In the field of high-precision navigation, Fiber Optic IMUs (Inertial Measurement Units) and INSs (Inertial Navigation Systems) are widely deployed in defense, aerospace, and autonomous platforms. Yet, one question often gets overlooked: how long do these systems remain reliable? Without reliable aging tests and lifecycle assessments, critical missions risk unexpected sensor drift, degraded accuracy, or even complete system failure. For mission-critical platforms, this is not an acceptable gamble.

Aging tests for Fiber Optic IMUs and INSs are not redundant costs—they are scientific methods to forecast shelf life, establish warranty periods, and ensure mission reliability under real-world stress.

When engineers or procurement teams look at Fiber Optic IMUs and INSs, the first questions are often about accuracy and cost. But another issue matters just as much—how long will the system stay reliable once it leaves the factory? Aging tests provide the missing piece of the puzzle, giving users confidence that their navigation unit will perform not just today, but for years of service in real operations.

Table of contents

Why Do Fiber Optic IMU/INS Require Aging Tests?

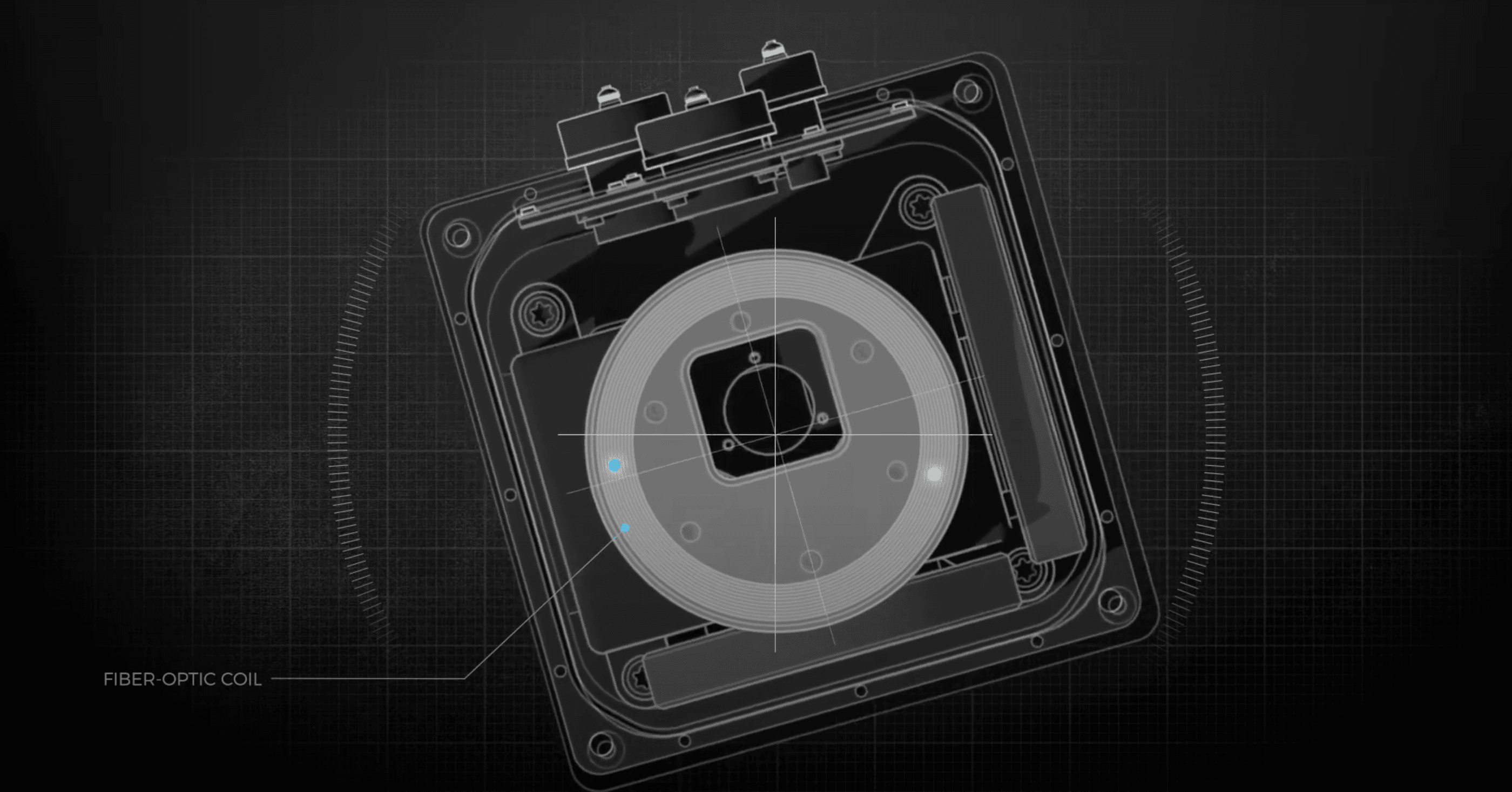

It’s easy to assume that fiber optic gyros and accelerometers will last forever because they have no moving parts. In reality, that’s not the case. Light sources dim, fibers relax under stress, and electronic components slowly age. Over time, these small changes add up and begin to affect bias stability and overall accuracy.

On top of that, temperature swings, vibration, and humidity put additional stress on the system, often accelerating drift. For defense, aerospace, and industrial projects that demand reliability for ten years or more, guessing is not enough. Only structured aging tests can give a clear picture of how the system will hold up under real conditions.

How Is Shelf Life Scientifically Estimated?

Instead of relying on guesswork, engineers use three proven approaches to forecast the usable life of a Fiber Optic IMU or INS:

- Accelerated Life Testing (ALT):Run the unit in extreme heat, humidity, or vibration to compress years of wear into weeks, then apply reliability models such as Arrhenius to predict lifespan.

- Drift Tracking:Monitor bias and scale factor drift over thousands of operating hours, turning raw data into a curve that reveals when performance will fall outside acceptable limits.

- Environmental Stress Screening (ESS):Apply rapid thermal cycles and shocks at the factory stage to weed out early failures before the unit even ships.

Together, these methods provide both manufacturers and users with evidence-based shelf life predictions, rather than optimistic marketing numbers.

Aging Tests vs. Conventional Tests: Key Differences

At first glance, aging tests might sound like just another round of quality control. After all, every Fiber Optic IMU or INS already goes through a factory acceptance test before shipping. But here is the crucial difference: conventional testing tells you whether the unit works today, while aging tests are designed to answer whether it will still work years from now. This forward-looking perspective is what makes aging tests indispensable for defense, aerospace, and industrial customers who cannot afford mid-mission failures.

| Aspect | Conventional Testing | Aging Testing |

|---|---|---|

| Objective | Verify factory compliance | Evaluate long-term reliability |

| Duration | Short-term (hours to days) | Long-term (hundreds to thousands of hours) |

| Conditions | Normal temperature & environment | Accelerated stress: heat, humidity, vibration, shock |

| Key Metrics | Initial accuracy, noise, bias | Drift curves, failure rate, lifetime distribution |

| Outcome | Pass/fail quality control | Shelf life prediction, warranty cycle, lifecycle cost evaluation |

| Value | Ensures readiness at shipment | Ensures reliability over 5–10 years of service |

Put simply: a unit that passes conventional tests may still fail early in the field, while one that survives aging tests has already proven its endurance.

What Is the Practical Value of Aging Tests?

For many decision-makers, the first question about aging tests is not “how” but “why”. Why invest time and resources into tests that stretch across hundreds or thousands of hours? The answer lies in the hidden costs of failure. A Fiber Optic IMU or INS that drifts out of tolerance in the middle of a mission can cause far more damage than the expense of preventive testing. Whether on a submarine, an unmanned aerial vehicle, or a satellite, there is usually no option to swap out a faulty unit once the mission begins. This is why aging tests deliver value far beyond the laboratory.

- Defining Warranty Periods:Manufacturers use aging data to set realistic warranty terms—whether that means 2 years, 5 years, or even 10 years—giving buyers clarity and confidence.

- Planning Lifecycle Costs (LCC):By modeling drift and reliability curves, defense and aerospace customers can budget maintenance and replacement cycles with precision.

- Reducing Mission Risk:Most importantly, aging tests prevent catastrophic mid-operation failures, ensuring that platforms remain combat-ready, mission-ready, or industry-compliant.

In short, aging tests are not a luxury—they are a practical insurance policy for the entire mission lifecycle.

How Do Engineers Deal with Long-Term Concerns?

Even with aging tests in place, engineers still face practical challenges when deploying Fiber Optic IMUs and INSs over many years of service. One of the most pressing concerns is bias drift—the tendency for small errors to build up over time. To counter this, systems are often powered on regularly, allowing self-calibration routines to refresh stability and prevent silent degradation.

Another factor is storage conditions. A navigation unit kept in a hot, humid warehouse will age much faster than one stored in a controlled, dry environment. This means shelf life is not only a matter of design but also of logistics and maintenance discipline.

Finally, unlike consumable items that carry a simple “manufacture date + expiration date,” the usable life of a Fiber Optic IMU or INS cannot be stamped with a single number. Instead, it depends on drift models, stress test data, and continuous monitoring of performance thresholds. This makes aging experiments not just a technical necessity, but a roadmap for engineers to manage reliability throughout the system’s lifecycle.

From Datasheet to Decade: What Really Matters

The true test of a Fiber Optic IMU or INS is not how it performs on day one, but how it holds up years later. Aging tests bridge that gap, turning long-term reliability into measurable data. They prove whether a system can stay mission-ready across thousands of hours, not just at factory shipment.

At GuideNav, every Fiber Optic IMU and INS we deliver is backed by aging experiments, stress screening, and drift analysis. For defense, aerospace, and industrial users, this means more than specifications—it means confidence that the system will remain dependable throughout its service life.