Defense procurement officers often struggle when choosing between Fiber-Optic Gyroscopes (FOGs) and Ring Laser Gyroscopes (RLGs). Both promise navigation-grade performance, yet the wrong decision can lead to overspending on unnecessary precision or deploying systems that fail in harsh environments. With program budgets under pressure and mission success at stake, buyers cannot afford guesswork. The key is to evaluate these technologies not by datasheet numbers alone, but by procurement priorities—accuracy, reliability, lifecycle costs, environmental resilience, and mission suitability—where FOG consistently proves to be the smarter, lower-risk investment.

“FOG and RLG are both established gyroscope technologies for defense navigation. But when buyers compare them through the lens of procurement, FOG delivers the optimal balance of performance, reliability, and lifecycle cost for nearly every mission outside of strategic deterrence.”

When you’re evaluating navigation sensors, the datasheet only tells part of the story. What really matters is how the technology performs once it leaves the lab—out at sea, in the air, or on the battlefield. This guide breaks down the five areas every procurement team should look at—accuracy, reliability, lifecycle costs, environmental toughness, and application fit—to show why Fiber-Optic Gyroscopes are now the go-to choice for most defense programs.

Table of contents

Is Ultra-High Precision Always Necessary?

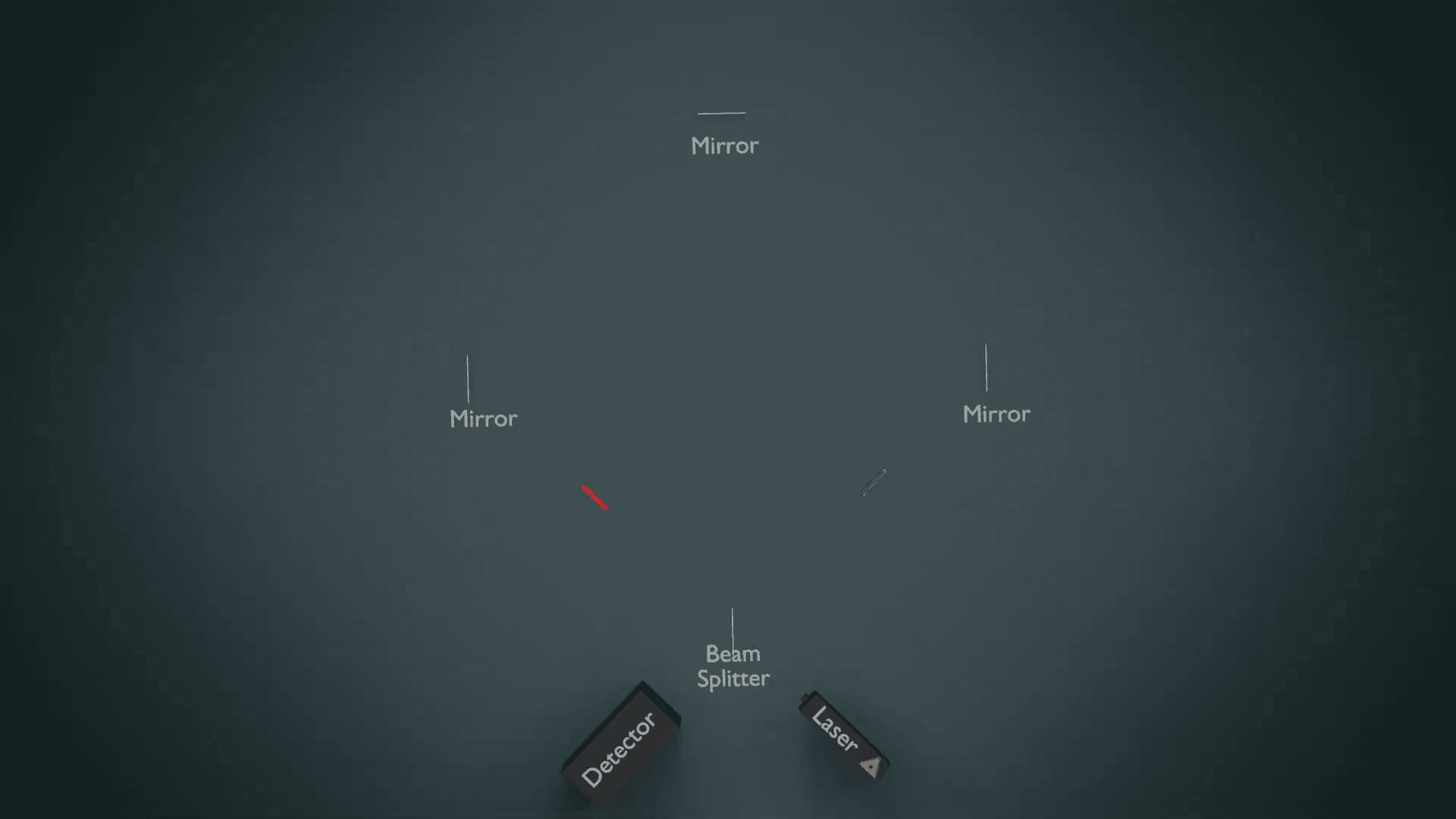

Accuracy is always a key specification in defense procurement, but not every mission demands the extreme precision once associated with RLGs. The real question is whether your program needs strategic-level accuracy or just proven mission-ready stability.

Accuracy Comparison

- RLGs:Bias stability as low as 001 °/h, vital for nuclear submarines, ICBMs.

- FOGs:Modern units reach 005–0.01 °/h, adequate for UAVs, ships, vehicles, missiles.

Procurement Insight: Paying for ultra-high precision makes sense only for strategic deterrence. For most missions, FOG accuracy is more than sufficient.

How Critical Is Reliability in Long-Term Deployment?

Reliability is often the hidden driver of procurement success. A system that works perfectly on day one but requires constant maintenance quickly becomes a liability for defense programs operating worldwide.

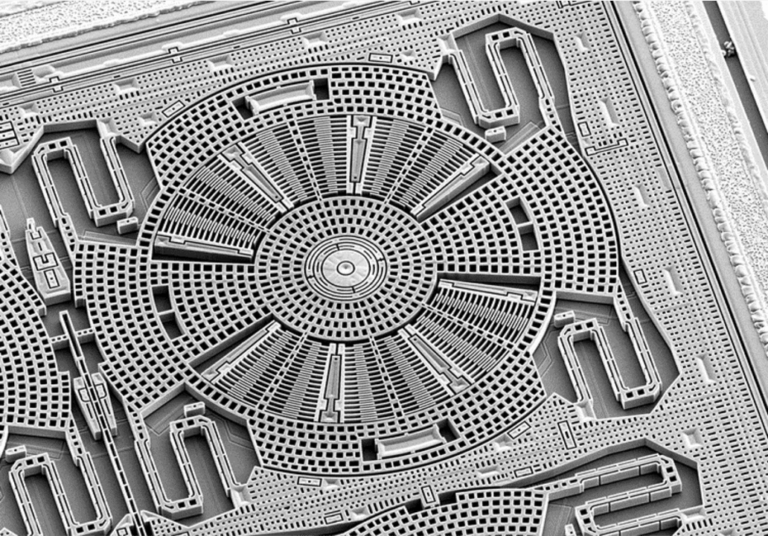

Reliability Factors

- RLGs:Gas lasers + moving parts → calibration and periodic maintenance.

- FOGs:Fully solid-state → no moving parts, virtually maintenance-free.

- Proven in UAVs, naval fleets, ground systems.

Procurement Insight: Every maintenance cycle is downtime. FOG keeps platforms operational longer, with less logistical burden.

What Do Lifecycle Costs Really Look Like?

Unit price is only the starting point. Defense buyers know the true measure is Total Cost of Ownership (TCO) over the entire service life, often spanning decades. Here’s where FOG outperforms RLGs decisively.

FOG vs RLG Comparison Tables

| Factor | FOG | RLG |

|---|---|---|

| Initial Cost | Medium | High |

| Maintenance | Negligible | Frequent & costly |

| Service Life | 10–15 years | 7–10 years |

| TCO (20 yrs) | Lowest in class | 2–3× higher |

Procurement Insight: FOGs deliver long-term savings, freeing budgets for other mission-critical systems.

Can the System Withstand Harsh Operational Environments?

Defense missions take place in deserts, oceans, and arctic zones—not in climate-controlled labs. Gyroscopes must withstand shock, vibration, and extreme weather while maintaining stable performance.

Environmental Resilience

- RLGs:Sensitive to vibration, temperature, shock; need protective stabilization.

- FOGs:Qualified to MIL-STD-810G → operate in –40 °C to +70 °C, survive 20,000 g shock, resist salt, humidity, dust.

Procurement Insight: A sensor that needs protection is a risk. FOG delivers proven accuracy directly in the field.

Which Applications Benefit Most from FOG Technology?

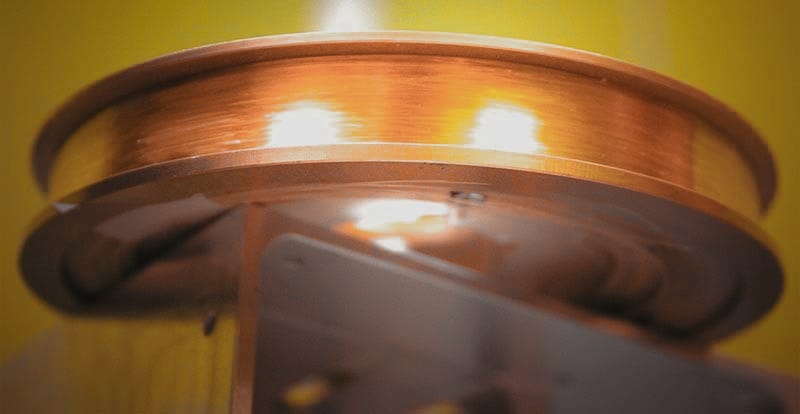

While RLGs still find niche use in strategic systems—such as nuclear submarines or intercontinental ballistic missiles where extreme precision is mandatory—these cases are limited. In contrast, FOGs have become the dominant choice across a wide spectrum of defense applications.

They are now standard in UAVs requiring stable navigation during GNSS denial, naval vessels operating in salt and humidity, tactical missiles that must endure intense vibration and acceleration, and armored vehicles where ruggedness and reliability are critical. Even beyond defense, FOGs are widely deployed in industrial robotics, surveying, and energy exploration, thanks to their balance of accuracy and durability.

Procurement perspective: For more than 90% of defense and industrial missions, FOGs provide the required precision, greater resilience, and lower total cost of ownership—making them the safer and more future-proof investment.

Ready to Source a Proven FOG Solution?

For procurement officers, the choice often comes down to balancing mission performance, lifecycle cost, and long-term support. That’s exactly where Fiber-Optic Gyroscopes stand out. They deliver the accuracy most missions demand, the robustness to survive harsh deployments, and the reliability to reduce hidden maintenance costs.

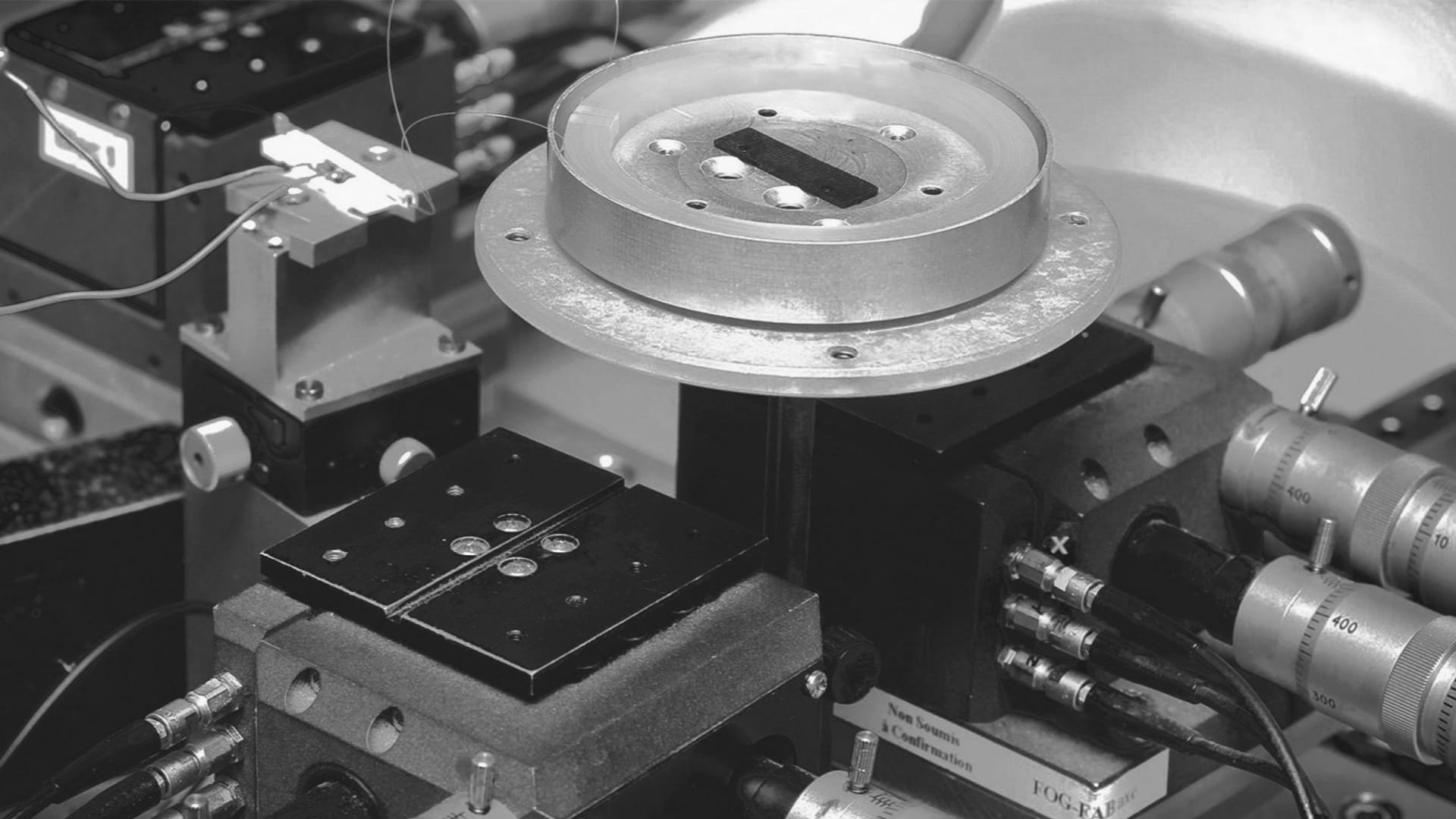

At GuideNav, we provide a full portfolio of tactical- to navigation-grade FOGs, all qualified to defense standards and trusted in global programs. Our systems are non-ITAR restricted, enabling smoother international procurement, and are backed by comprehensive lifecycle support to ensure long-term confidence.

If your next program requires a dependable FOG solution, contact our team today to request datasheets, lead times, and tailored procurement guidance.