High-precision MEMS IMUs often underperform after integration. Drift, misalignment, and environmental factors quietly erode accuracy—until field failures appear. Follow four rules—rigid alignment, controlled environment, periodic calibration, and disciplined operation—to preserve true precision.

High-precision MEMS IMUs deliver unmatched motion sensing performance — but only if used correctly. This reveals four critical usage mistakes that often cause accuracy loss, and how to prevent them in real-world integration.

High-precision MEMS IMUs are the backbone of modern navigation — from drones to autonomous vehicles. Yet even premium sensors can’t perform if mishandled. This guide exposes the hidden traps that quietly ruin accuracy and shows how integrators can prevent them.

Table of contents

Installation: The Starting Point of Every High-Precision MEMS IMU

Mount It Rigidly — Not Softly

A MEMS IMU reports only its own motion, so it must move exactly as the platform moves. For reliable results, fasten the unit directly to a rigid structure using metal or carbon-fiber brackets. Avoid rubber pads or other soft materials that flex or absorb vibration—they break the mechanical link and corrupt the sensor data.

If vibration isolation is unavoidable, design it carefully and verify that the damping characteristics do not distort the IMU’s output frequency or phase response.

Align the Axes Perfectly

Even a small angular offset can create major position errors. When a high-precision MEMS IMU is misaligned by just one degree, the resulting drift can reach kilometers after extended operation. Always align the IMU’s axes with the vehicle’s reference frame, or apply precise alignment calibration after installation.

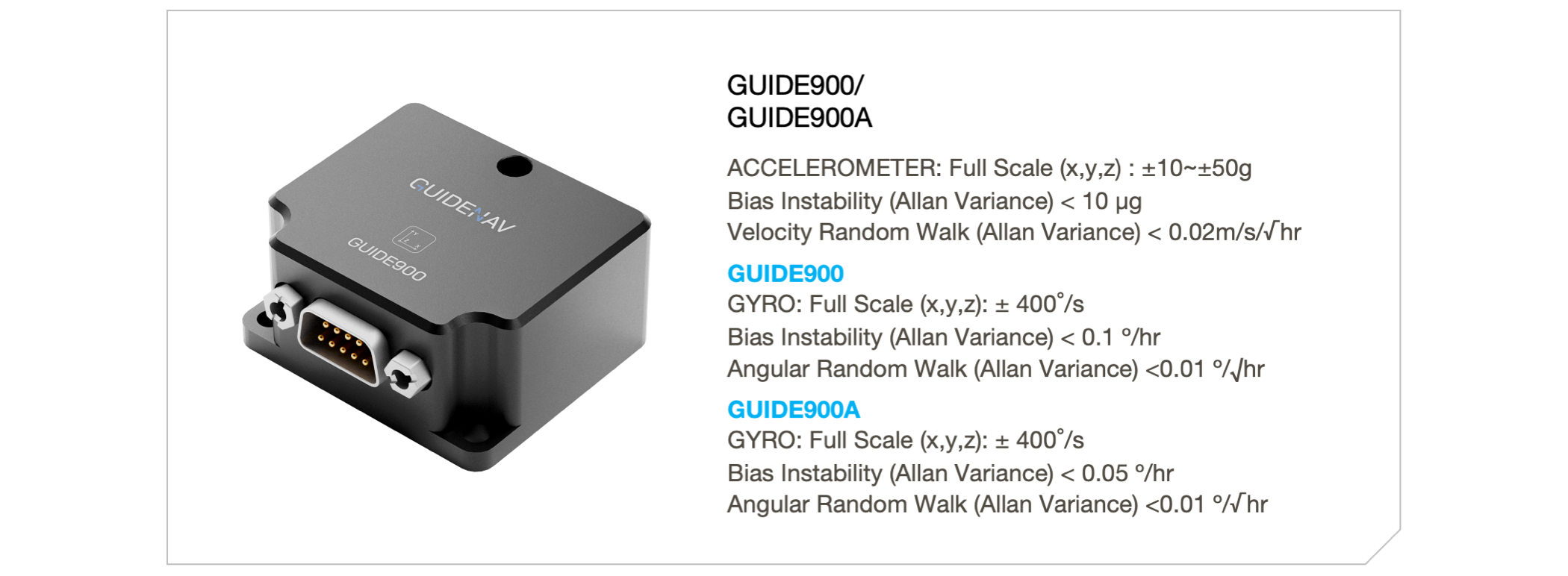

The GuideNav MEMS IMU GUIDE900 is factory-calibrated with a scale-factor nonlinearity of less than 100 ppm and cross-axis coupling below 200 ppm — yet poor installation alignment can quickly negate that precision.

Stay Clear of Vibration and Stress Zones

Continuous vibration or structural stress gradually alters a MEMS IMU’s internal characteristics. Avoid mounting the sensor near engines, gearboxes, or welded joints. Over time, these mechanical influences can introduce bias drift and reduce long-term stability.

Environmental Control: The Hidden Enemy of IMU Accuracy

Temperature Stability Is Everything

Temperature is the most common cause of drift in a high-precision MEMS IMU. Every sensor has a defined thermal operating range—typically −40 °C to +85 °C. Sudden fluctuations can shift the zero bias or scale factor.

Keep the MEMS IMU within a stable environment using insulation, controlled airflow, or heating elements if necessary. All GuideNav MEMS IMUs are fully temperature-compensated across the entire range, ensuring consistent accuracy in extreme conditions.

Humidity Can Silently Damage Precision

Moisture is another invisible threat. When humidity exceeds 85 % RH, it can infiltrate the package, corrode circuits, and change sensor behavior. Even short-term condensation may trigger temporary bias jumps. Always protect the high-precision IMU inside a sealed housing with desiccants when operating in marine or tropical climates.

Avoid Electromagnetic Interference (EMI)

High-current lines and switching power converters can inject noise into the analog front end of a MEMS IMU. To prevent interference, separate power wiring from signal lines, maintain proper grounding, and use shielded cables. A clean electromagnetic environment is as important as mechanical stability for sustaining long-term precision.

Calibration: The Lifeline of a High-Precision MEMS IMU

Factory Calibration Doesn’t Last Forever

Every MEMS IMU leaves the factory calibrated for bias, scale factor, and orthogonality—but those parameters drift over time due to temperature cycles, vibration, and mechanical stress. To keep a high-precision IMU performing to spec, schedule periodic recalibration every 6–12 months, or sooner for mission-critical systems.

Choose the Right Calibration Approach

If removing the IMU isn’t practical, perform an on-board or real-time calibration using static alignment routines or GNSS-aided estimation.

However, full restoration of precision requires laboratory calibration on a rate table or thermal chamber. This method corrects all six axes and compensates for temperature-dependent drift, ensuring the MEMS IMU maintains tactical-grade performance across environments.

Always Verify the Result

Calibration isn’t complete until it’s verified. Compare post-calibration data with reference motion profiles or ground-truth sensors to confirm stability and accuracy.

Neglecting verification can leave hidden errors that quietly degrade performance—defeating the purpose of recalibration.

Operation & Handling: Precision Lives in the Details

Warm Up Before You Trust the Data

A MEMS IMU needs time to reach thermal and electronic stability after power-on. Most high-precision IMUs require a warm-up period of 1–30 minutes, depending on model and environment. Collecting data too early can result in temporary bias several times higher than its rated value.

Avoid Frequent Power Cycling

Repeatedly turning the IMU on and off resets its internal filters and introduces transient bias changes. Keep the MEMS IMU continuously powered during critical data collection to ensure consistent performance and seamless data continuity.

Handle With Care — Always

Despite their rugged design, high-precision MEMS IMUs contain delicate microstructures. Drops, shocks, or improper handling can cause subtle but permanent degradation in accuracy. During transport, use padded containers and secure connectors. Regularly inspect cables, mounts, and housings — mechanical stress or loose wiring often precedes sensor drift.

GuideNav Expert Insight

At GuideNav, we’ve seen how a simple oversight—poor mounting, skipped calibration, or thermal drift—can turn a high-precision MEMS IMU into an unreliable sensor. Real-world integration is never just about specs; it’s about discipline in installation, calibration, and long-term maintenance.

That’s why the GuideNav MEMS IMUs are engineered for professional integrators who demand consistent, field-proven accuracy. Each unit is fully temperature-compensated, orthogonally calibrated, and protected by a rugged aluminum housing designed to withstand the toughest vibration and environmental conditions.

Whether your project involves UAVs, autonomous vehicles, or industrial robotics, applying the right practices will let your MEMS IMU perform exactly as designed—stable, reliable, and ready for mission-critical work.