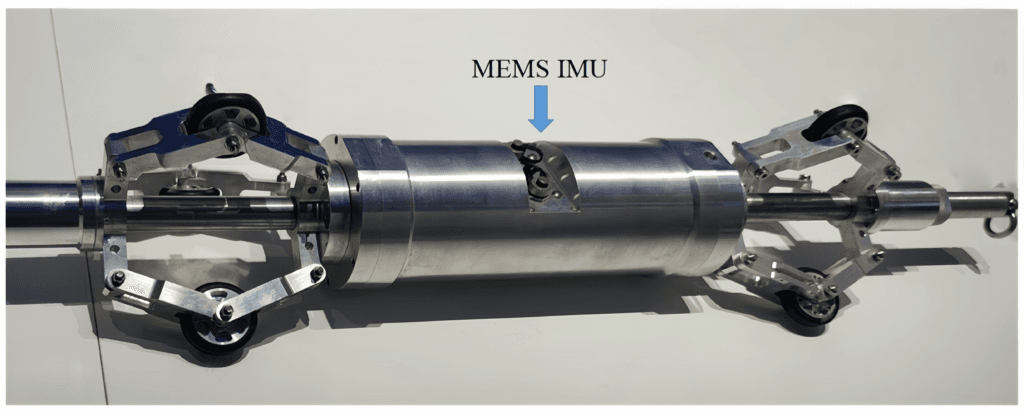

Underground and subsea pipelines are difficult to inspect because GPS signals, light, and magnetic references all disappear inside. Traditional sensors like cameras and encoders lose accuracy on slippery or curved surfaces, making defect localization unreliable. In such GNSS-denied environments, MEMS Inertial Measurement Units (IMUs) provide a self-contained navigation solution. Compact, low-power, and vibration-resistant, these MEMS-based inertial sensors enable pipeline inspection robots to maintain stable orientation, measure precise motion, and map defects accurately-even hundreds of meters below the surface.

MEMS IMUs deliver precise inertial navigation for pipeline inspection robots operating in GNSS-denied environments. By providing stable attitude, velocity, and position data, they ensure reliable defect mapping, smooth trajectory control, and continuous operation in confined underground or subsea pipelines.

Inside a pipeline, where GNSS and visual cues vanish, navigation depends entirely on MEMS IMUs. These compact inertial sensors capture angular rate and acceleration to build a continuous motion profile. For a pipeline inspection robot, accurate inertial navigation means knowing its exact position, attitude, and velocity-the foundation for reliable defect detection and mapping.

Table of contents

The Navigation Challenge Inside GNSS-Denied Pipelines

For a pipeline inspection robot, navigation is the hardest problem. Deep inside metallic pipelines, GNSS signals are completely blocked, and even magnetic sensors lose reliability. The only way to maintain accurate motion tracking is through inertial navigation powered by a MEMS IMU. By continuously measuring angular rate and linear acceleration, the IMU helps the robot compute its real-time orientation, velocity, and position. Any bias instability or integration drift can cause major mapping errors — which is why high-performance GuideNav MEMS IMUs are essential for precise underground inspection in GNSS-denied environments.

Why MEMS IMU Technology Fits Pipeline Inspection Robots Perfectly

Compact. Rugged. Precise.

Inside a narrow steel pipeline, every millimeter and every watt matters.

That’s where the MEMS IMU proves irreplaceable.

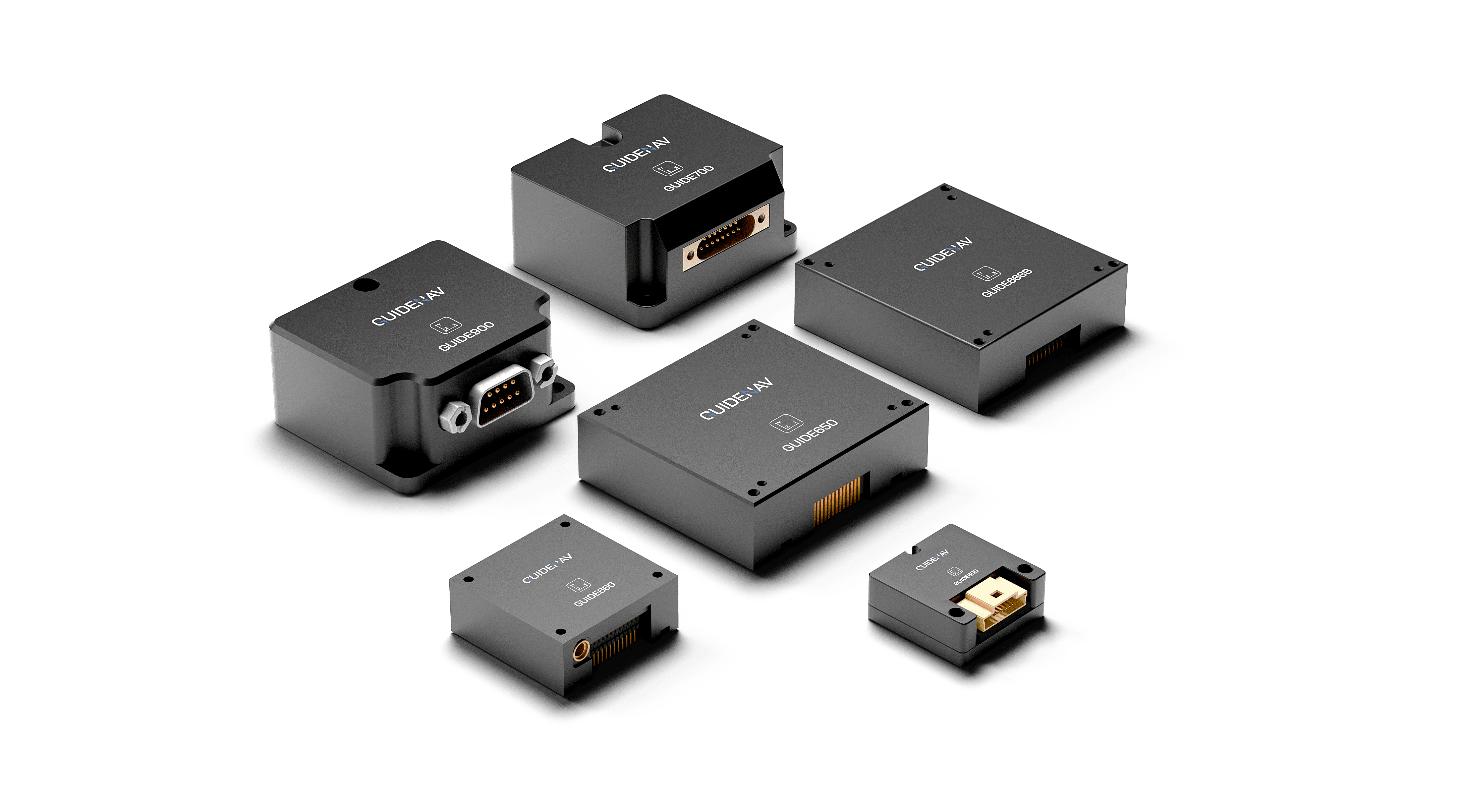

- Compact & Lightweight:Easily integrated into small-diameter pipeline inspection robots where space is limited.

- Low Power & Efficient:Supports long-endurance missions without overloading power systems.

- Vibration-Resistant:Maintains stable inertial navigation even under 20 g RMS vibration.

- Temperature-Tolerant:Operates reliably across –40 °C to +85 °C.

Unlike bulky FOG units, a MEMS-based inertial system delivers high-precision motion data in a miniature form factor — ideal for GNSS-denied underground environments.

From Raw Motion Data to Precise Position Mapping

In a GNSS-denied pipeline, every movement of a pipeline inspection robot must be self-measured.

A MEMS IMU transforms raw motion signals into meaningful inertial navigation data through a precise computational workflow:

Step 1 Sensing Motion

High-grade MEMS gyroscopes measure angular velocity while MEMS accelerometers detect linear acceleration.

Together they form the foundation of the robot’s internal motion reference.

Step 2 Integration & Computation

The onboard processor integrates IMU data to estimate attitude, velocity, and position in real time.

This is the core of dead-reckoning navigation, which allows continuous tracking even without GPS.

Step 3 Defect Localization

When cameras or ultrasonic probes identify corrosion or cracks, the GuideNav MEMS IMU provides accurate spatial coordinates.

This enables engineers to link every defect to its exact location along the pipeline.

Step 4 Map Generation

The combined data feed builds a high-resolution pipeline inspection map, aligning structural integrity reports with physical coordinates — a process made possible only through inertial navigation powered by MEMS IMUs.

In short: From raw acceleration to precise mapping, every stage of the process relies on the accuracy and bias stability of a GuideNav MEMS IMU operating in challenging underground or subsea environments.

The Role of Bias Stability in Underground Navigation

Why Bias Stability Matters

In a pipeline inspection robot, every degree of drift matters.

Inside long GNSS-denied pipelines, even a small IMU bias can accumulate into large positional errors after hours of travel.

For example, a 1°/h gyro bias may cause the robot’s calculated position to deviate by several meters — enough to mislabel a corrosion site.

What Causes Bias Drift

Bias instability in a MEMS IMU typically comes from:

- Temperature fluctuation within the pipeline

- Long-term vibration and mechanical stress

- Manufacturing variation and aging of MEMS elements

These factors gradually distort the inertial navigation output, causing inaccurate mapping and false positional data.

How Industrial MEMS IMUs Solve It

High-grade industrial sensors like GuideNav MEMS IMUs use:

- Closed-loop digital compensation

- Multi-temperature calibration

- Real-time bias estimation via Kalman filtering

This ensures excellent bias stability, allowing a pipeline inspection robot to travel several kilometers with minimal drift.

Such performance defines the difference between consumer-grade sensors and industrial MEMS inertial navigation systems used for precision infrastructure inspection.

Fighting Vibration — Mechanical and Algorithmic Compensation

Inside active pipelines, pumps and flow turbulence create constant vibration that disturbs inertial navigation.

Low-grade MEMS IMUs often misread these oscillations as real motion, causing drift and unstable attitude in pipeline inspection robots.

GuideNav MEMS IMUs solve this with micro-damped mechanical design, digital filtering, and adaptive Kalman algorithms that remove vibration-induced bias in real time.

Temperature Stability and Thermal Calibration

Pipelines often span environments from freezing soil to hot compressor zones, where temperature changes can distort MEMS IMU readings.

Unstable temperature affects bias and scale factor, leading to navigation drift in pipeline inspection robots.

To counter this, GuideNav MEMS IMUs use multi-point temperature calibration and digital thermal compensation models, ensuring bias stability across –40 °C to +85 °C.

This guarantees consistent inertial navigation accuracy in long-duration missions, even under severe environmental variation — a critical advantage for GNSS-denied underground or subsea operations.

Sensor Fusion — The Key to Long-Term Accuracy

Even the most stable MEMS IMU accumulates drift over time.

To maintain accuracy in pipeline inspection robots, raw inertial navigation data must be fused with wheel encoders, pressure sensors, or ultrasonic range finders.

Using advanced Kalman filtering or error-state fusion, GuideNav MEMS IMUs combine these signals to continuously estimate and correct bias.

This multi-sensor approach minimizes cumulative error, ensuring precise trajectory and defect localization over long distances.

In GNSS-denied environments, such intelligent sensor fusion is what turns raw inertial data into reliable, real-world navigation performance.

Unattended drift does not cause an immediate malfunction, but it silently erodes precision over time. Routine factory recalibration keeps the FOG IMU within its original performance limits.

Engineering Considerations for MEMS IMU Integration

Even the most accurate MEMS IMU can lose performance if poorly installed.

In a pipeline inspection robot, precise mechanical alignment and rigid mounting are vital for reliable inertial navigation.

Misalignment between the IMU axes and the robot’s body frame can cause scale-factor and cross-axis errors that no software can fully correct.

GuideNav MEMS IMUs are factory-calibrated to within 200 ppm orthogonality and provide RS-422 or CAN interfaces for easy integration with industrial controllers.

Proper installation ensures consistent bias stability and accurate motion tracking, enabling dependable navigation in GNSS-denied underground pipelines.

Future Outlook — MEMS IMU as the Brain of Autonomous Pipeline Robots

Next-generation pipeline inspection robots are shifting toward full autonomy.

At their core, the MEMS IMU provides continuous inertial navigation in GNSS-denied environments, enabling precise motion control and defect mapping.

Future systems will integrate GuideNav MEMS IMUs with AI analytics for smarter, self-correcting navigation — making the IMU not just a sensor, but the intelligent core of every autonomous underground robot.