higher-precision MEMS IMUs range from $1,000 to $10,000. Fiber Optic Gyroscope (FOG) IMUs usually cost between $10,000 and $100,000. High-end military-grade IMUs with some specialized systems can exceed $100,000.

In this article, I’ll break down the factors that affect IMU pricing and give you a clearer idea of what you can expect to pay based on your specific needs.

Table of contents

What Factors Influence the Price of an Inertial Measurement Unit (IMU)?

The price of an Inertial Measurement Unit can vary widely depending on several factors, which include the type of IMU, sensor accuracy, and specific features offered. Below are the key factors that affect the pricing of inertial measurement units.

1. Sensor Technology

The type of sensors used in an Inertial Measurement Unit plays a crucial role in determining the unit’s price. IMUs typically consist of gyroscopes, accelerometers, and sometimes magnetometers. The performance and technology of these sensors directly affect both the cost and accuracy of the IMU.

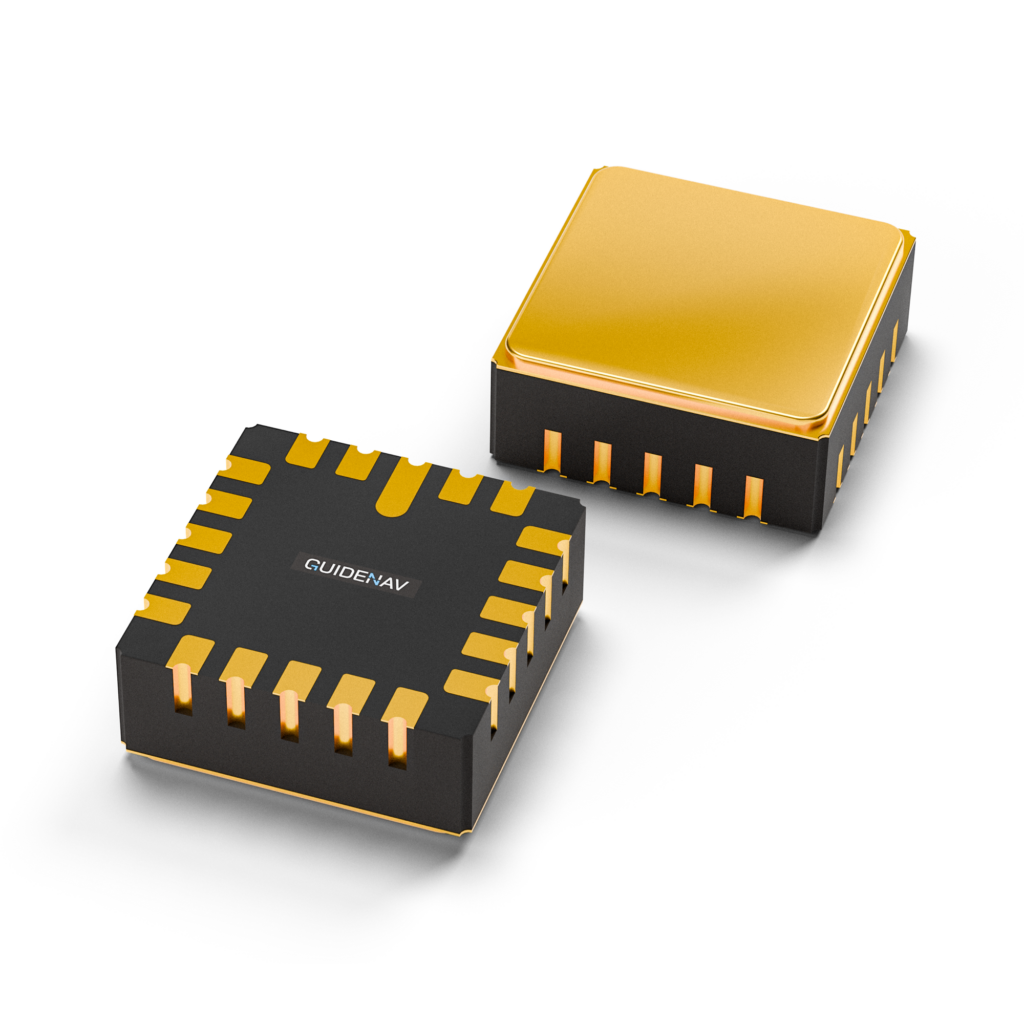

MEMS Sensors: Micro-Electro-Mechanical Systems (MEMS) sensors are widely used in consumer-grade IMUs due to their small size, low cost, and sufficient accuracy for many applications (e.g., smartphones, fitness trackers). In recent years, however, high-precision MEMS IMUs have emerged, such as GUIDENAV’s GUIDE900, which can provide 0.1°/h accuracy, making them competitive with entry-level FOG IMUs in terms of precision, while still maintaining a more affordable price point.

Fiber Optic Gyroscopes (FOGs): These sensors are typically used in higher-grade IMUs that require higher accuracy and stability over long periods. FOGs provide sub-degree per hour accuracy and are commonly used in applications like navigation systems in aerospace and defense.

Ring Laser Gyroscopes (RLGs): These are among the most accurate sensors available, commonly used in the most demanding navigation systems. They are expensive due to their complex design and the high level of precision they offer.

2. Accuracy and Precision

The accuracy of the IMU’s sensors is perhaps the most important factor influencing its price. High-precision IMUs that deliver extremely low error rates in angular velocity and acceleration are typically more expensive. The more accurate the gyroscope, the more expensive the IMU.

3. Manufacturing Process and Materials

IMUs with higher accuracy require more sophisticated manufacturing techniques and better materials. For instance, high-quality materials like quartz or fiber optics are used in military-grade and navigation-grade gyroscopes, adding to their cost. The complexity of assembling and testing these components also increases the final price.

MEMS-based IMUs are mass-produced using standard semiconductor manufacturing techniques, which makes them less expensive.

FOGs and RLGs require specialized manufacturing processes and often involve labor-intensive calibration procedures, leading to a higher price point.

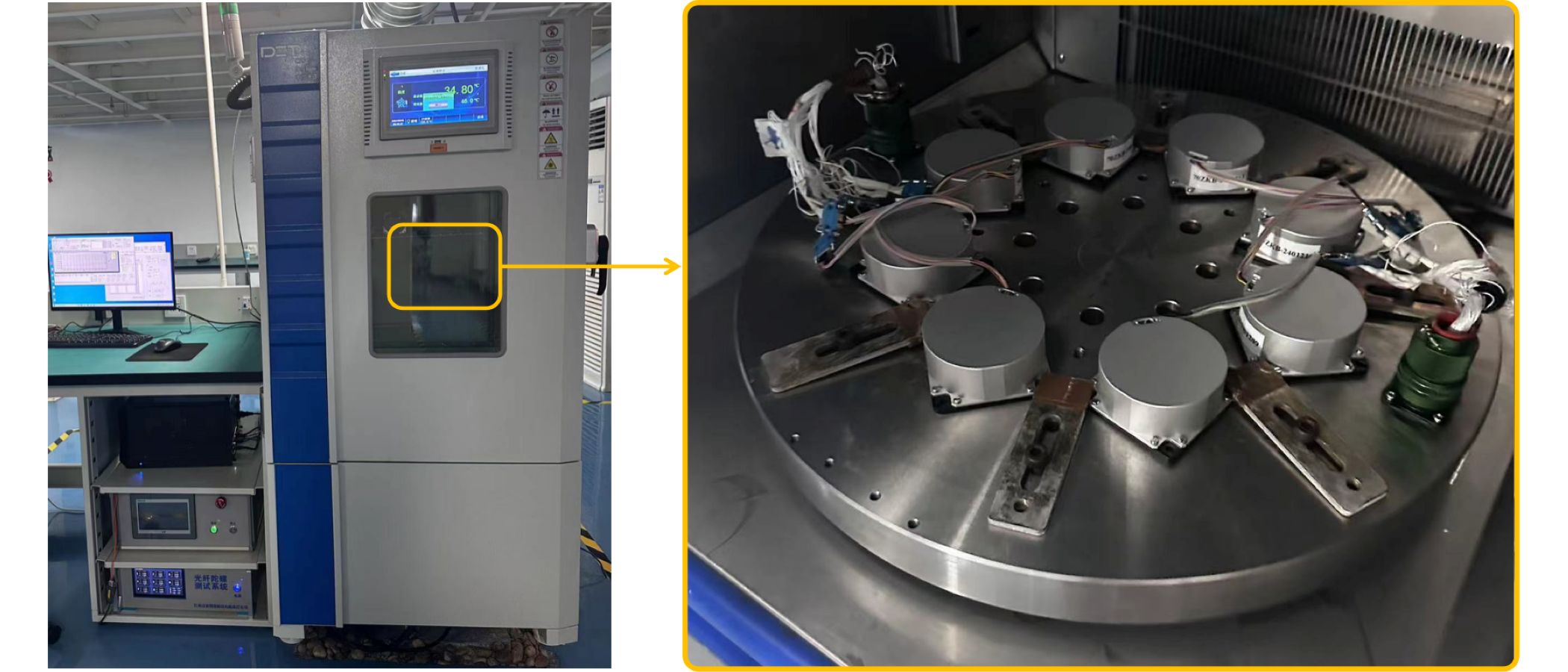

4. Calibration and Testing

The calibration process is essential for ensuring that an IMU performs accurately under various conditions. Higher-precision IMUs require more advanced calibration techniques to minimize errors caused by temperature changes, mechanical vibrations, and other environmental factors.

Low-precision IMUs (like consumer-grade MEMS) require minimal calibration, making them cheaper.

High-precision IMUs require extensive calibration procedures, including temperature compensation, bias stabilization, and multi-axis alignment. These processes add both time and cost to the final product.

In addition, more accurate IMUs must undergo rigorous testing under extreme conditions (e.g., high and low temperatures, shock, and vibration tests), which also contributes to higher prices.

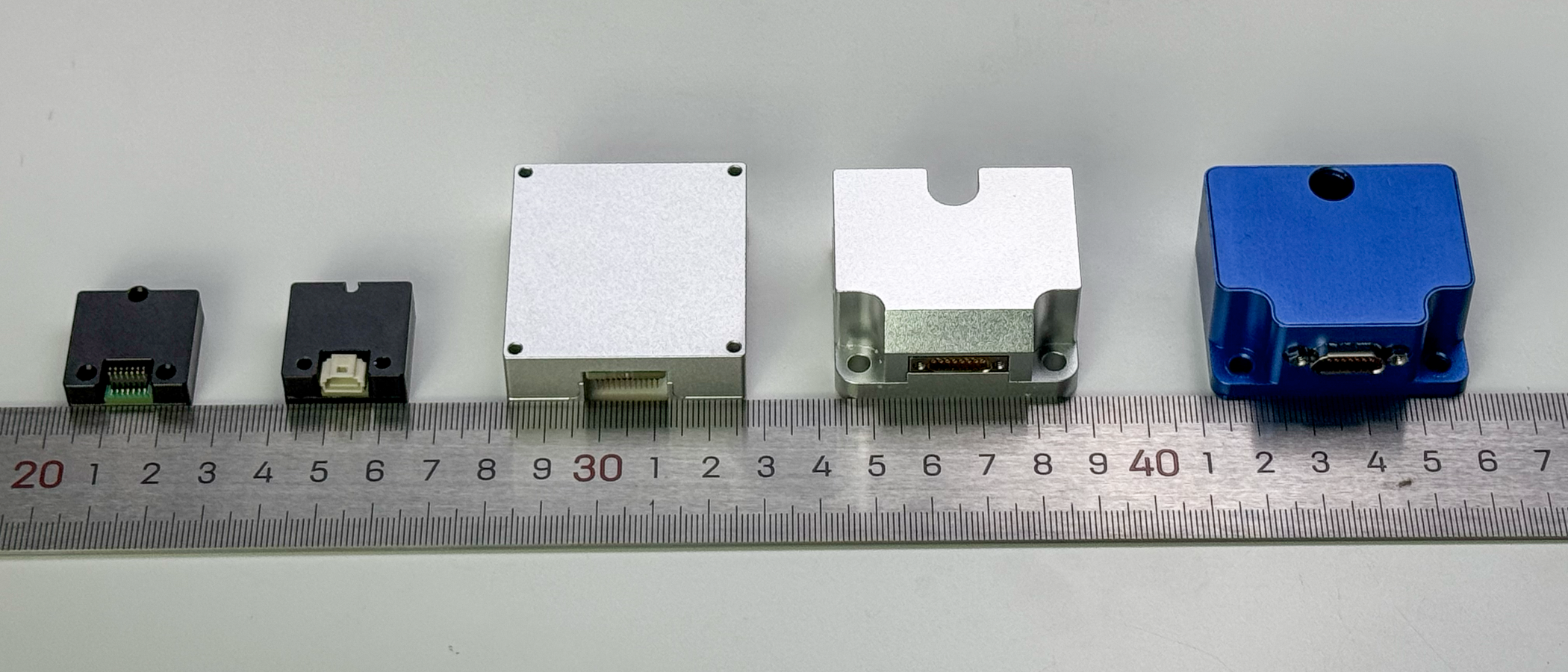

5. Size and Weight

The size and weight of the IMU are influenced by the complexity of its components. While consumer-grade IMUs are typically small and lightweight (thanks to MEMS technology), industrial-grade and military-grade IMUs tend to be bulkier due to their need for more precise components, power supplies, and protective casings.

Small, compact IMUs are generally less expensive as they can be mass-produced.

Larger IMUs that need extra protection, such as shock-resistant housings for industrial or military use, or those used for high-end applications, are more expensive to produce and integrate.

6. Environmental Protection and Durability

IMUs that are designed to operate in extreme conditions (e.g., high shock, vibration, temperature extremes) typically cost more. This is due to the need for ruggedized housings and environmental protection features to ensure that the device operates reliably in harsh conditions.

Consumer-grade IMUs are generally not built to withstand tough environments and are made with standard plastic enclosures, which keeps costs down.

Industrial-grade and military-grade IMUs are often equipped with sealed enclosures, temperature compensation, and vibration resistance to ensure the sensors stay accurate over time. These additional features increase both the complexity and the cost of manufacturing.

7. Customization

Inertial Measurement Units often need to be customized for specialized applications to meet specific requirements. This could include adjusting the accuracy, size, or interface options, or integrating the IMU into a larger system. Custom-built IMUs typically have a higher price tag due to the engineering work required to tailor the unit to the customer’s needs.

For example, in aerospace or military applications, IMUs may need to meet specific certification standards or be designed to function in particular environments. Customization for these types of applications usually involves higher production costs.

| IMU Type | Typical Price Range | Primary Use | Accuracy |

|---|---|---|---|

| Low-End MEMS IMUs | $20 - $1,000 | Consumer electronics, robotics | Moderate accuracy |

| High-Precision MEMS IMUs | $1,000 - $10,000 | Military, aerospace, high-performance | High precision |

| Fiber Optic Gyroscope (FOG) | $10,000 - $100,000 | Aerospace, defense, high-reliability | High precision |

| Ring Laser Gyroscope (RLG) | $50,000 - $100,000+ | Military, missile guidance, aerospace | Ultra-high precision |

- Low-End MEMS IMUs: These are the most affordable and are used in consumer electronics or low-cost navigation systems. Prices typically fall between $100 and $1,000 for these basic systems.

- High-Precision MEMS IMUs: These advanced MEMS IMUs offer high accuracy and can be used in military, aerospace, and industrial applications. Prices for these IMUs range from $1,000 to $10,000, offering a great balance between affordability and high performance.

- Fiber Optic Gyroscope (FOG)-Based IMUs: FOG-based systems provide exceptional accuracy and are often used in demanding applications such as aerospace, military navigation, and submarine guidance. These systems typically cost between $10,000 and $100,000.

- Ring Laser Gyroscope (RLG)-Based IMUs: These are the most expensive IMUs, designed for military-grade systems or high-precision aerospace applications where sub-micro radian accuracy is required. Prices for RLG IMUs can exceed $50,000, with some specialized systems exceeding $100,000.

Inertial Measurement Unit Accuracy Grade

Inertial Measurement Units vary in accuracy depending on their grade, with consumer-grade IMUs having lower accuracy (10°/h to 100°/h) and navigation-grade IMUs providing extremely high precision (0.0001°/h to 0.01°/h). By choosing the right grade of IMU, you can meet the specific accuracy requirements for your application.

| Inertial Measurement Unit Grade | IMU Type | Gyroscope Accuracy (°/h) | Typical Applications |

|---|---|---|---|

| Consumer Grade | MEMS IMU | 10°/h ~ 100°/h | Smartphones, gaming devices, sports tracking, basic navigation |

| Industrial Grade | MEMS IMU or low-end Fiber Optic Gyroscope (FOG) | 1°/h ~ 10°/h | Drones, robotics, industrial automation, general navigation |

| Military Grade | Fiber Optic Gyroscope (FOG) or Ring Laser Gyroscope (RLG) | 0.01°/h ~ 0.1°/h | Missile guidance, military aircraft, tactical navigation, aerospace systems |

| Navigation Grade | High-end Fiber Optic Gyroscope (FOG) or Ring Laser Gyroscope (RLG) | 0.0001°/h ~ 0.01°/h | Commercial aviation, marine navigation, precision surveying |

How Does Inertial Measurement Unit (IMU) Accuracy Affect Pricing?

The accuracy required for an IMU directly affects its cost. IMUs used for military, aerospace, or missile guidance applications typically require sub-micro to nano-radian precision, which adds to the cost of the system. The higher the precision needed, the more you will pay.

| Accuracy Level | Application | Price Range |

|---|---|---|

| Low to Moderate | Consumer electronics, basic navigation | $20 - $1,000 |

| High Precision | Industrial robotics, military, aerospace | $1,000 - $50,000 |

| Ultra-High Precision | Military, missile guidance, aerospace | $50,000 - $100,000+ |

- Low to Moderate Accuracy: For basic applications, such as consumer electronics or low-cost robotics, a basic MEMS IMU with moderate accuracy is sufficient. These systems are priced in the $20 to $1,000

- High Precision: Systems requiring high precision for applications such as industrial robotics or aerospace typically range from $1,000 to $50,000.

- Ultra-High Precision: Military and aerospace-grade systems that need sub-micro radian accuracy typically fall into the $50,000 to $100,000 range, with some systems exceeding $100,000 for extremely demanding applications like missile guidance or high-precision navigation.

Are Inertial Measurement Unit Prices Affected by Application?

As in any industry, the application of an IMU significantly influences its pricing. Below, I’ve categorized different sectors and their typical IMU needs:

| Application | IMU Type | Price Range | Features |

|---|---|---|---|

| Military & Defense | High-Precision MEMS, FOG, RLG | $10,000 - $100,000+ | High accuracy, rugged, ITAR compliant |

| Aerospace | FOG, RLG, High-Precision MEMS | $10,000 - $100,000+ | High Accuracy, Temperature & vibration resistant |

| Industrial | Low to High-Precision MEMS | $1,000 - $10,000 | Basic to moderate accuracy, robust |

| Consumer Electronics | Low-End MEMS | $100 - $1,000 | Moderate accuracy, cost-effective |

- Military & Defense: IMUs used in military systems need to meet high standards of accuracy, durability, and environmental resistance, which can push the price to $10,000 – $100,000. Some military-grade IMUs can exceed this range based on customization and security features.

- Aerospace: Aerospace IMUs, used in systems like aircraft navigation and satellite control, often need to withstand extreme temperatures, high altitudes, and vibrations. These systems typically fall into the $10,000 – $100,000+.

- Industrial Applications: For industries like robotics and automated systems, the required accuracy is typically lower than military and aerospace applications, which makes them more affordable—ranging from $1,000 to $10,000 depending on the complexity and performance requirements.

Does the Customization of IMUs Impact the Price?

Many clients require customized IMUs to meet specific needs. Customization is a key factor that drives up the cost of an IMU. The more specialized your requirements, the higher the price. For example, if you need a high-accuracy IMU with specific features like temperature resistance or shock durability, or if you require integration with complex systems, the price can increase. Custom features may include:

- Environmental protection(e.g., sealing for water resistance or shockproof designs).

- Multi-sensor fusion(to improve performance in harsh environments).

- Special softwareintegration for data analysis and remote monitoring.

Customization often increases the price by 20% to 30% or more depending on the complexity of the requirements.

How Does Bulk Purchasing Affect IMU Prices?

For larger companies or military organizations purchasing IMUs in bulk, volume discounts can significantly reduce the cost per unit. Depending on the contract terms and the number of units required, long-term relationships with suppliers can also result in more favorable pricing.

How Can GuideNav Help?

At GuideNav, we specialize in providing high-precision Inertial Measurement Units (IMUs), MEMS gyroscopes, and Fiber Optic Gyroscopes (FOGs), offering industry-leading solutions for applications in defense, aerospace, and industrial sectors. Here’s how we can help:

High Precision IMUs for Critical Applications

Whether you’re working on military navigation systems, satellite guidance, or high-performance robotics, our IMUs deliver exceptional accuracyand reliability. We offer MEMS-based IMUs for cost-effective solutions and FOG-based IMUs for top-tier performance in demanding environments like aerospace and defense.

Customizable Solutions

Every project has unique needs, and GuideNav’s customization serviceis designed to ensure our products fit precisely into your system. Whether you need specific hardware configurations, special performance requirements, or integration into complex systems, our team works directly with you to provide tailored solutions that meet your exact needs.

Competitive Pricing

Unlike many other high-precision IMU manufacturers, we offer cost-effective pricingwithout compromising on quality. GuideNav’s solutions are priced competitively compared to industry standards, allowing you to access top-tier technology at a fraction of the cost.