Navigation projects face one universal problem: systems must deliver accuracy even when GNSS is jammed, vibration is high, or conditions are extreme. Choosing the wrong sensor here is costly—low-grade gyroscopes drift quickly, causing UAVs to lose course or vehicles to fail missions. That’s the hidden risk many teams overlook.

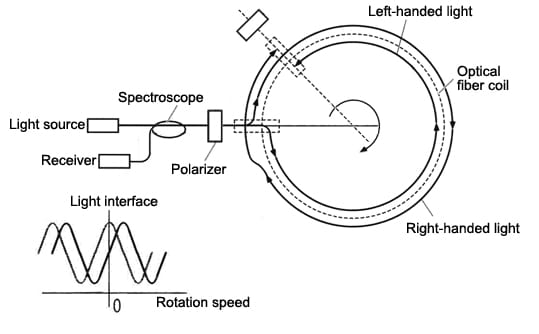

The answer is Fiber Optic Gyroscopes (FOG). With stability, reliability, and resilience far beyond MEMS or mechanical sensors, FOGs are trusted in defense, aerospace, and industrial platforms. But not all FOGs are the same. To succeed, you need one that not only looks good on paper but also integrates smoothly, performs in the field, and comes with long-term support.

Selecting the wrong Fiber Optic Gyroscope (FOG) can delay projects and raise costs. Smart buyers look beyond the datasheet-choosing a FOG that integrates smoothly, performs consistently, and comes with guaranteed long-term service and delivery assurance.

When choosing a Fiber Optic Gyroscope, it’s tempting to focus only on numbers like bias stability or ARW. While these specifications matter, they don’t guarantee success in the field. What truly determines project outcomes is whether the FOG can integrate smoothly into your system, maintain accuracy under real-world stress, and be supported over its entire lifecycle. In practice, there are several important factors beyond the datasheet that can make or break your project.

Table of contents

Integration: Will It Work With Your System?

A Fiber Optic Gyroscope may look impressive on paper, but the real challenge begins when it’s connected to a navigation computer or mission system. Integration problems are common—interfaces don’t match, documentation is thin, or support is slow. Even short delays can disrupt schedules and add hidden costs.

One UAV integrator reported losing nearly a month rewriting drivers because the FOG lacked support for their CAN protocol. The takeaway: great specs mean little if the sensor cannot “speak the language” of your system.

Key points to check before choosing:

- Support for standard interfaces like RS422, CAN bus, or Ethernet

- Availability of SDKs, APIs, and wiring guides

- Direct engineering support during first integration trials

A FOG that integrates seamlessly reduces risk, saves time, and accelerates deployment.

What Interfaces Ensure Smooth Integration?

Even the most accurate FOG becomes a burden if it cannot “talk” to your system. Interfaces define how quickly and reliably data flows into your navigation computer, and the wrong choice can mean extra converters, higher latency, and more points of failure.

Common options include:

- Ethernet→ High bandwidth, ideal for airborne surveillance or naval systems.

- RS422→ Robust, noise-resistant, widely used in industrial automation.

- CAN bus→ Standard in defense vehicles, perfect for distributed control.

- Custom interfaces→ Flexible but may increase cost and integration time.

Real-world example: A land vehicle program in Europe chose a FOG with Ethernet output, only to discover late in the project that their control unit required CAN. The extra interface board worked, but added weight, power consumption, and complexity.

Tip: Always choose the interface that matches your platform from day one. Smooth integration reduces engineering overhead and accelerates deployment.

How Do Size, Weight, and Power (SWaP) Shape Your Choice?

In navigation projects, the best FOG is not always the smallest or the most powerful—it’s the one that fits your platform’s SWaP envelope. A UAV designer may value every gram saved, while a naval system engineer may prioritize ruggedness over weight.

| Platform | SWaP Priority | Practical Guidance |

|---|---|---|

| UAVs | Lightweight & low power | Compact FOG IMUs under 500 g with minimal power draw |

| Land vehicles | Balanced approach | Medium-sized FOGs offering shock resistance without excess power demand |

| Naval systems | Ruggedness over weight | Heavier housings with reinforced protection against vibration, salt, and humidity |

A defense robotics company once selected an ultra-compact FOG for a tracked UGV. While it saved weight, the smaller housing amplified vibration issues, forcing them to switch to a mid-sized unit. The heavier option proved far more reliable in real deployments.

Lesson learned: SWaP is not just a design constraint; it’s a performance factor. Always balance size, weight, and power with long-term mission requirements.

Does It Perform in Real-World Conditions?

A FOG that looks strong in laboratory tests may reveal weaknesses once deployed in the field. UAVs encounter turbulence, ground vehicles operate under constant shock and vibration, and naval systems must endure humidity, salt, and rapid temperature shifts. Numbers such as 0.05 °/h bias stability or 0.003 °/√h ARW only matter if the sensor can consistently hold them under these conditions.

In practice, two FOGs with similar datasheet values can behave very differently once exposed to extreme environments. One unit might maintain stability across the full temperature range, while another may show drift when vibration levels rise. That’s why experienced teams never rely solely on laboratory figures.

Key takeaway: Always look for field test data and proven performance records. Real-world validation shows whether a FOG can maintain accuracy where it matters most—during missions, not just in controlled test environments.

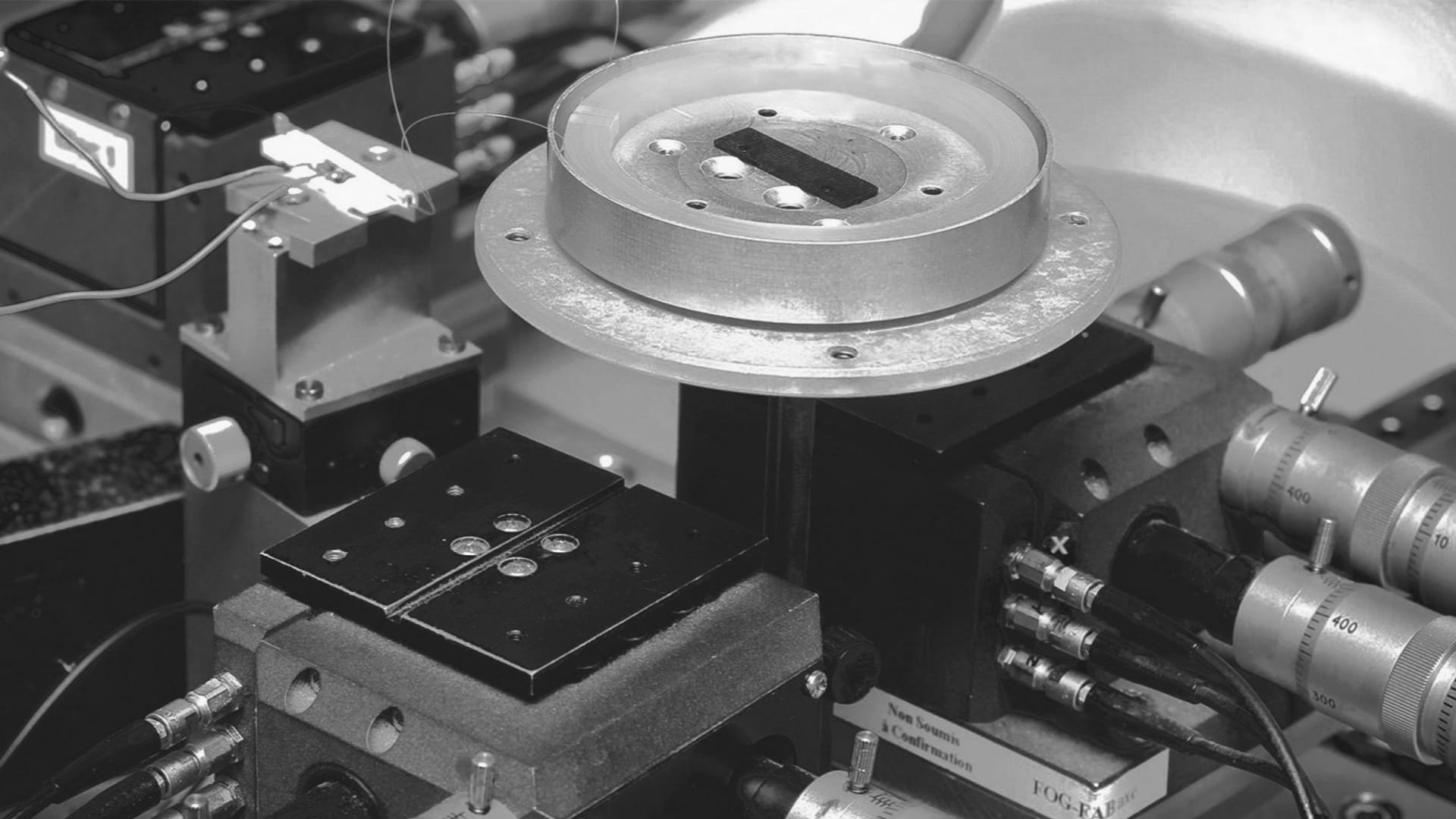

Is the FOG Field-Proven or Still a Prototype?

A datasheet can look flawless, but if the product has never left the lab, it carries real risk. Many teams underestimate the importance of mission heritage—knowing that a FOG has already survived the same kind of environment where you plan to use it.

Case in point: A European defense integrator adopted a new FOG advertised with excellent stability. During vibration testing, the unit failed repeatedly because it had never been validated outside a controlled lab. The result was a forced supplier switch and a six-month delay.

How to confirm real-world maturity:

- Ask if the FOG has been deployed in UAVs, land vehicles, or naval systems.

- Request documented mission heritageor customer references.

- Check for certifications such as MIL-STD-810.

- Verify whether the supplier has long-term usersin defense or industry.

A field-proven FOG isn’t just about reliability—it’s about de-risking your project schedule and budget.

Can the Supply Chain Keep Up With Your Schedule?

A Fiber Optic Gyroscope with excellent specifications won’t help if it arrives months late. In defense and industrial projects, delays in sensor delivery often cascade into missed deadlines, contractual penalties, and lost opportunities.

Think of procurement in three phases:

Prototype → Small Batch → Mass Production

- Prototype samplesshould be available in 2–4 weeks for evaluation.

- Small batch orders (10–50 units)should ship within 1–3 months.

- Mass productionmust be scalable without altering specs or quality.

Example: An aerospace integrator reported waiting almost nine months for critical sensors, forcing them to redesign part of their system around an alternative supplier. The technical specs weren’t the issue—the bottleneck was supply.

Key checks before committing:

- Does the supplier maintain dynamic stock?

- Are lead times transparent and realistic?

- Can logistics partners support your region?

A FOG that meets your deadlines is just as important as one that meets your technical requirements.

What Kind of After-Sales Support Will You Get?

Buying the sensor is only the beginning. A FOG typically serves in the field for five to ten years, which means after-sales support can determine the real value of your investment.

Maintenance & Recalibration

Over time, sensors require recalibration to maintain accuracy. Reliable suppliers provide scheduled services and accessible regional centers.

Firmware & Software Updates

System requirements change. Access to firmware upgrades ensures the FOG can adapt without replacing hardware.

Technical Assistance

Responsive engineering support shortens troubleshooting time and prevents costly downtime.

Bottom line: Support is not optional—it is part of the product. Choosing a FOG with strong service ensures reliability throughout its lifecycle.

Is the FOG Export-Friendly and Globally Serviceable?

Export restrictions can quietly derail international projects. A sensor that looks perfect on paper may become unusable if regulations block its shipment. For defense, aerospace, and cross-border industrial programs, choosing the right FOG often means choosing one that is ITAR-free and supported worldwide.

| Factor | Restricted FOG (ITAR/EAR) | Export-Friendly FOG (ITAR-Free) |

|---|---|---|

| Procurement timeline | Long approval cycles, months lost | Faster, straightforward delivery |

| Global collaboration | Limited, often country-specific | Open to multinational programs |

| Support access | Restricted service locations | Wider network of service partners |

| Flexibility | Project scope may shrink | Freer system design and integration |

Key takeaway: If your project involves international teams or global supply chains, export-friendly FOGs ensure smoother procurement, faster deployment, and uninterrupted service.

Why GuideNav Is the Right Partner for FOG Solutions

Choosing the right Fiber Optic Gyroscope is about more than specifications—it’s about partnering with a supplier who ensures smooth integration, proven performance, and long-term support. That’s exactly where GuideNav makes the difference.

- Broad Capability– A complete FOG portfolio designed to meet diverse defense, aerospace, and industrial needs.

- Proven Experience– With over 15 years in the field, GuideNav products have been trusted in demanding real-world projects worldwide.

- Tailored Solutions– Flexible design, calibration, and interface support to ensure every sensor fits your mission requirements.

- Global Support– Export-friendly solutions, dynamic stock, and responsive service teams that keep your programs on schedule.

Bottom line: GuideNav is not just a sensor vendor—it’s a navigation partner committed to supporting your mission from prototype to full deployment.