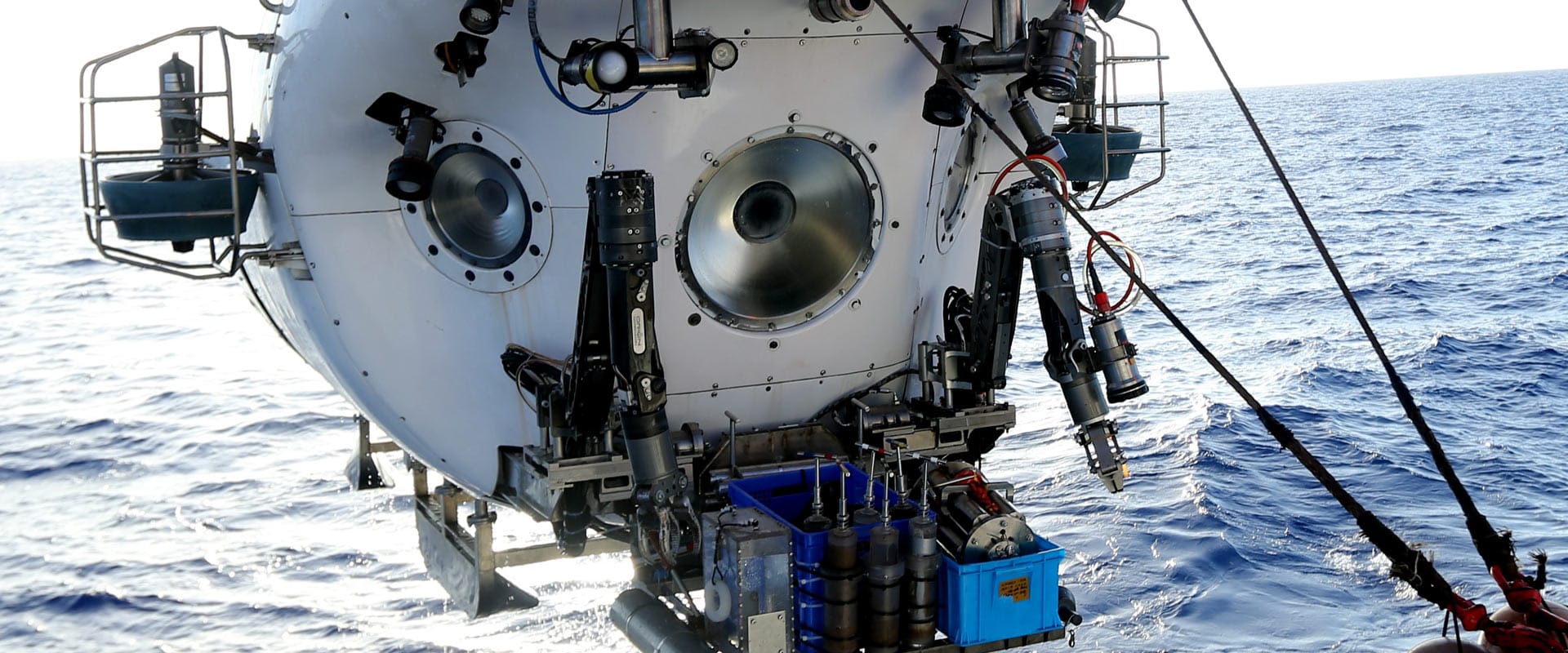

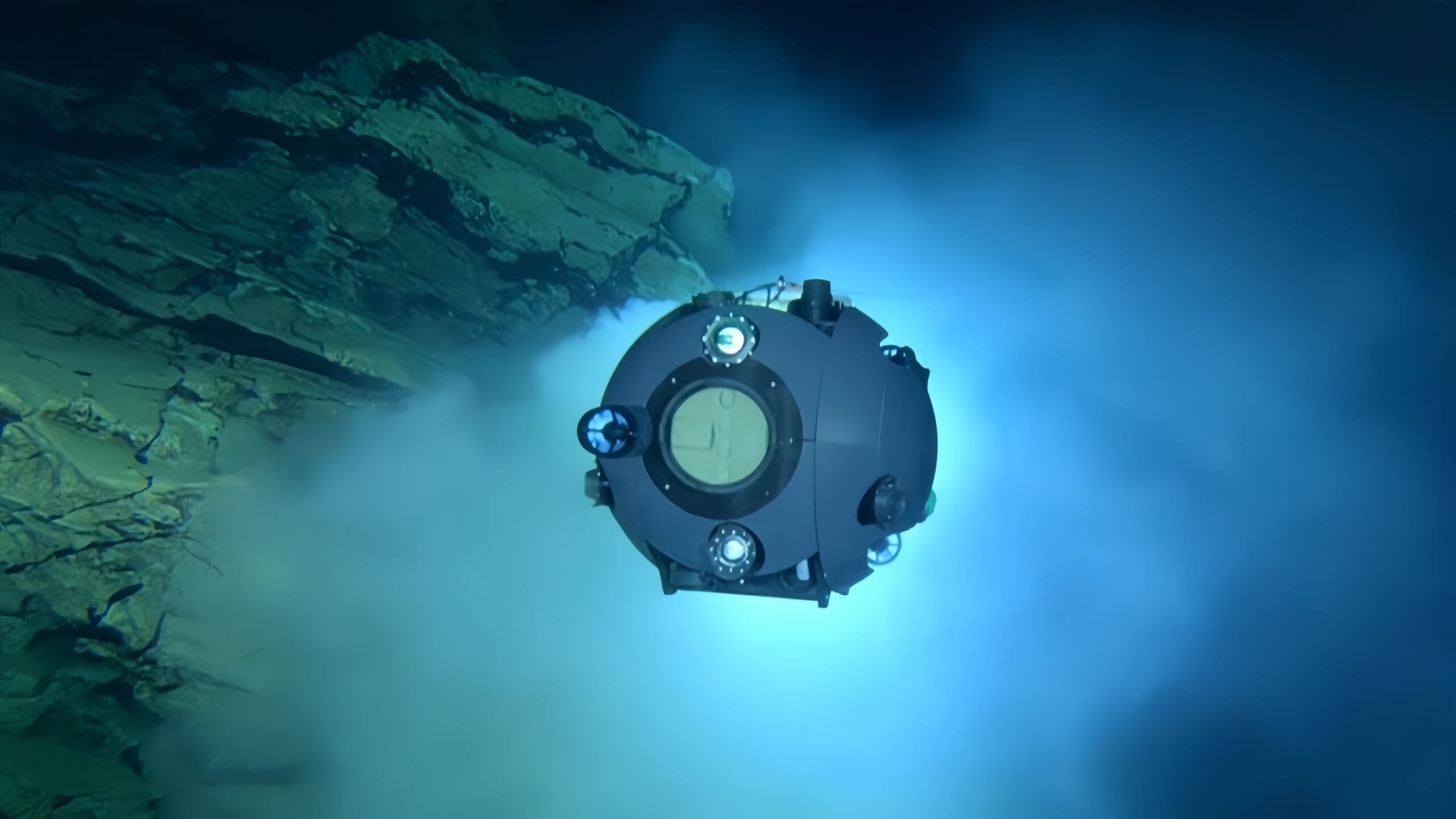

Subsea navigation is unforgiving. Without GPS signals, underwater vehicles rely entirely on inertial sensors to keep track of their position. A small drift per minute can accumulate into kilometers of error over long missions. For operators mapping pipelines or exploring deep waters, such deviations can mean wasted missions, higher costs, and compromised safety. That’s why the choice between Fiber Optic Gyroscopes (FOG) and MEMS IMUs is so critical.

FOG gyroscopes maintain ultra-low drift and long-term stability under GNSS-denied subsea conditions, while MEMS IMUs offer compact, low-power alternatives better suited for short-duration inspections and cost-sensitive platforms.

The debate between FOG and MEMS is not about which technology is newer, but about which one truly withstands the harsh realities of subsea navigation. By comparing their performance across accuracy, environmental resilience, vibration tolerance, SWaP, and lifecycle factors, we can reveal where each technology excels—and where it falls short. This structured perspective helps operators match the right sensor to the right underwater mission.

Table of contents

Accuracy and Drift Over Long-Duration Missions: Which Sensor Performs Better?

FOG Performance

FOG sensors exploit the Sagnac effect to measure angular velocity, independent of mechanical parts. This design delivers exceptionally low drift rates, often <0.05 °/h, making them highly stable for missions lasting 6–10 hours or more. In subsea mapping or pipeline inspection, FOG-equipped AUVs maintain reliable heading estimates without constant external updates, ensuring survey accuracy and mission efficiency.

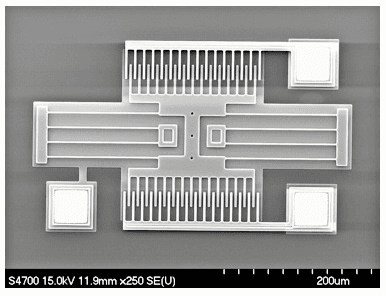

MEMS Performance

MEMS gyros measure rotation through vibrating structures. Despite improvements, their bias instability is still in the 1–10 °/h range, which leads to significant cumulative errors in GNSS-denied environments. MEMS units can manage short dives or inspection tasks lasting under one hour, but over long durations, drift accumulation requires frequent correction via DVLs, USBLs, or acoustic beacons. This dependence limits autonomy in deep-sea operations.

Comparison

FOG: Unmatched stability, suitable for long-duration surveys.

MEMS: Adequate only for short-range, time-limited missions.

Verdict: FOG is the superior choice when accuracy over time is mission-critical.

Environmental Robustness: Which Technology Withstands Subsea Pressure and Temperature Extremes?

FOG Robustness

FOGs use optical coils and solid-state electronics, making them inherently resistant to pressure, salinity, and wide thermal variations. Since no vibrating structures are involved, pressure at depth has minimal effect on performance. Temperature drift is predictable and can be factory-compensated, ensuring consistent heading accuracy even in Arctic or tropical waters.

MEMS Robustness

MEMS sensors are built on silicon microstructures, which are sensitive to thermal expansion, stress, and pressure fluctuations. Subsea conditions—especially rapid temperature shifts or high salinity—can degrade their bias stability and scale factor linearity. Compensation algorithms and encapsulation help, but MEMS generally requires active recalibration when environmental conditions vary.

Comparison

FOG: More robust in long-term exposure to subsea environments.

MEMS: Sensitive to environmental stress, requires frequent correction.

Verdict: FOG remains the reliable option for deep-sea missions, while MEMS fits shallow or controlled environments.

Vibration and Shock: Which Sensor Maintains Stability Under Dynamic Loads?

FOG Stability

FOG gyroscopes, with no moving mechanical parts, are inherently less sensitive to vibration-induced errors. In subsea platforms such as AUVs operating near seabed currents or ROVs handling tools, FOGs maintain stable outputs even under constant micro-vibrations or sudden shocks. Their optical design ensures that dynamic loads have minimal influence on bias and scale factor, which is why FOGs are trusted in naval mine countermeasure systems and offshore construction.

MEMS Stability

MEMS sensors, despite their rugged micro-scale construction, are inherently more vulnerable to vibration noise and shock impacts. Vibrating structures can pick up unwanted frequencies, causing false angular rate readings or temporary output instability. While damping and filtering techniques improve performance, MEMS gyros often require extensive signal processing to remain usable in high-vibration environments such as thruster-driven subsea drones.

Comparison

- FOG: Delivers stable readings under vibration and sudden shock, minimizing error propagation.

- MEMS: Lightweight but prone to vibration-induced noise, requiring heavy filtering.

- Verdict: For platforms exposed to turbulence, propeller-induced vibration, or subsea tool operations, FOG clearly provides the more stable and mission-proof solution.

Size, Weight, and Power: Which Sensor Fits SWaP-Constrained Platforms?

FOG SWaP Characteristics

FOG sensors traditionally come with larger optical coils and higher power requirements. Even with recent miniaturization, a tactical-grade FOG can weigh several hundred grams and consume multiple watts of power. On small AUVs or battery-limited ROVs, this can reduce endurance or payload capacity. However, for mid- to large-scale subsea vehicles, the size and power tradeoff is often justified by the unmatched accuracy and stability.

MEMS SWaP Characteristics

MEMS IMUs are inherently compact, lightweight, and energy-efficient. Many tactical MEMS units weigh under 50 grams and operate on less than 1 watt. This makes them ideal for small inspection drones, portable diver navigation units, or payloads where every gram and milliamp counts. Their small footprint allows integration into tight enclosures, enabling agile vehicle designs.

Comparison

- FOG: Bulkier and power-hungry, best for platforms with sufficient space and energy budgets.

- MEMS: Optimized for SWaP-constrained systems, enabling lightweight and low-power designs.

- Verdict: When compactness and efficiency are top priorities, MEMS is the natural choice; for missions prioritizing accuracy over endurance, FOG remains the benchmark.

Integration With Subsea Aids: Which Sensor Works Best With DVL and USBL?

FOG Integration

FOG gyroscopes provide a high-stability reference that greatly enhances the performance of Doppler Velocity Logs (DVLs), Ultra-Short Baseline (USBL), and Long Baseline (LBL) acoustic systems. Because FOG outputs remain accurate over time, aiding sensors can update less frequently, reducing navigation errors even when acoustic signals are intermittent or partially blocked. This synergy makes FOG-based INS solutions the standard for survey-class AUVs and long-endurance subsea missions.

MEMS Integration

MEMS IMUs rely more heavily on external aids due to their higher drift and bias instability. While they integrate easily with DVLs and USBLs thanks to their lightweight and digital-friendly design, the frequent need for corrections increases system dependency on acoustic updates. In noisy or signal-degraded environments, MEMS-based navigation may show jumps or degraded positioning quality unless reinforced by advanced sensor fusion algorithms.

Comparison

- FOG: Provides a stable backbone for subsea aiding systems, reducing reliance on frequent corrections.

- MEMS: Easy to integrate but requires constant external updates to compensate for drift.

- Verdict: For missions where acoustic updates may be unreliable, FOG is the safer bet; MEMS can suffice when external aiding is guaranteed and frequent.

From drift stability to environmental resilience, vibration tolerance, SWaP, and system integration, the comparison so far makes it clear that FOG generally outperforms MEMS in demanding subsea conditions, while MEMS remains a practical choice for lighter and shorter missions.

Yet, performance alone does not define the right solution. Cost, maintenance requirements, data quality, and proven applications are equally decisive when selecting a sensor for subsea platforms. In Part II, we will continue this exploration by examining lifecycle economics, upkeep, mapping reliability, and real-world use cases-before arriving at a final decision on which technology holds better under water.