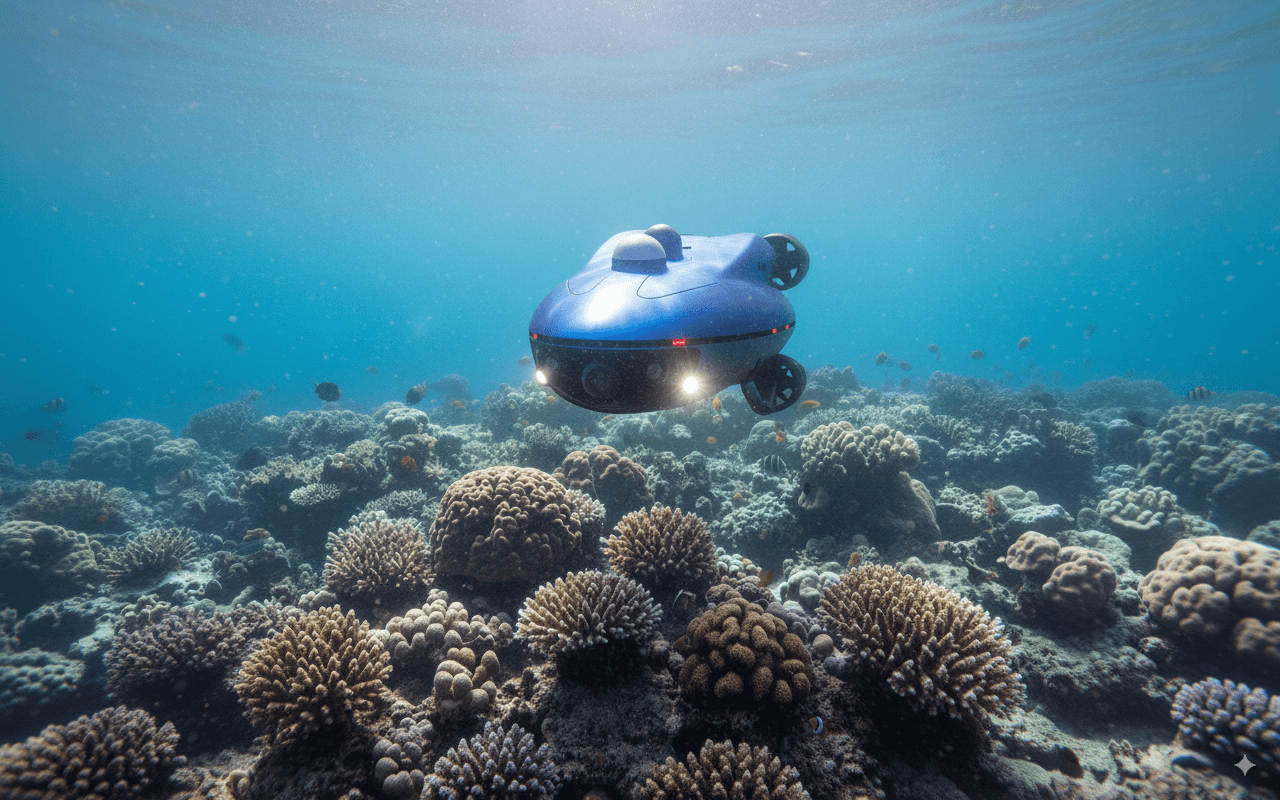

Subsea navigation is unforgiving. Without GPS signals, underwater vehicles rely entirely on inertial sensors to keep track of their position. A small drift per minute can accumulate into kilometers of error over long missions. For operators mapping pipelines or exploring deep waters, such deviations can mean wasted missions, higher costs, and compromised safety. That’s why the choice between Fiber Optic Gyroscopes (FOG) and MEMS IMUs is so critical.

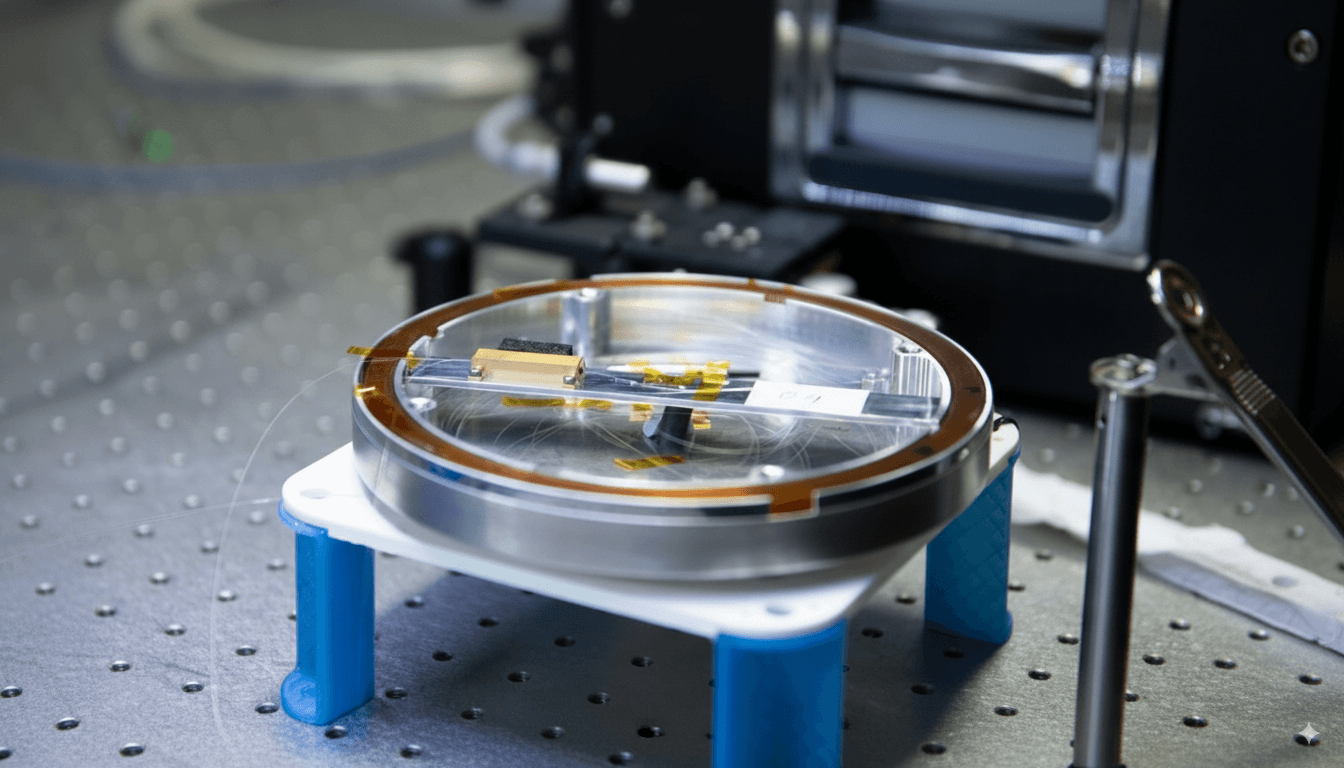

FOG gyroscopes maintain ultra-low drift and long-term stability under GNSS-denied subsea conditions, while MEMS IMUs offer compact, low-power alternatives better suited for short-duration inspections and cost-sensitive platforms.

The debate between FOG and MEMS is not about which technology is newer, but about which one truly withstands the harsh realities of subsea navigation. By comparing their performance across accuracy, environmental resilience, vibration tolerance, SWaP, and integration, we can reveal where each technology excels—and where it falls short. This structured perspective helps operators match the right sensor to the right underwater mission.

Table of contents

Cost and Lifecycle: Which Option Delivers Better Value Over Time?

FOG Economics

FOG gyroscopes come with a higher upfront cost due to their precision optical components and manufacturing complexity. However, they deliver long service life, minimal recalibration needs, and consistent performance across years of operation. For operators running repeated long-duration subsea missions, the lower maintenance and stable accuracy often offset the initial investment. In defense and oil & gas applications, lifecycle cost efficiency is a key reason FOG remains dominant.

MEMS Economics

MEMS sensors are cost-effective, mass-produced, and widely available, making them attractive for budget-sensitive projects. Their lower unit price enables deployment on smaller ROV fleets or disposable platforms. However, MEMS units may require more frequent recalibration, replacement, or redundancy, which can raise the total cost of ownership in high-demand subsea missions. Their shorter operational lifespan also limits their value in long-term programs.

Comparison

- FOG: Higher upfront cost but lower lifecycle expenses thanks to durability and stability.

- MEMS: Cheaper to acquire but may increase overall costs through recalibration and replacements.

- Verdict: For sustained subsea operations, FOG provides better long-term value; MEMS is the economical choice for low-cost, short-term tasks.

Calibration and Maintenance: Which Sensor Requires More Upkeep?

FOG Maintenance

FOG gyroscopes are factory-calibrated and highly stable over time. Once integrated into a subsea navigation system, they require little to no recalibration during their operational life. Their optical design means fewer drift variations, and scheduled maintenance often focuses only on system-level checks rather than the sensor itself. This makes FOGs attractive for operators who value low downtime and predictable reliability.

MEMS Maintenance

MEMS sensors, due to their higher sensitivity to temperature, stress, and aging effects, often require periodic recalibration to maintain acceptable performance. In subsea conditions where environmental factors shift quickly, MEMS units may need compensation updates more frequently. Some systems rely on advanced algorithms for in-field calibration, but this increases processing requirements and operational complexity.

Comparison

- FOG: Minimal upkeep, long-term stability without repeated calibration.

- MEMS: Requires frequent recalibration or algorithmic compensation to sustain accuracy.

- Verdict: FOG ensures smoother operations with lower maintenance overhead, while MEMS demands more effort to keep performance in check.

Data Quality: Which Sensor Provides More Reliable Mapping and Survey Results?

FOG Data Quality

FOG gyroscopes deliver high-resolution, low-noise, and drift-free measurements that are essential for subsea mapping and surveying. When integrated with multibeam sonars or side-scan systems, FOG-based navigation ensures precise georeferencing of seabed features and pipeline routes. The stable heading and velocity estimates reduce error accumulation, enabling survey-grade accuracy over extended missions without constant external correction.

MEMS Data Quality

MEMS IMUs can provide sufficient data quality for basic inspection tasks and short-range navigation, but their noise floor and drift rates limit their performance in survey-class operations. Even when fused with DVLs, MEMS outputs may introduce small inconsistencies that compound during long missions, leading to degraded map alignment and less reliable feature localization. This makes MEMS more suitable for reconnaissance or low-cost inspection robots rather than detailed mapping.

Comparison

- FOG: Delivers survey-grade accuracy, reliable for detailed mapping and long missions.

- MEMS: Adequate for short inspections, but insufficient for high-resolution survey requirements.

- Verdict: For applications demanding precise mapping and repeatable survey quality, FOG is the only dependable option.

Proven Use Cases: Where Have FOG and MEMS Been Successfully Applied Underwater?

FOG Applications

FOG gyroscopes have been widely adopted in defense-grade AUVs, deep-sea research vehicles, and offshore oil & gas survey platforms. They enable extended operations such as pipeline inspection, seabed mapping, and mine countermeasure missions. Their resilience in GNSS-denied environments makes them the backbone of long-duration underwater navigation, ensuring mission-critical accuracy where external aids are limited or unreliable.

MEMS Applications

MEMS IMUs are common in lightweight inspection ROVs, diver navigation units, and short-range observation drones. Their small size and low cost make them ideal for tasks like hull inspections, harbor surveillance, and shallow-water reconnaissance. While less precise than FOG, MEMS units can be deployed in larger numbers, offering redundancy or disposability for missions where cost efficiency outweighs ultra-high accuracy.

Comparison

- FOG: Dominant in long-range, high-precision subsea missions with stringent accuracy demands.

- MEMS: Effective in cost-sensitive, short-duration, or shallow-water applications.

- Verdict: FOG proves its value in mission-critical subsea operations, while MEMS shines in flexible, low-cost deployments.

Decision Making: Which Sensor Should You Choose for Your Subsea Platform?

FOG Choice

FOG gyroscopes are the preferred solution for long-endurance, high-precision subsea platforms. Their stability, low drift, and robustness make them indispensable for military-grade AUVs, deep-sea research missions, and offshore energy operations. When mission success depends on navigation accuracy without frequent external corrections, FOG remains the clear winner.

MEMS Choice

MEMS IMUs are the practical option for compact, cost-sensitive, and short-duration subsea platforms. They fit well in inspection-class ROVs, diver aids, and shallow-water drones where low SWaP and affordability outweigh the need for survey-grade accuracy. MEMS is the enabler of flexible, scalable underwater robotics, especially in commercial and entry-level defense use.

Comparison

- FOG: High cost but unmatched performance for long-term, critical operations.

- MEMS: Affordable and compact, ideal for small-scale or short missions.

- Verdict: The right choice depends on your platform’s mission profile—FOG for precision, MEMS for flexibility.

At GuideNav, we understand that subsea navigation is never one-size-fits-all. That’s why our portfolio includes both high-performance FOG-based navigation units for deep-sea and defense applications, as well as compact MEMS solutions for lighter ROVs and inspection tasks. Whether your project demands endurance, precision, or cost-effectiveness, our team can help configure the right inertial solution for your subsea platform.