Why an IMU Cannot Measure Angles Directly?

INS dead-reckoning keeps agricultural robots on track when GNSS signals fail. With stable gyroscope bias, low drift, and sensor fusion using wheel odometry and gravity alignment, autonomous tractors can maintain row accuracy even under canopy, inside barns, or near metallic structures.

Handling GNSS Outages in Agricultural Robots: INS Dead-Reckoning Strategies

INS dead-reckoning keeps agricultural robots on track when GNSS signals fail. With stable gyroscope bias, low drift, and sensor fusion using wheel odometry and gravity alignment, autonomous tractors can maintain row accuracy even under canopy, inside barns, or near metallic structures.

How to Handle IMU Gyroscope Temperature Drift?

IMU temperature drift is a major cause of accuracy degradation in inertial systems. Through hardware optimization, full-range thermal calibration, and online compensation, engineers can significantly reduce drift and ensure stable attitude performance.

How Gyroscopes and Accelerometers Shape IMU Performance

A stable IMU relies on fusing gyroscope and accelerometer data. Gyroscopes drift, accelerometers are noisy, and a complementary filter blends both to deliver reliable, lightweight real-time attitude estimation.

Quartz Accelerometer vs. MEMS Accelerometer

Quartz Accelerometers provide superior long-term precision and stability, while MEMS Accelerometers deliver compact, durable, and cost-effective performance. The right choice depends on your project’s accuracy requirements, budget, and environmental conditions.

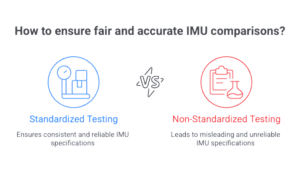

Why Testing Conditions Define the True Meaning of IMU Specifications

IMU testing conditions determine how realistic and reliable IMU specifications truly are. Temperature, vibration, duration, and filtering all shape what the datasheet claims — and what the sensor actually delivers.