Our MEMS based Inertial Measurement Unit

MEMS Inertial Measurement Unit

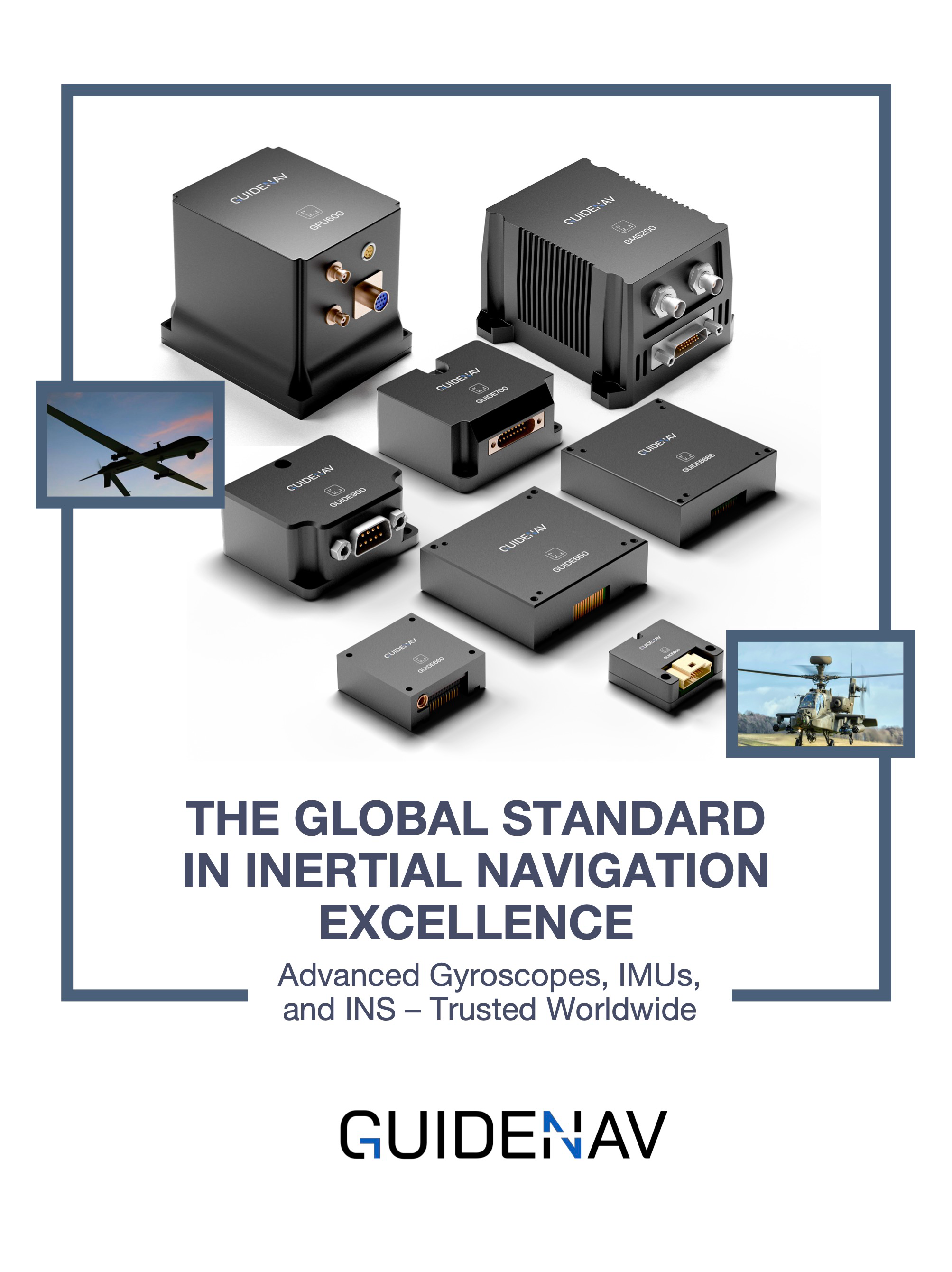

15,000+ Systems in Operation in 35+ Countries

Custom Solutions Trusted by Global Key Players

GuideNav’s MEMS Inertial Measurement Unit (IMU) represents the pinnacle of precision and reliability. Designed to deliver exceptional performance, our IMUs provide accurate measurements of angular velocity and linear acceleration, critical for navigation and control systems in aerospace, defense, and industrial applications.

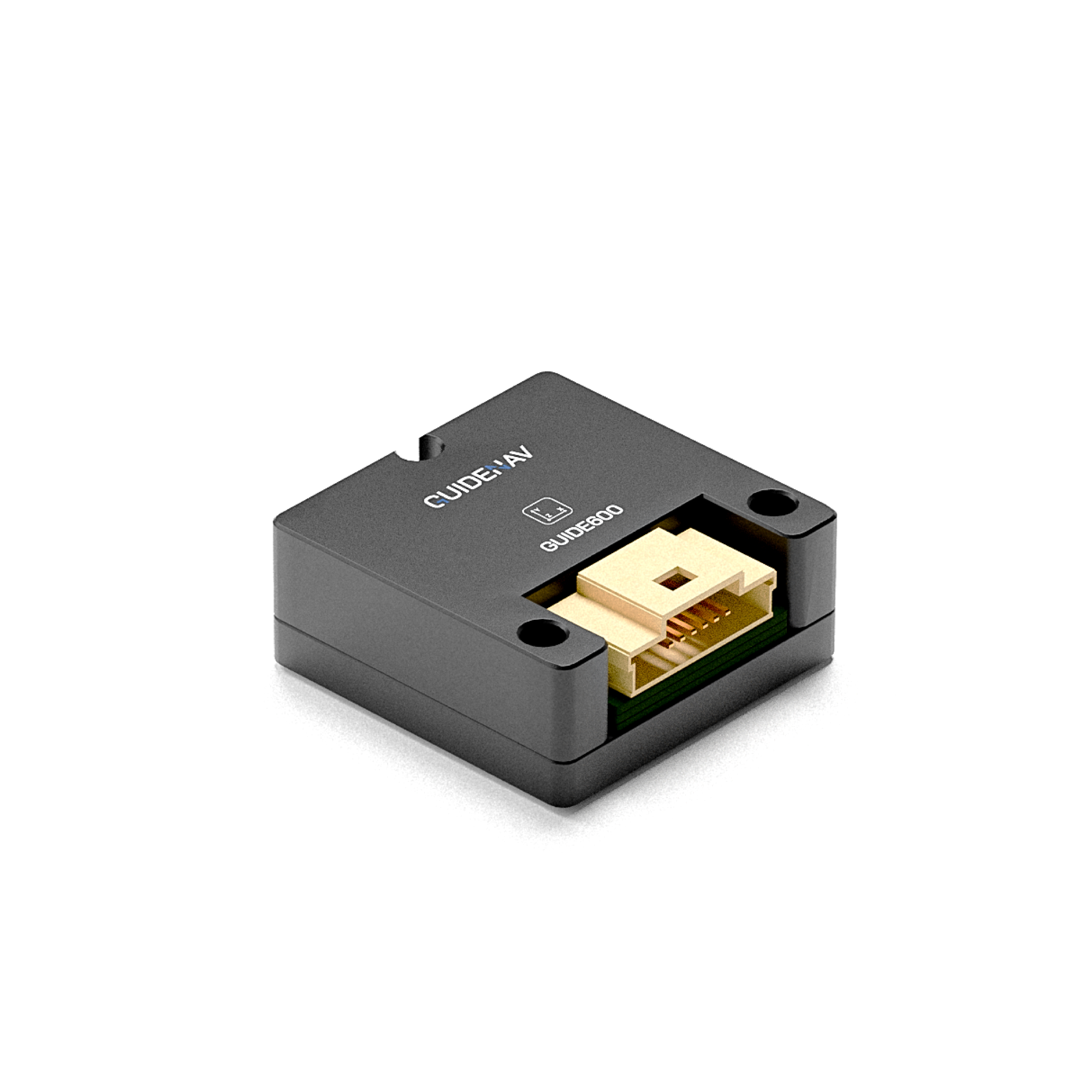

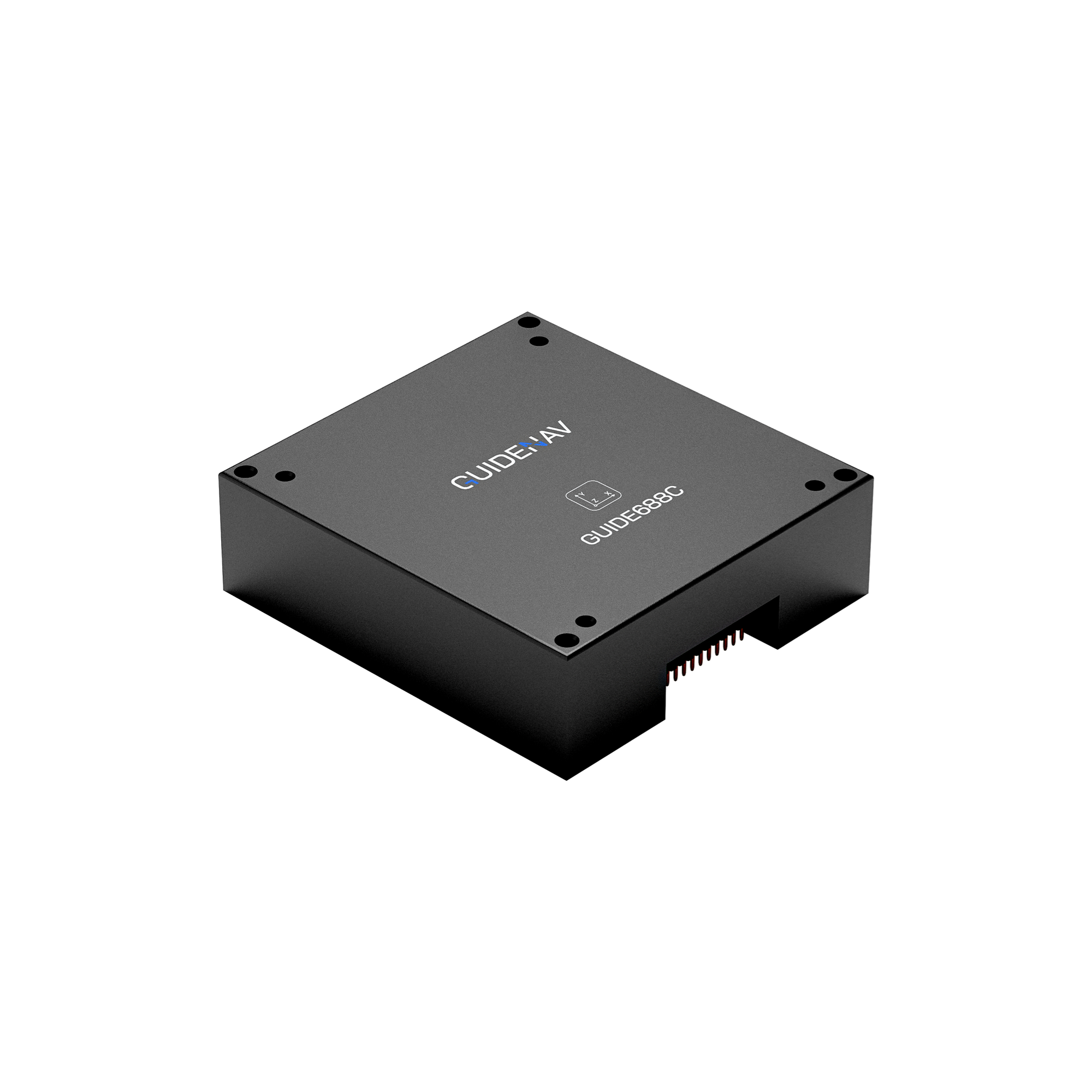

Guidenav‘s Featured MEMS inertial measurement unit Model

HIGH ACCURACY

MEMS IMU MODELS

As a leading manufacturer of MEMS IMU, GuideNav offers a full range of high-precision MEMS Inertial Measurement Units designed to meet the diverse needs of various industries, from aerospace and defense to industrial automation and robotics. Our solutions include both standard and custom IMUs, tailored to your specific needs.

We alsoprovide seamless replacement options for your existing systems, ensuring compatibility with your current interfaces without any integration challenges. Simply contact our experts to explore detailed specifications and customized solutions for your projects.

- Cost-effective

- Gyro range: ± 500 °/s

- Bias instability: ≤ 2 °/h

- Bias stability: ≤ 10°/h

- Weight: ≤ 10g

- Protocol: UART

- 10-axis MEMS IMU

- Gyro range: ± 450 °/s

- Bias instability: ≤ 2°/h

- Bias stability: ≤ 4°/h

- Weight: ≤ 40g

- Protocol: SPI

- 10-axis MEMS IMU

- Gyro range: ± 450 °/s

- Bias instability: ≤ 0.8 °/h

- Bias stability: ≤ 3°/h

- Weight: ≤ 40g

- Protocol: SPI

- Medium-High Accuracy

- Gyro range: ± 320 °/s

- Bias instability: ≤ 0.4 °/h

- Bias stability: ≤ 2°/h

- Weight: ≤ 10g

- Protocol: RS422

- Wide Gyro Range

- Gyro range: ± 2000 °/s

- Bias instability: ≤ 3 °/h

- Bias stability: ≤ 10°/h

- Weight: ≤ 30g

- Protocol: UART

- GUN-HARD to 20,000g

- Gyro range: Up to 6000 °/s

- Bias instability: ≤ 3°/h

- Bias stability: ≤ 10°/h

- Weight: ≤ 50g

- Protocol: UART

- High-accuracy

- Gyro range: ± 450 °/s

- Bias instability: ≤ 0.2 °/h

- Bias stability: ≤ 1°/h

- Weight: ≤ 40g

- Protocol: RS422

- Ultra-high Accuracy

- Gyro range: ± 400 °/s

- Bias instability: ≤ 0.1 °/h

- Bias stability: ≤ 0.5°/h

- Weight: ≤ 55g

- Protocol: RS422

Get Your Custom Solution Now

Your project deserves a solution tailored to your exact specifications. To ensure we provide the best Inertial Measurement Units (IMU) for your needs, we invite you to share the specific parameters and performance requirements of your applications. Whether it’s precision, stability, or size constraints, our team is ready to help you find the perfect fit.

Table of Contents

Download this page as a PDF

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the download link immediately.

Introducing Inertial Measurement Unit (IMU)

What is Inertial Measurement Unit (IMU)

An Inertial Measurement Unit (IMU) is an advanced sensor system that precisely tracks an object’s motion and orientation in three-dimensional space. It combines multiple sensors, typically accelerometers and gyroscopes, to measure linear acceleration and angular velocity, respectively. In some configurations, magnetometers are also integrated to provide additional orientation data relative to the Earth’s magnetic field.

IMUs play a crucial role in navigation and control systems across various high-stakes industries, such as aerospace, defense, and autonomous systems. By delivering real-time, high-precision data on position, velocity, and orientation, IMUs ensure that complex systems maintain stability and accuracy under dynamic conditions, enabling reliable performance even in environments with high levels of vibration, shock, or other disruptive forces.

EXPLORE MEMS Inertial Measurement Unit (MEMS IMU)

How Does a MEMS IMU Work?

A MEMS IMU (Inertial Measurement Unit) works by integrating multiple sensors, typically including MEMS accelerometers and gyroscopes, to measure motion and orientation. The accelerometer detects linear acceleration in three axes, while the gyroscope measures rotational movement around those axes. These sensors collect data on the object’s position, velocity, and orientation, which is then processed to provide precise real-time navigation and control information. MEMS IMUs are compact, energy-efficient, and highly accurate, making them ideal for applications in aerospace, defense, robotics, and autonomous systems.

Inertial Measurement unit vs Gyroscope (only)

Why Use a Complex MEMS IMU Instead of Just a Gyroscope?

While a gyroscope measures angular velocity, it suffers from drift over time and cannot provide absolute position or orientation. An IMU integrates accelerometers and magnetometers with the gyroscope to correct drift, provide initial orientation, and deliver comprehensive 3D motion data, ensuring accurate and reliable attitude measurement over time.

Drift Correction: Gyroscopes alone suffer from drift over time. An IMU includes accelerometers and magnetometers to correct this drift and maintain accuracy.

Initial Orientation: A gyroscope cannot provide initial orientation, but an IMU can, using accelerometers to detect gravity and magnetometers for heading.

Comprehensive 3D Motion Data: IMUs measure not just rotation but also linear acceleration, offering a full picture of motion in three dimensions.

Improved Accuracy: By combining data from multiple sensors, an IMU delivers more accurate and reliable attitude measurements, especially over long periods.

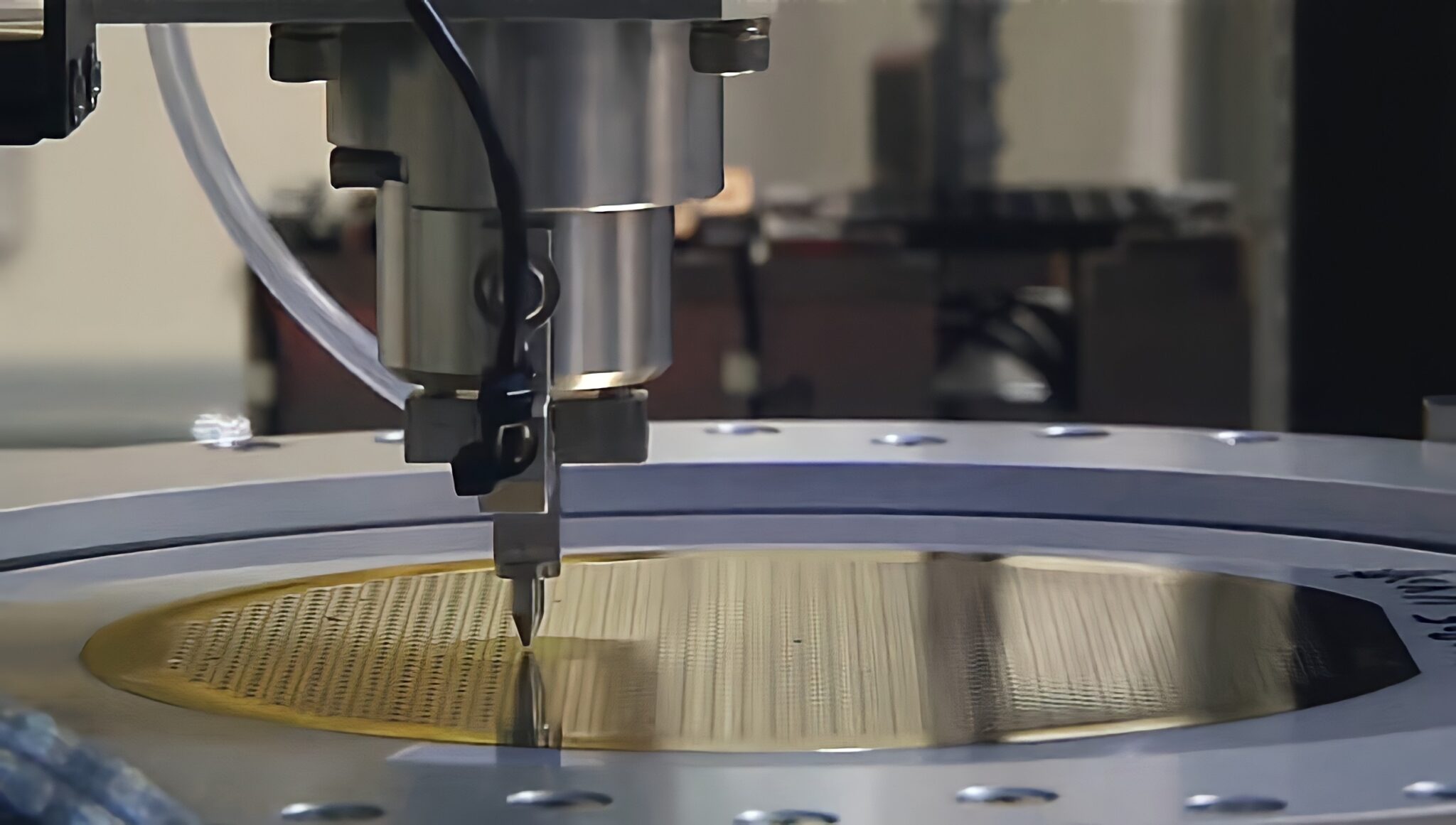

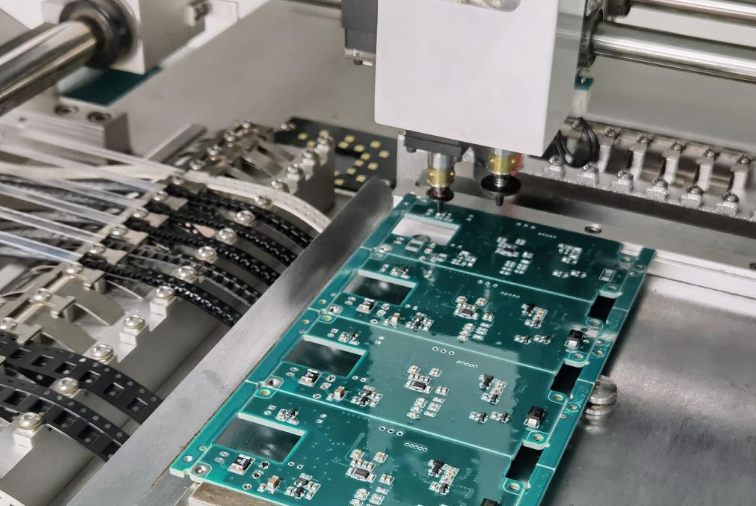

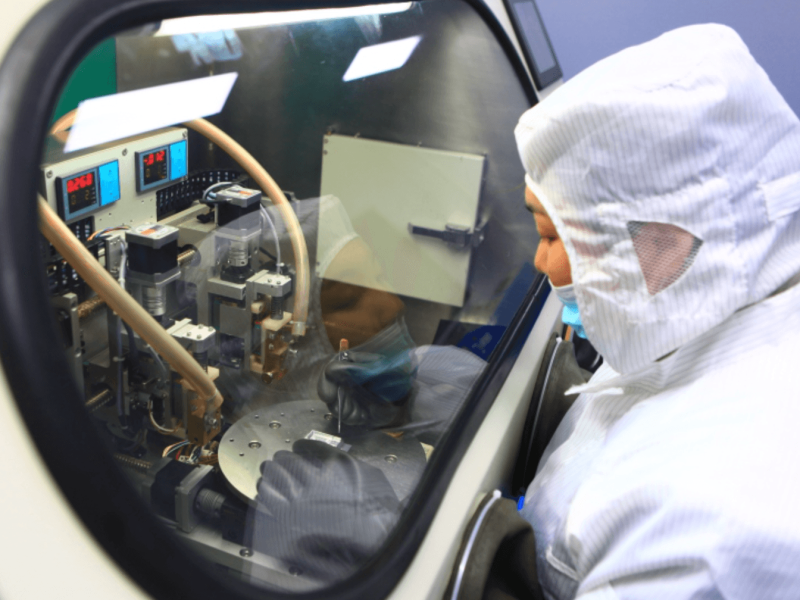

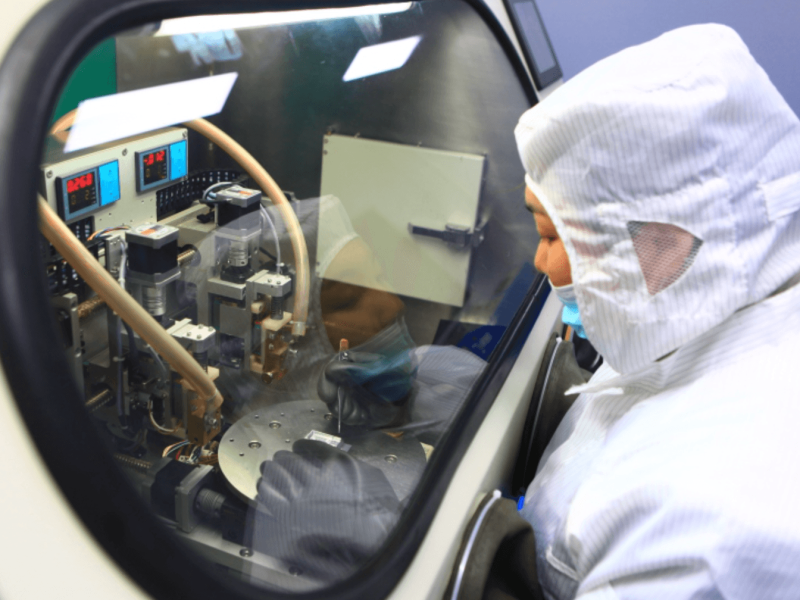

Manufacturing Process of Mems inertial measurement unit

Manufacturing Process of MEMS IMU

01

STEP 1 :Customer Customization & Parameter Definition

Define key parameters such as drift rate, noise density, temperature drift, and linearity based on the specific application requirements of the customer. Ensure these parameters meet the required precision, stability, and environmental adaptability. Design and manufacture the MEMS sensors, including accelerometers and gyroscopes, and integrate them into a single module.

02

STPE 2 :Circuit Design & Integration

Design and integrate the sensor signal processing circuits, including signal amplification, filtering, and analog-to-digital conversion. These functions are typically integrated into an ASIC or microcontroller for high-level integration.

03

STPE 3 :Automated Calibration

Perform zero-point calibration, dynamic testing, and temperature compensation on the accelerometers and gyroscopes using an automated testing platform to ensure sensor accuracy and stability.

04

STPE 4 :Packaging & Testing

Compactly package the MEMS chips and circuits, and conduct environmental adaptability testing, such as temperature, vibration, and shock tests, to ensure the IMU’s reliability and performance under various conditions.

EXPLORE MEMS Inertial Measurement Unit (MEMS IMU)

Does MEMS IMU Equal to 'Low Accuracy'?

Not necessarily. While standard MEMS IMUs are typically associated with moderate accuracy, high-precision tactical grade MEMS IMUs can achieve bias instability as low as 0.1°/hr (GUIDE900), a level comparable to entry-level Fiber Optic Gyroscope (FOG) IMUs.

- Standard MEMS IMUs: These are cost-effective and suitable for applications where moderate accuracy is sufficient, such as consumer electronics, industrial automation, and drones.

- High-Precision MEMS IMUs: With improved design and manufacturing processes, some advanced MEMS IMUs now meet the accuracy requirements of military-grade and aerospace applications. They can provide reliable performance in navigation systems, UAVs, and even guided defense systems.

However, it’s important to note that even high-precision MEMS IMUs still have limitations in long-term drift and ultra-high stability compared to FOG IMUs, which are better suited for mission-critical applications requiring the lowest possible drift and highest accuracy.

MEMS IMU VS FOG IMU Which is Better ?

FOG IMU: Remains the preferred choice for high-precision applications, especially where long-term stability is critical, such as in aerospace, precision navigation, and defense. Despite their larger size and higher cost, Fiber Optic Gyroscope IMUs excel in performance under extreme environmental conditions.

MEMS IMU: With advancements in technology, MEMS IMUs have reached accuracy levels comparable to mid-range FOG gyroscopes in many scenarios and are widely used in both military and high-precision civilian fields. Their strengths lie in miniaturization, low power consumption, and versatility across various applications.

| Feature | FOG IMU | MEMS IMU |

|---|---|---|

| Operating Principle | Measures angular velocity based on the Sagnac effect in fiber optic interference | Measures acceleration and angular velocity through micro-mechanical structures in MEMS technology |

| Accuracy | High accuracy, ideal for demanding navigation and control applications, especially with long-term stability | Wide range of accuracy; some high-end MEMS IMUs have achieved comparable accuracy to mid-level FOG gyroscopes, suitable for various applications including military scenarios |

| Drift Rate | Typically features very low drift rate, suitable for long-term continuous operation | Drift rate has significantly improved with technological advancements; some high-end models can rival FOG IMUs |

| Size and Weight | Larger and heavier, suitable for high-precision applications where space and weight are not constraints | Compact and lightweight, ideal for space-constrained applications, widely used in portable devices and military applications |

| Power Consumption | Higher power consumption, suitable for systems where power requirements are not a major concern | Low power consumption, ideal for battery-powered portable devices and long-duration missions |

| Cost | Higher production cost, suited for high-end applications | Varies from low to medium cost, suitable for large-scale consumer, industrial, and military applications |

| Resistance to Interference | Insensitive to electromagnetic interference, ideal for complex electromagnetic environments | Resistance to interference has improved with design and packaging advancements; most MEMS IMUs now offer good resistance to electromagnetic interference |

| Temperature Stability | Excellent temperature stability, suitable for extreme environments | With temperature compensation techniques, many high-end MEMS IMUs perform stably across a wide range of temperatures |

| Applications | High-precision navigation, aerospace, marine, defense, and other high-end applications | Widely used in consumer electronics, drones, military equipment, industrial automation, automotive electronics, and more |

MEMS Inertial Measurement Unit Price

What is the Price Range of MEMS IMU?

The price of MEMS-Based Inertial Measurement Units (IMUs) is mainly determined by the gyroscope accuracy (measured in degrees per hour, °/h), which indicates how precisely the unit can measure angular velocity. The higher the accuracy, the higher the cost. Here’s an overview of the typical pricing based on accuracy levels.

Please note that these price ranges are for reference only. The actual cost of a MEMS IMU can vary depending on factors like customization on additional features.

| Accuracy Range (°/h) | Price Range (per unit) | Typical Applications |

|---|---|---|

| Low Precision (1°/h - 10°/h) | $20 - $1,000 | Consumer electronics, IoT devices, basic motion sensing |

| Mid Precision (0.5°/h - 1°/h) | $1,000 - $5,000 | Drones, robotics, industrial automation, navigation systems |

| High Precision (0.1°/h - 0.5°/h) | $5,000 - $15,000 | Aerospace, automotive navigation, defense, high-end robotics |

A Step-by-Step guide to help you find the right imu

How to Select/Customize the Right

MEMS Inertial Measurement Unit (IMU)

STEP 1

Define Application Requirements

Work with GuideNav’s engineering team to identify the specific application scenarios and performance needs, such as accuracy, drift rate, environmental conditions, and size constraints.

STEP 2

Evaluate Performance Specifications

Key metrics like bias instability, angular random walk (ARW), and dynamic range are crucial. High-precision MEMS IMUs can achieve 0.1°/hr bias instability, suitable for demanding applications like navigation and guidance systems.

STEP 3

Assess Environmental Robustness

Consider the operating conditions. Military and industrial applications need IMUs that can handle high shock, vibration, and temperature extremes, while commercial systems may have less stringent requirements.

STEP 4

Customization Options

Offer customization options for the IMU, including specific sensor configurations, housing materials, and interface types to match your unique requirements.

STEP 5

Prototype and Validation

Develop a prototype based on the selected specifications and perform rigorous testing to validate that the IMU meets all performance criteria and application demands.

STEP 6

Integration and Compatibility

After successful validation, finalize the IMU configuration, and assist you with integration into your system, providing support for any necessary adjustments.

Our Adavantages

Why Choose Guidenav?

Trusted by keyplayers

Our advanced inertial navigation products are trusted by leading organizations in the aerospace, defense, commercial, and industrial sectors from over 25 countries. Our reputation for reliability and precision sets us apart.

Top Performance

Our products deliver top-tier performance with excellent bias stability. Designed for the most demanding applications, our MEMS based IMU can reach bias instability as precise as ≤0.1°/h.

Proven in Harsh Environment

Our solutions are built to withstand extreme conditions, providing consistent performance in harsh environments.

Excellent Performance under Vibrations

Our MEMS and FOG IMU technology excels in high-vibration settings, ensuring accuracy and stability even in the most challenging operational environments.

PLUG & PLAY System

Our systems are designed for easy integration, offering plug-and-play solutions that simplify installation and reduce setup time, allowing you to focus on your mission.

ITAR-FREE

Our products are ITAR-free, offering you the advantage of easier international transactions and fewer regulatory hurdles. Choose GuideNav for seamless global operations.

Our Factory - See to Believe

Why Choose Us

Comprehensive Solutions for All Your Navigation Needs

Commercial Grade Coverage

Bias Stability: >0.2°/h

Solution: MEMS based Gyroscope/IMU/INS

Applications: car navigation, unmanned aerial vehicles, transportation, robotics etc.

Tactical Grade Coverage

Bias Stability: 0.05°/h-0.2°/h

Solution: Fiber Optics and MEMS based Gyroscope/IMU/INS

Applications: armored vehicles operations, anti-aircraft artillery, precision targeting etc.

Navigation Grade Coverage

Bias Stability: ≤0.05°/h

Solution: Fiber Optics & Ring Laser Gyroscope/IMU/INS

Applications: medium and long-range guidance, military aviation, satellites

FAQS

Answers to Your Questions

A MEMS Inertial Measurement Unit (IMU) is a compact device that measures motion parameters, including acceleration and angular velocity, using Micro-Electro-Mechanical Systems (MEMS) technology. Inside, it combines accelerometers and gyroscopes to track orientation and movement in three-dimensional space. The data collected is critical for applications requiring precise motion tracking.

GuideNav’s MEMS IMUs are ideal for a wide range of applications that demand high precision and reliability. These include aerospace, defense, autonomous vehicles, robotics, industrial systems, deep-sea exploration, and pipeline positioning. Our IMUs excel in harsh environments where stability and accuracy are critical. Additionally, we offer customizable solutions with varying levels of precision to meet the unique demands of different industries. Contact us for a tailored solution that fits your specific application requirements.

Important metrics include bias stability, angular random walk, bandwidth, and temperature compensation. We provide various models with different performance specifications, ensuring each application’s unique needs are met. Customization is available to align specifications with exact project requirements—contact us for details.

GuideNav’s MEMS IMUs undergo comprehensive calibration, including dynamic and temperature compensation, to ensure stability in all environments. Our models also incorporate advanced error correction and data integrity algorithms. For applications requiring different accuracy levels, we offer tailored precision solutions.

GuideNav offers a wide range of customization options, including specific interface choices (e.g., RS232, RS422), adjustable data output rates, operating range and even housing material variations. We can modify performance characteristics to better suit your application’s demands. Contact us to explore a custom solution for your project.

MEMS IMUs provide reliable motion tracking, stability, and resilience in extreme conditions, critical for applications like missile guidance, aircraft navigation, and unmanned systems. GuideNav’s solutions cover varying levels of precision to accommodate diverse mission profiles within these sectors.

Our MEMS IMUs are built for reliability in extreme environments, withstanding temperatures from -40°C to +85°C and offering high resistance to vibration, shock, and humidity. We also provide customizable environmental specifications for applications with unique operational demands.

MEMS IMUs use micro-scale sensors, which make them smaller, lighter, and often more power-efficient than traditional IMUs. While traditional IMUs may provide higher precision in some cases, GuideNav offers various MEMS models that balance cost-effectiveness with high performance. Customization allows us to match the precision you need.

Certainly! We have a wealth of informative articles on our blog that delve into the fundamentals of MEMS IMUs. You can explore topics like:

- How Accurate is the Inertial Measurement Unit (IMU)?

- What is a MEMS IMU?

- The Ultimate Guide to Inertial Measurement Unit (IMU)

These resources will help you better understand the technology, accuracy, and applications of MEMS IMUs. Feel free to explore and contact us for any further questions!