Selecting the right Inertial Measurement Unit (IMU) is critical for ensuring stable and high-precision navigation and control. The Honeywell HG1930 stands as one of the most recognized tactical-grade MEMS IMUs, widely adopted in UAVs, guided systems, and industrial automation. Built for reliability and compactness, it delivers proven performance across harsh environments; however, engineers should also consider its integration flexibility, export compliance, and overall cost when comparing it with newer MEMS alternatives.

The Honeywell HG1930 is a compact, tactical-grade MEMS IMU offering reliable performance and rugged design for UAVs, robotics, and defense systems. It delivers stable accuracy in harsh environments but comes with higher cost and export limitations.

The Honeywell HG1930 continues to serve as a dependable choice in many tactical-grade navigation systems. Its proven durability, precision, and adaptability make it a trusted solution for engineers seeking consistent performance in challenging operating conditions.

Table of contents

What are the advantages of the HG1930 IMU?

1. Proven Reliability and Design Heritage

Honeywell designs, develops, and manufactures all MEMS sensors used in HG1930.

This vertical integration ensures tight control over performance, calibration, and long-term reliability. The unit has been field-proven across UAVs, munitions, and industrial platforms—earning a solid reputation in tactical applications.

2. Compact and Lightweight Form Factor

With a volume of only 5 in³ and a weight below 0.35 lb (160 g), HG1930 provides excellent performance-to-size ratio.

Such compactness makes it ideal for SWaP-constrained platforms like small drones, handheld devices, or precision-guided systems.

3. Strong Environmental Endurance

The HG1930 operates over a wide temperature range of −54 °C to +85 °C and features an internal isolation system to minimize the effect of vibration and shock.

Its rugged aluminum housing and solid-state electronics enable long-term durability even in severe mechanical environments.

4. Configurable Performance Grades

Honeywell offers three off-the-shelf configurations—CA50, BA50, and AA50—allowing users to balance cost, precision, and operational needs.

Bias stability ranges from 0.25 °/h to 0.4 °/h, while accelerometer bias can be as low as 0.02 mg, which covers most tactical-level navigation and stabilization requirements.

5. Fast Start-Up and Standard Interfaces

The HG1930 achieves < 350 ms start-time, ensuring rapid system initialization—a critical advantage in missiles or UAVs requiring quick deployment.

It also supports RS-422, SDLC, and custom asynchronous protocols, making integration straightforward with both legacy and modern flight-control systems.

6. Long Storage and Operational Life

Honeywell guarantees a 20-year storage life without mandatory overhaul—demonstrating its design maturity and reliability for long-term defense and aerospace programs.

What are the disadvantages of the HG1930 IMU?

1. Temperature-Dependent Accuracy

Even though the unit compensates for temperature, residual drift increases at extremes of its −54 °C to +85 °C range.

Applications requiring stable navigation in highly dynamic or thermal environments (e.g., deep subsea or desert operations) may experience slight bias fluctuations.

2. Proprietary Interface and Documentation

Unlike some open-architecture IMUs, the HG1930 uses Honeywell-specific interface protocols and message structures.

This can complicate integration for small developers or research users who prefer open communication formats like NMEA or ASCII.

3. Price and Export Restrictions

As a controlled tactical-grade IMU (ECCN 7A003.d.1), HG1930 is subject to U.S. export compliance, which can limit availability to certain regions.

Additionally, Honeywell pricing tends to be on the higher end compared with newer MEMS competitors providing similar tactical-level performance.

4. No Integrated GNSS or Kalman Filtering

The HG1930 is a pure IMU, meaning it requires external navigation processors to deliver orientation or position estimates.

It lacks embedded fusion algorithms, which modern INS modules increasingly include to simplify system-level integration.

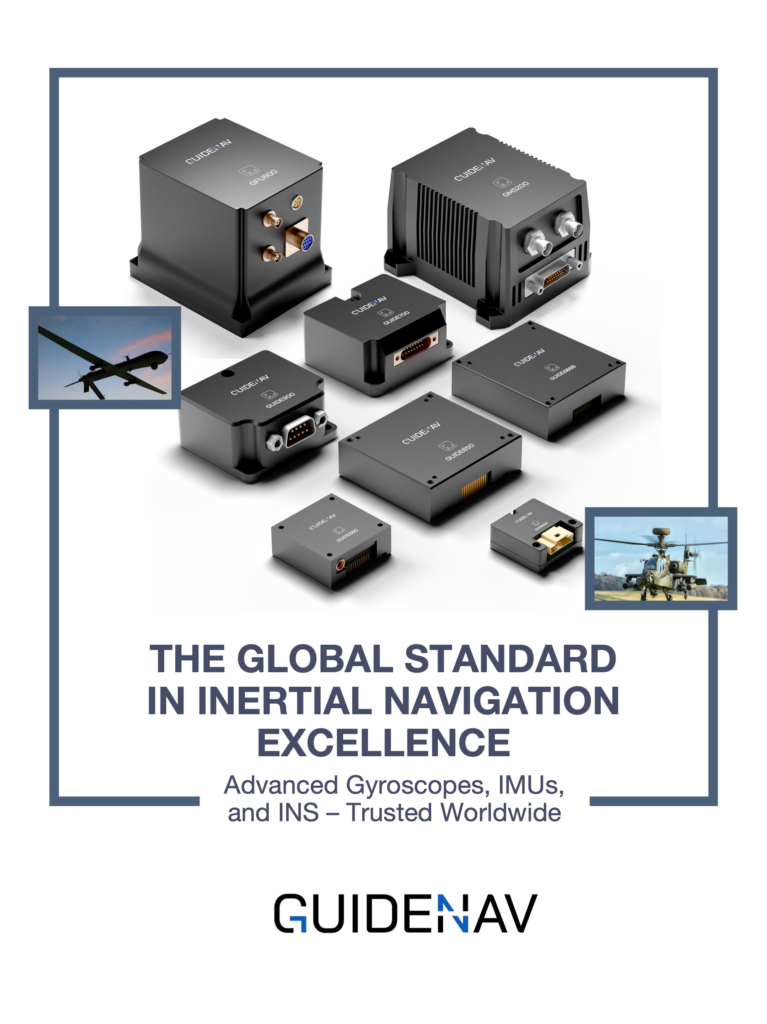

Alternative Solution: GuideNav GUIDE703 IMU

For users seeking a non-ITAR, cost-effective alternative to the HG1930 while maintaining tactical-grade precision, the GuideNav GUIDE703 MEMS IMU presents a compelling option .

The GUIDE703 is a tactical-grade MEMS IMU integrating high-performance triaxial gyroscopes and accelerometers with advanced error compensation for temperature, misalignment, and nonlinearity.

It delivers 1 °/h gyro bias instability, 0.2 mg accelerometer bias, and supports RS-422 interface with a high 900 Hz data rate.

Weighing just 120 g and operating reliably from −45 °C to +85 °C, the GUIDE703 is engineered for autonomous systems, UAVs, AGVs, and mobile satcom platforms requiring high stability under shock and vibration up to 2000 g / 6 grms.

Why GUIDE703 Is a Practical Replacement

- Comparable tactical-grade stability(1 °/h gyro, 0.2 mg accel) at lower cost.

- Fully open RS-422 communicationprotocol for fast integration.

- Wide temperature and vibration endurancesimilar to HG1930.

- Compact form factor(65 × 50.8 × 35.6 mm) suitable for retrofit or OEM integration.

- No export restrictions, enabling smooth international supply.

In short, while Honeywell’s HG1930 remains a benchmark of legacy performance, GuideNav’s GUIDE703 offers a modern, ITAR-free MEMS alternative — optimized for tactical navigation, industrial automation, and unmanned systems where precision meets flexibility.