Selecting the right accelerometer isn’t just about comparing numbers on a datasheet—it’s about matching precision, cost, and reliability to your system’s mission profile. Yet, many buyers face the same dilemma: should they choose a Quartz Accelerometer for accuracy or a MEMS Accelerometer for practicality?

Quartz Accelerometers provide superior long-term precision and stability, while MEMS Accelerometers deliver compact, durable, and cost-effective performance. The right choice depends on your project’s accuracy requirements, budget, and environmental conditions.

As defense, aerospace, and industrial systems become increasingly performance-driven, the procurement decision between Quartz and MEMS Accelerometers has become a key technical and financial consideration. This guide compares both technologies from a buyer’s point of view—highlighting differences in principle, performance, reliability, and cost-effectiveness.

Table of contents

What Is a Quartz Accelerometer?

A Quartz Accelerometer uses a piezoelectric quartz crystal as its sensing element. When acceleration is applied, the crystal generates a proportional charge, offering highly stable and repeatable performance.

Key advantages include:

- Outstanding bias stability(10–100 µg range)

- Low temperature sensitivity

- Minimal long-term drift

These features make quartz accelerometers ideal for navigation-grade IMUs, missile guidance systems, marine surveying, and defense-grade platforms requiring ultra-precise measurements.

What Is a MEMS Accelerometer?

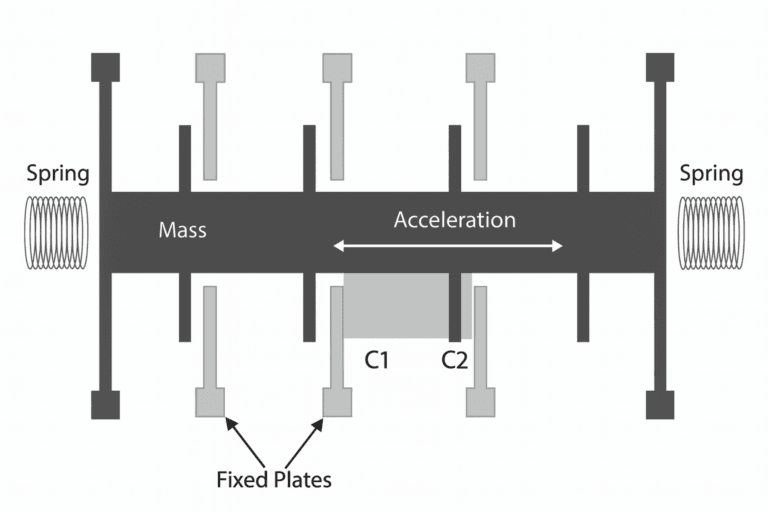

A MEMS Accelerometer (Micro-Electro-Mechanical System) detects acceleration using micro-machined proof masses and capacitive sensing. Its strength lies in miniaturization and integration.

Core benefits include:

- Compact size and low power consumption

- High shock resistance and low cost

- Ease of integration with MEMS gyros and magnetometers

Modern MEMS Accelerometers now achieve sub-100 µg bias stability, enabling reliable use in UAVs, autonomous vehicles, and industrial robots—applications once dominated by quartz-based sensors.

How Do They Differ in Core Performance?

When evaluating performance, procurement engineers should focus on measurable parameters such as bias stability, noise density, temperature coefficient, and shock tolerance. These indicators determine whether precision, robustness, or cost efficiency takes priority in your design.

| Parameter | Quartz Accelerometer | MEMS Accelerometer |

|---|---|---|

| Bias Stability | 10–100 µg | 50–500 µg |

| Noise Density | 10–50 µg/√Hz | 50–500 µg/√Hz |

| Temperature Coefficient | Very low | Moderate |

| Shock Tolerance | Limited (~1,000 g) | Excellent (up to 20,000 g) |

| Size & Power | Larger, higher power | Compact, low power |

| Cost | High | Low to moderate |

Interpretation:

If your project demands absolute precision and long-term stability, quartz is the better option. For SWaP-limited (size, weight, and power) or cost-sensitive systems, a MEMS Accelerometer delivers the best balance.

Which Offers Better Environmental Stability?

Quartz accelerometers are known for their exceptional environmental stability, maintaining precise output across a wide temperature range from −55 °C to +85 °C. They demonstrate minimal bias drift under thermal stress, vibration, and long-term operation, which makes them a preferred choice for navigation and defense-grade systems.

In contrast, a MEMS Accelerometer, although significantly improved in recent years, may still show small bias or scale factor variations under extreme conditions. However, with modern temperature-compensated circuitry and improved fabrication processes, today’s MEMS Accelerometers achieve excellent repeatability for UAVs, automotive, and industrial applications.

Quartz devices are naturally immune to humidity and aging effects, while MEMS types often require hermetic packaging to maintain long-term stability. For systems exposed to wide environmental variation, quartz remains unmatched in precision, but MEMS continues to close the gap through better thermal calibration and robust mechanical design.

What About Reliability and Lifetime?

Quartz accelerometers have a demonstrated operational lifespan exceeding 15 years, performing reliably in missile guidance, marine navigation, and geophysical instruments with minimal recalibration. In comparison, a MEMS Accelerometer generally offers a lifespan of 5–10 years, depending on its exposure to shock, vibration, and temperature cycling.

Despite that difference, MEMS Accelerometers provide outstanding mechanical resilience, capable of withstanding shocks up to 20,000 g—far beyond quartz-based designs. This characteristic makes them ideal for highly dynamic or impact-prone environments such as drones, autonomous vehicles, and robotics.

Long-term reliability depends on the balance between environmental endurance and structural toughness. Quartz ensures consistent performance over extended missions, while MEMS provides robustness and ease of replacement—qualities that make it practical for compact, frequently updated systems.

Which Is More Cost-Effective?

A high-end quartz accelerometer can cost up to ten times more than a MEMS Accelerometer, but cost-effectiveness depends on more than just the unit price. Calibration frequency, replacement intervals, and lifecycle stability all contribute to the overall value of a sensing solution.

For long-duration or high-precision programs, quartz accelerometers offer superior lifecycle performance through unmatched bias stability and long-term drift control. On the other hand, MEMS Accelerometers are ideal for high-volume, SWaP-constrained, or short-lifecycle applications, where affordability and integration efficiency are crucial.

Because MEMS fabrication follows semiconductor-scale production, availability and lead time are generally more predictable. Quartz sensors, being individually assembled and calibrated, may take longer to deliver but provide exceptional precision for mission-critical aerospace or defense applications. In most modern designs, MEMS Accelerometers achieve the best trade-off between accuracy, robustness, and cost, making them the preferred solution for next-generation navigation systems.

How to Decide Based on Application?

| Application | Recommended Type | Reason |

|---|---|---|

| Missile / Defense Navigation | Quartz | High precision and stability |

| UAV / Drone Autopilot | MEMS Accelerometer | Lightweight and cost-effective |

| Surveying Instruments | Quartz | Low drift over long durations |

| Industrial Robots | MEMS Accelerometer | Compact and reliable |

| Marine Gyrocompass | Quartz | Excellent temperature stability |

What Trends Are Shaping the Future?

The performance gap is narrowing. Advanced MEMS Accelerometers now integrate digital temperature compensation, closed-loop designs, and self-calibration functions, delivering near-quartz performance at a fraction of the cost.

Meanwhile, quartz remains the gold standard for precision navigation, still unmatched in strategic-grade applications. Hybrid IMUs combining MEMS gyros and quartz accelerometers are emerging as an optimal solution, blending long-term stability with compact design.

What Should Procurement Engineers Focus On?

Key evaluation criteria for decision-makers include:

- Bias and scale-factor stabilityacross temperature

- Noise density and dynamic range

- Operating environment and vibration exposure

- Supplier reliability and calibration services

- Export control compliance (ITAR/EAR restrictions)

A well-informed selection minimizes over-specification and cost overruns, ensuring the chosen sensor meets both technical and logistical requirements.

Final Thoughts: Finding the Right Balance

Both quartz and MEMS technologies have proven their value in precision sensing.

- Choose Quartz Accelerometersfor defense, navigation, and long-term stability.

- Choose MEMS Accelerometersfor lightweight, scalable, and cost-sensitive applications.

At GuideNav, we design and manufacture both MEMS and hybrid IMUs that bridge the gap between tactical precision and commercial practicality. Each product is built to deliver the reliability, stability, and accuracy demanded by professional applications—validated through rigorous testing, environmental calibration, and long-term performance verification to ensure dependable results in any mission environment.