“Should we go with MEMS or FOG?”—it’s the question I hear most, and not because people don’t know the specs. What’s uncertain is what actually matters in practice: is it drift, shock resistance, or just budget? And too often, the wrong call doesn’t fail outright—it fails quietly, until it’s too late to recover.

MEMS IMUs are smaller, lighter, and more cost-effective, making them ideal for space- and power-constrained systems. FOG IMUs, by contrast, deliver significantly better bias stability, lower drift, and superior performance in harsh or GNSS-denied environments.

The trade-offs aren’t obvious—let’s walk through what really matters.

Table of contents

How Do MEMS And FOG Gyroscopes Work?

MEMS gyroscopes measure motion by detecting tiny shifts in a vibrating silicon structure—like sensing how a tuning fork wobbles when turned. They’re built on micro-scale chips, making them compact, energy-efficient, and affordable.

FOG gyroscopes, on the other hand, rely on light. They send laser beams through a long coil of optical fiber; when the device rotates, the beams shift slightly out of sync—a phenomenon called the Sagnac effect. This allows FOGs to detect rotation with exceptional accuracy, zero moving parts, and extreme stability over time.

MEMS vs FOG: How To Choose The Right One?

Choosing between MEMS and FOG doesn’t have to be complex—by focusing on a few key performance factors, you can quickly narrow down the right fit for your application.

1. Accuracy

When evaluating accuracy, the most critical parameters are bias stability, and angle random walk (ARW). Below is a comparison of GuideNav’s products based on these key metrics.

| Parameter | MEMS | FOG |

|---|---|---|

| Bias Stability (°/h) | 0.05 ~ 3 | 0.003 ~ 0.5 |

| Angle Random Walk (°/√h) | 0.05 ~ 0.45 | 0.0002 ~ 0.02 |

2. Size & Weight

MEMS are compact and lightweight for space-constrained systems, while FOG are larger and heavier, suited for high-end or fixed platforms.

3. Power Consumption

MEMS typically consume less than 1W, making them ideal for battery-powered and mobile platforms. In contrast, FOG can require over 10W due to their laser-based optical systems and often demand additional thermal management—based on comparative data from GuideNav’s product portfolio.

4. Long-Term Stability

Closed-loop FOG offer superior long-term precision and environmental resilience, while MEMS , though advancing in compensation techniques, still lag in sustained stability.

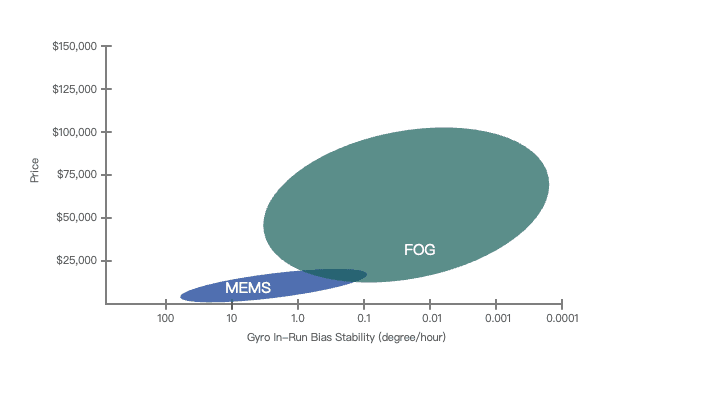

5. Cost

MEMS are cost-effective and suitable for high-volume applications, while FOG are substantially more expensive and targeted at high-end, precision-critical markets.

Having outlined the primary distinctions in accuracy, form factor, power efficiency, long-term stability, and cost, a comprehensive side-by-side comparison is presented in the table below to support more informed evaluation.

| Feature | MEMS IMU | FOG IMU |

|---|---|---|

| Technology | Silicon-based micromechanical sensors | Optical gyros using fiber coils and light interference |

| Size & Form Factor | Very compact, suitable for space-limited designs | Bulkier form due to fiber routing and optics |

| Accuracy | Moderate accuracy for general use | High precision suitable for critical systems |

| Cost | Low cost, ideal for volume production | Significantly higher cost due to complexity |

| Power Consumption | Highly efficient with minimal power draw | Consumes more power, typically for high-end use |

| Typical Applications | Drones, wearables, automotive, consumer devices | Defense, aerospace, marine, high-end industrial |

| Operating Principle | Detects motion via vibrating mass structures | Uses the Sagnac effect to detect angular velocity |

| Environmental Stability | Sensitive to heat and vibration over time | Highly resistant to thermal drift and mechanical stress |

| Precision Level | Adequate for short-term or assisted navigation | Maintains sub-degree heading for extended periods |

| Responsiveness | Fast and responsive in dynamic systems | Stable response; slightly slower than MEMS |

| Durability | Resilient but less stable under extreme conditions | Designed for extreme, mission-critical environments |

| Integration Effort | Simple to integrate with most platforms | Requires careful setup and system-level alignment |

Can MEMS Accuracy Surpass FOG?

From an expert’s point of view, FOG still leads in accuracy—especially in terms of bias stability and low noise. That’s why it remains the go-to choice for high-precision navigation.

But MEMS technology is catching up fast. Today’s tactical-grade MEMS gyros can reach:

- Bias instabilityas low as 05°/hr

- Angle random walkaround 01°/√hr

That puts them close to entry-level FOGs, but in a smaller, lighter, and much cheaper form factor.

While top-tier FOGs still outperform MEMS in ultra-precise and long-duration use cases, modern MEMS are now accurate enough for many demanding applications—especially when size, weight, power, and cost matter.

What Are The Real-world Use Cases For MEMS And FOG IMUs?

The choice between MEMS and FOG is ultimately shaped by what the system needs to withstand—and how much error it can tolerate over time. Below is a breakdown of where each technology fits in real-world deployments:

MEMS IMU Use Cases

MEMS IMUs are optimized for applications where size, weight, power consumption, and cost efficiency take precedence over ultra-high precision.

- Unmanned Aerial Vehicles (UAVs)

Ideal for small- and mid-size drones relying on GNSS for correction - Consumer and industrial robotics

Used for motion tracking, balance control, and orientation feedback - Automotive systems (ADAS, dead reckoning, stabilization)

When fused with GNSS or wheel encoders - Wearables and handhelds

Motion sensing in compact, battery-powered devices

MEMS performs well in systems where external correction is available and drift tolerance is acceptable.

FOG IMU Use Cases

FOG IMUs are selected where inertial accuracy must remain uncompromised under stress, isolation, or extended durations.

- Defense and military platforms

Tactical navigation, vehicle stabilization, missile and turret guidance - Marine and subsea systems

Long-endurance vessels, ROVs, and inertial navigation under GNSS outage - Space and aerospace applications

Launch platforms, satellites, and spacecraft attitude control - Surveying and precision drilling

Applications that require sub-degree heading over time without reset

FOG enables mission continuity where MEMS would drift beyond acceptable thresholds.

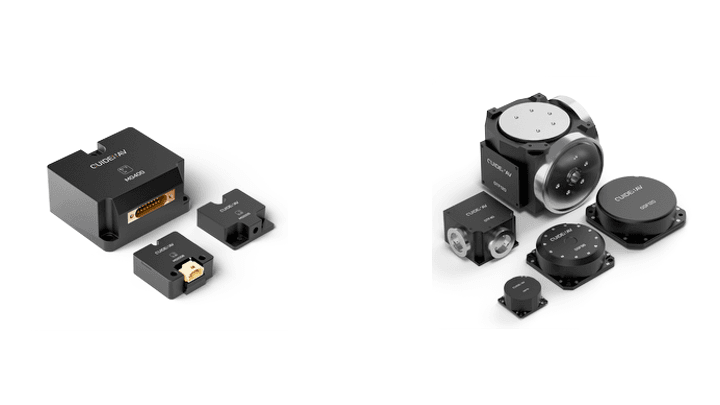

At GuideNav, we offer a comprehensive portfolio of both MEMS and FOG IMUs, designed to meet the diverse needs of commercial, industrial, and defense applications. Whether the priority is size and efficiency or long-term inertial precision, we provide options tailored to each performance envelope.

How Much More Expensive Is FOG Compared To MEMS?

FOG-based IMUs are generally 8 to 10 times more expensive than MEMS-based units. This price gap is driven by:

- High-cost components like fiber coils and interferometric optics

- Precision assembly requiring tight tolerances and calibration

- Low-volume production, unlike MEMS which benefit from mass manufacturing

In contrast, MEMS IMUs use cost-effective silicon processes and are easier to scale, resulting in prices often under one-tenth that of FOG systems.

How Do I Decide Whether I Need Mems Or Fog For My Project?

It depends on your application, required accuracy, and environment. At GuideNav, we provide both MEMS and FOG-based IMUs and INS systems, ranging from compact, cost-effective units to high-precision tactical-grade solutions.

To determine which sensor technology best fits your project, we recommend evaluating the following factors:

- Application details.

- Key performance requirements: (e.g., target bias stability, dynamic range, environmental conditions etc.)

Still unsure? Share your specs—we’ll recommend the best fit for your system.