In my work developing navigation systems, I’ve found that true reliability comes from independence—not from reliance on external signals. That’s why Inertial Navigation Systems (INS) play such a critical role: they operate entirely on internal measurements, providing consistent and continuous navigation across a wide range of environments, from autonomous vehicles to aerospace platforms.

An Inertial Navigation System (INS) determines position, velocity, and orientation using only internal motion sensors, enabling precise navigation across a wide range of applications—including autonomous systems, underwater platforms, and mission-critical defense operations.

Before selecting an INS for your application, it helps to build a clear understanding of its working principles and system types.

Table of contents

What Is An Inertial Navigation System (INS)?

An Inertial Navigation System (INS) is a self-contained system that uses internal motion sensors—typically accelerometers and gyroscopes—to continuously calculate a platform’s position, velocity, and orientation in three-dimensional space. Because it does not rely on any external references, INS is especially valuable in environments where consistent, uninterrupted navigation is required, including underwater, underground, and high-dynamic defense applications.

What Are The Core Components Of An INS?

In my experience designing INS solutions, every system starts with three essential components: gyroscopes, accelerometers, and a navigation processor. To improve accuracy and stability, we often integrate additional sensors—like GNSS receivers, magnetometers, or barometric altimeters—for advanced sensor fusion. This architecture allows the INS to maintain reliable motion tracking across diverse and challenging environments.

Gyroscopes

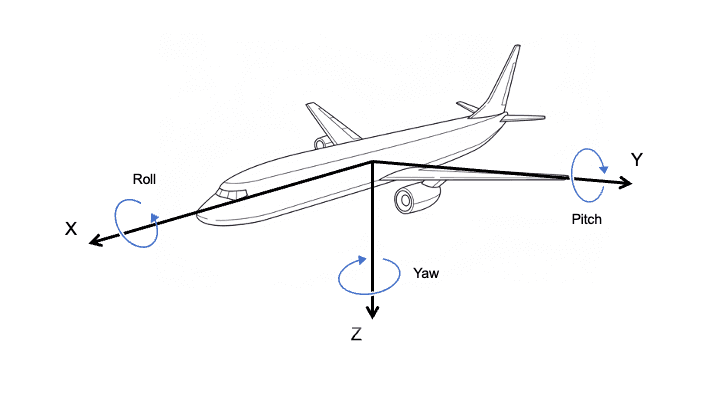

Gyroscopes measure angular velocity along three orthogonal axes (X, Y, Z), providing essential data for computing orientation—roll, pitch, and yaw. MEMS gyroscopes are widely used for compact applications, while FOG (Fiber Optic Gyroscopes) and RLG (Ring Laser Gyroscopes) offer higher precision and long-term stability for tactical and aerospace-grade systems.

Accelerometers

Accelerometers measure linear acceleration along each axis. When integrated over time, these values yield changes in velocity and displacement. High-performance accelerometers with low bias instability and low noise are crucial for maintaining position accuracy over time.

Inertial Navigation Processor

The processor serves as the computational core of the INS. It fuses input from motion sensors, applies compensation algorithms and filtering, and outputs position, velocity, and orientation in real time. Many systems also support external sensor integration and real-time diagnostics within this unit.

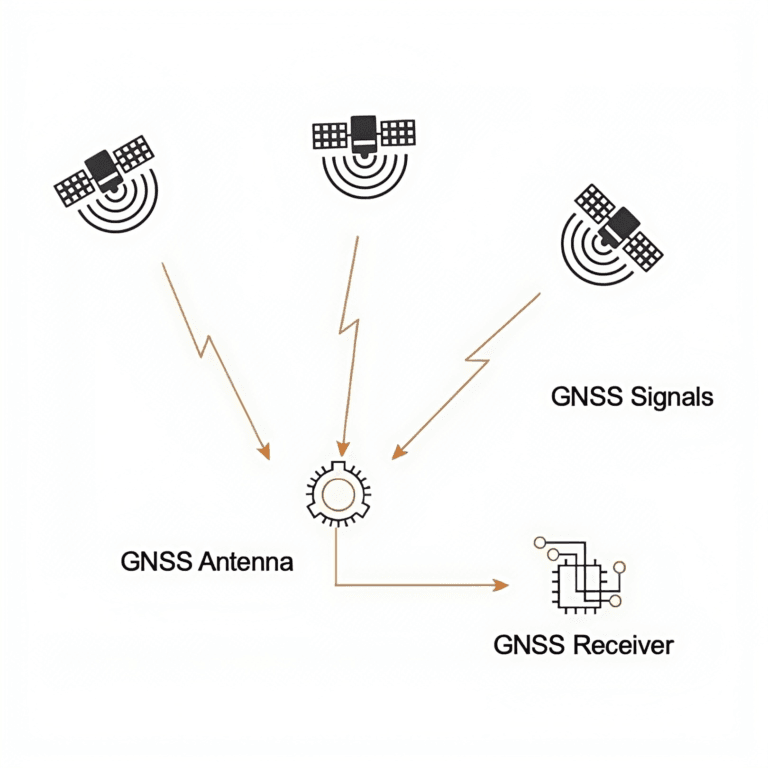

GNSS Receivers

An increasing number of INS solutions now integrate GNSS receivers to improve long-term accuracy and global positioning. By combining inertial measurements with satellite data—typically through extended Kalman filtering—these hybrid systems effectively correct drift and deliver robust navigation performance across autonomous platforms, aerospace systems, and geodetic-grade applications.

Magnetometers

Magnetometers assist in determining heading by measuring the Earth’s magnetic field. While less accurate than gyroscopic solutions, they provide a useful absolute reference—especially in low-dynamic or indoor applications.

Barometric Altimeters

These sensors provide altitude estimation based on atmospheric pressure. They are commonly used in UAVs, aircraft, and ground systems that require vertical reference data in environments where GNSS altitude may be unreliable.

Together, these components form a versatile navigation system capable of delivering high-rate, real-time motion data—whether operating as a pure inertial unit or as part of a tightly integrated GNSS/INS solution designed for complex, dynamic environments.

What Are the Different Types of INS: MEMS, FOG, and RLG?

Inertial Navigation Systems can be broadly categorized based on the type of gyroscope technology they use. The choice of technology determines key performance characteristics such as bias stability, noise, drift, and cost—making it critical to select the right type for your application.

1. MEMS INS (Micro-Electro-Mechanical Systems)

MEMS INS is built using silicon-based micromechanical gyroscopes and accelerometers. Thanks to advances in semiconductor fabrication, these systems are now widely used in compact platforms where size, weight, power, and cost (SWaP-C) are major constraints.

2. FOG INS (Fiber Optic Gyroscope-based INS)

FOG INS relies on the Sagnac effect, using coiled fiber optics to measure rotation. It offers significantly higher stability, lower drift, and better scale factor linearity than MEMS systems, making it ideal for tactical-grade navigation.

3. RLG INS (Ring Laser Gyroscope-based INS)

RLG INS uses laser interference in a closed-loop cavity to detect angular velocity with extremely high precision. This architecture delivers strategic-grade accuracy and is typically deployed in systems where absolute inertial performance is critical.

| INS Type | Advantages | Limitations | Typical Use Cases |

|---|---|---|---|

| MEMS INS |

|

| UAVs, robotics, wearable systems, loitering munitions |

| FOG INS |

|

| Aerospace platforms, defense vehicles, marine systems |

| RLG INS |

|

| Ballistic missiles, spacecraft, high-end aircraft |

How Does INS Works?

When configuring an INS, I always start by defining its initial position, velocity, and orientation. From there, the system relies solely on inertial measurements to estimate every subsequent motion state in real time.

1. Acceleration Measurement

The system uses tri-axial accelerometers to measure linear acceleration in three directions. These values are integrated over time to compute velocity, and then integrated again to calculate changes in position.

2. Angular Rate Measurement

Gyroscopes measure angular velocity along the X, Y, and Z axes. These readings are used to update the system’s orientation through quaternion or Euler angle integration.

3. Dead Reckoning Principle

INS operates through dead reckoning, meaning it estimates the current state based on the previous one and sensor input. This allows it to navigate without external references like GNSS.

4. Error Accumulation and Drift

Because it integrates noisy sensor data, small biases and errors (e.g., bias instability, scale factor error) accumulate over time, leading to drift in both position and orientation.

5. Sensor Fusion and Aiding Inputs

To minimize drift, INS is often combined with external sensors such as GNSS, Doppler Velocity Logs (DVL), barometers, or magnetometers. These aiding sources correct accumulated errors and extend operational accuracy.

This architecture allows the INS to deliver real-time, autonomous navigation in environments where external signals are limited, disrupted, or entirely unavailable—such as during high dynamics or electromagnetic interference.

What Performance Metrics Define the Quality of An INS?

When selecting an Inertial Navigation System, understanding its core performance parameters is essential to ensure it meets mission requirements. The following metrics are most critical:

1. Navigation Accuracy

INS accuracy includes position, velocity, and attitude errors that accumulate over time. High precision is crucial for operations in GNSS-denied environments. The Guidenav GFS120A, for example, offers heading accuracy of 0.01° (1σ), roll/pitch accuracy of 0.005° (1σ), and RTK-level positioning of <2 cm + 1 ppm, with speed error as low as 0.02 m/s.

2. Bias Stability

Bias stability reflects the long-term drift of gyroscopes and accelerometers, which directly impacts navigation endurance. The Guidenav GFS120A features gyro bias stability of 0.003°/h and accelerometer bias stability under 20 μg, making it suitable for high-precision and long-duration autonomous applications.

3. Sensor Noise (Random Walk)

Random walk quantifies short-term sensor noise. Lower ARW and VRW values indicate cleaner, more stable data during motion.

4. Dynamic Performance

Update rate, latency, and bandwidth determine how fast the INS responds to movement. High dynamic performance is critical for UAVs, robotics, and missiles.

5. Environmental Robustness

INS must withstand vibration, shock, and temperature extremes. Compliance with MIL-STD or DO-160 standards ensures reliability in harsh conditions.

Understanding and comparing these metrics allows integrators to choose the appropriate INS for their platform, balancing cost, precision, and environmental demands.

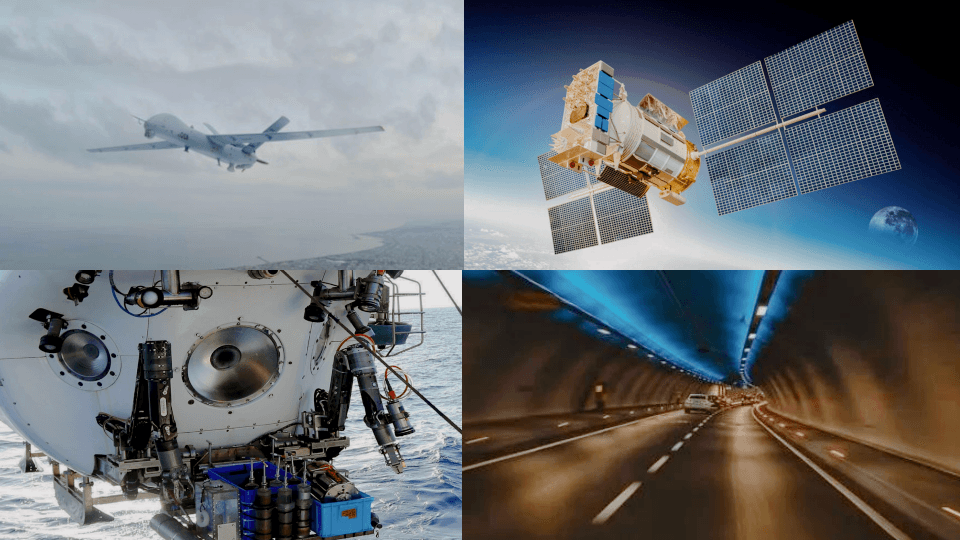

What Are The Typical Applications of INS Across Industries?

Inertial Navigation Systems (INS) are widely used across aerospace, marine, defense, unmanned systems, industrial automation, and underground industries where continuous, signal-independent navigation is critical. In aerospace, they enable precise aircraft and missile guidance; in marine applications, they support submarines and AUVs where GNSS is unavailable. Defense systems rely on INS for targeting, fire control, and navigation in GPS-denied environments. Unmanned platforms like UAVs, UGVs, and UUVs use INS for real-time positioning and sensor fusion. In industrial robotics, INS ensures accurate motion control for AGVs and cranes. In mining and tunneling, INS enables reliable underground positioning for heavy machinery and drilling systems.

How GuideNav Leads in the Inertial Navigation Industry?

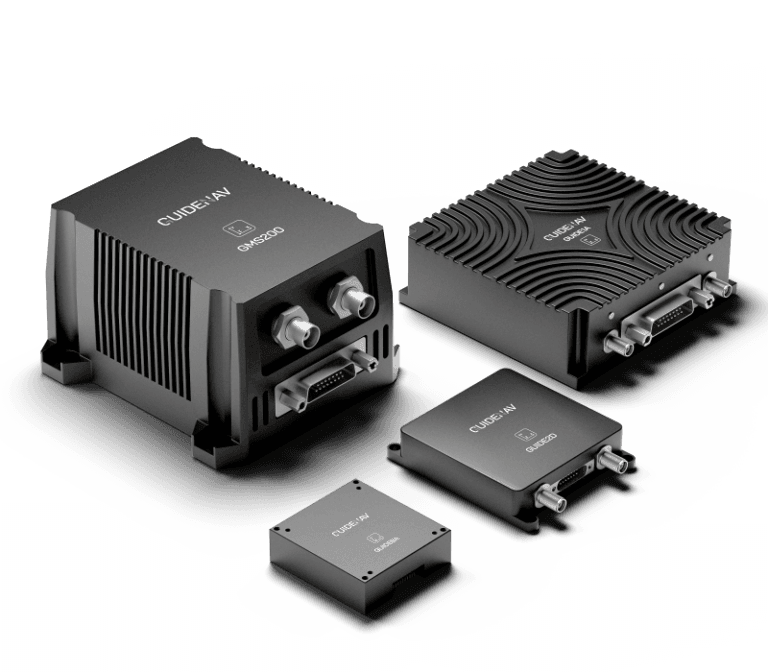

With 15+ years of expertise, GuideNav delivers high-performance inertial navigation solutions trusted by defense, aerospace, and autonomous system integrators worldwide.

Diverse Product Lines

From compact MEMS INS for UAVs to high-precision FOG INS for marine and aerospace, GuideNav covers a full range of mission profiles.

Optimized for SWaP-C

All systems are built for size, weight, power, and cost efficiency—ideal for mobile, embedded, and tactical platforms.

Hybrid Integration Ready

Our INS platforms support seamless fusion with GNSS, DVL, and other aiding sensors via standard interfaces (UART, CAN, Ethernet).

Rugged and Field-Proven

Designed to meet MIL-STD-810H, GuideNav units are shock-resistant, vibration-tolerant, and operate reliably in harsh environments.

GuideNav is the preferred partner for integrators seeking advanced Inertial Navigation Systems (INS) that combine high precision, operational robustness, and full export compliance for demanding defense, aerospace, and autonomous applications.