Having supported countless navigation projects over the past decade, I’ve seen how fiber optic gyroscopes can vary widely in cost—even for similar-looking models. Without a clear understanding of what drives those differences, it’s easy to make costly missteps. Let me walk you through what truly determines the price of a FOG.

Fiber optic gyroscopes (FOGs) are classified into three levels: Tactical-grade ($3,000–$8,000): Used in UAVs, ground vehicles, and basic stabilization systems; Navigation-grade ($8,000–$20,000): Common in maritime navigation, survey equipment, and autonomous systems; Strategic-grade ($20,000–$100,000+): Deployed in missiles, submarines, and high-end aerospace platforms.

The wide price range of FOGs isn’t arbitrary—it’s shaped by technical and application-specific demands. Here’s how it all breaks down.

Table of contents

What Determines the Price of a Fiber Optic Gyroscopes (FOGs)?

Having worked closely with global integrators and defense clients at GuideNav for over 15 years, I can confidently say that FOG pricing is never arbitrary—it reflects a balance of engineering depth, application needs, and quality assurance. Here are the core factors that drive the cost:

1. Performance Specifications

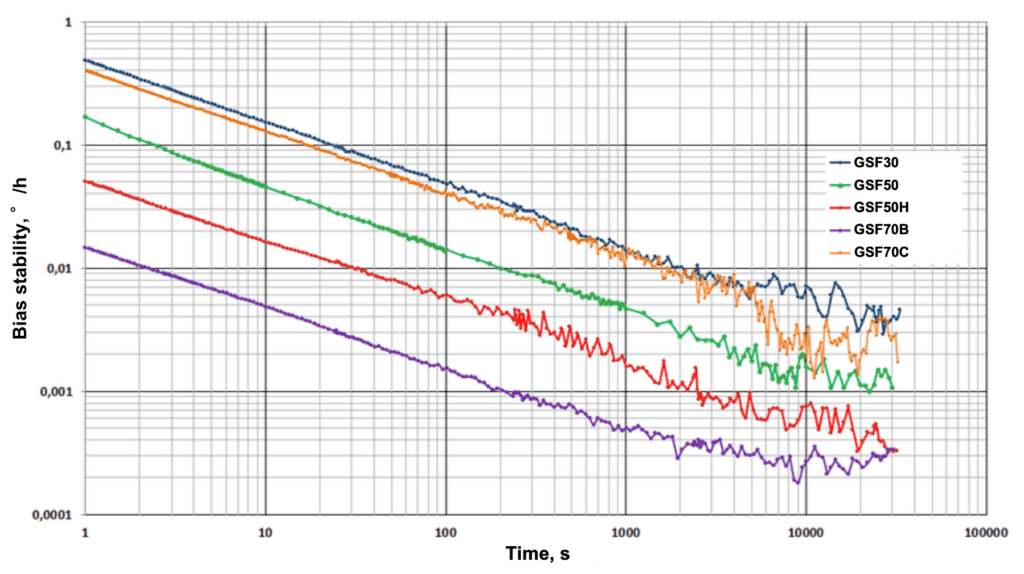

Especially bias stability, angle random walk, and scale factor non-linearity. These determine the accuracy class and directly impact pricing.

2. Optical Coil Design

The quality, symmetry, and length of the fiber coil significantly affect sensitivity and thermal stability.

3. Loop Architecture

Closed-loop FOGs offer better linearity, wider dynamic range, and higher signal fidelity. However, the feedback circuitry and control algorithms add cost compared to simpler open-loop systems.

4. Axis Configuration

More axes mean higher cost. Single-axis is simplest, dual adds integration effort, and three-axis requires full system calibration and compact design-making it the most expensive.

5. Reliability Qualification

Each device undergoes rigorous factory testing and certification. However, meeting additional military standards (e.g., MIL-STD-810G) increases production costs due to higher structural strength, enhanced thermal shock resistance, and extended stress testing.

6. System Interface & Housing

Special requirements for connectors, output formats (RS-422, CAN, Ethernet), or enhanced housing (e.g., waterproofing, pressure resistance, magnetic shielding) often require redesign and material changes, leading to added validation, prototyping, and testing-thus increasing overall cost.

7. Calibration and Testing

High-end FOGs undergo extensive multi-temperature and multi-axis calibration routines, which add both precision and cost.

While many variables contribute to the final price of a fiber optic gyroscope, I’ve consistently found that bias stability, coil design quality, axis configuration and environmental durability have the most significant impact. These three factors not only define a FOG’s real-world performance but also account for the majority of engineering complexity and production cost. Understanding their influence is key to making informed decisions. Next, I’ll take a closer look at these critical cost drivers.

How Does Bias Stability Influence FOG Pricing?

Bias stability measures how much a FOG drifts over time—crucial for maintaining long-term accuracy in inertial systems, especially without GNSS. Lower drift means higher stability and system reliability, which is vital for short-term inertial-only navigation after GNSS loss. It plays a key role in ensuring the effectiveness of tactical or strategic missions.

However, achieving such high stability requires:

- Ultra-stable laser sources

- Sophisticated thermal compensation

- Rigorous multi-axis calibration

These enhancements significantly increase design complexity and production cost. Tactical-grade FOGs with 0.2°/h bias stability are relatively affordable. In contrast, navigation-grade models offering <0.05°/h can cost 3–5× more due to tighter tolerances and rigorous testing.

In short, better bias stability means higher precision—and a significantly higher price tag.

How Does Angle Random Walk (ARW) Influence FOG Pricing?

ARW reflects the short-term noise in a FOG’s output. Lower ARW (e.g., <0.0002°/√h) means cleaner signals and better short-term accuracy—essential for fast-response systems like missile guidance or gimbals.

Achieving low ARW requires: high-quality fiber coils, low-noise photo detectors, advanced filtering algorithms

These enhancements require tighter tolerances and refined assembly, significantly increasing cost. FOG gyros with ultra-low ARW (<0.0002°/√h) can be 5 to 10 times more expensive than tactical-grade units (0.02°/√h), especially when paired with low bias stability.

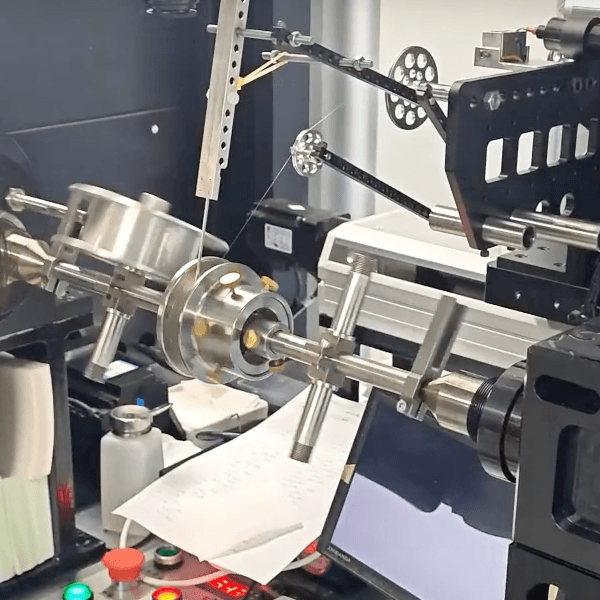

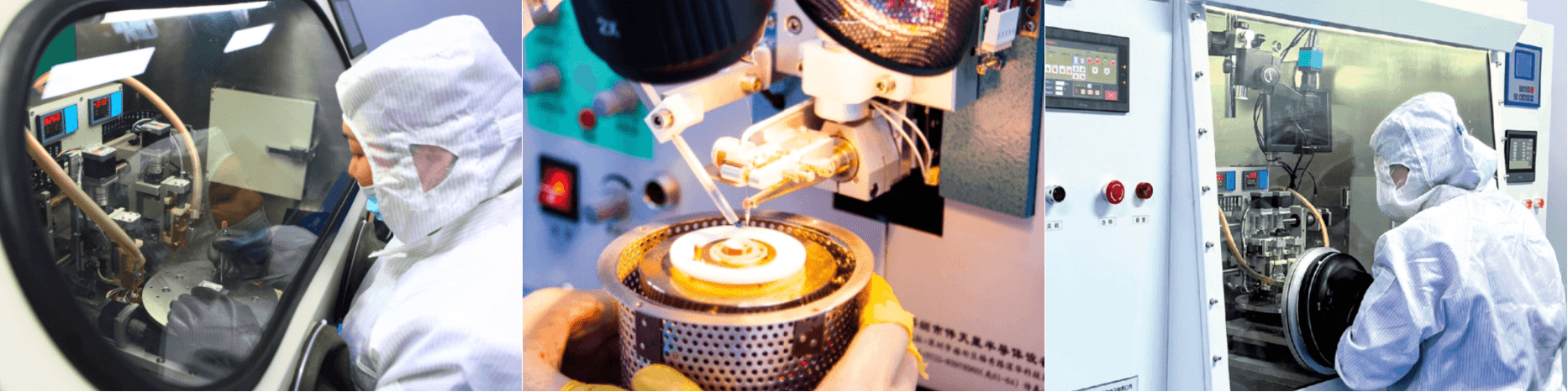

Why Does Optical Fiber Coil Design Significantly Impact FOG Cost?

The optical fiber coil is the core sensing element of a Fiber Optic Gyroscope (FOG), and its quality has a direct impact on the system’s accuracy, stability, and long-term reliability. The more precise and stable the coil, the higher the production cost.

Key factors such as:

Fiber length

Winding precision

Symmetry

directly influence the FOG’s sensitivity, bias stability, and scale factor linearity. To achieve tactical or navigation-grade performance, coils must be wound in cleanroom environments using temperature-controlled and vibration-isolated machinery.

Additionally, low-polarization and radiation-hardened fibers, specialty coil bobbins, and post-winding annealing processes further drive up material and labor costs. As a result, optical coil production remains one of the most technically demanding and cost-intensive processes in FOG manufacturing.

Do Harsh Environmental Requirements Affect the Cost of a FOG?

Deploying FOGs in harsh environments requires more than performance—it demands physical survivability. Meeting standards like MIL-STD-810 involves:

- Sealed and reinforced housings

- Vibration isolation structures

- Extended temperature range testing

Environmental hardening typically adds 20–40% to unit cost, depending on the required certification level. For example, the same FOG built for lab use may represent a baseline cost, while the MIL-STD-compliant version for defense platforms can cost 50–75% more due to additional requirements in materials, ruggedization, and testing.

What Are the Accuracy Grades of FOGs—And How Do They Impact Cost?

One of the first things I help clients clarify at GuideNav is what accuracy class they actually need. Many teams initially request the highest-spec unit available—only to find it’s overengineered for their application and budget. Understanding the differences between FOG accuracy grades is the key to balancing cost and performance.

Here’s a breakdown of the three main categories:

| Grade | Bias Stability (1σ, 10s) | Typical Use Cases | Price Range |

|---|---|---|---|

| Tactical-Grade | 0.1–0.2 °/h | UAVs, UGVs, industrial equipment | $3,000 – $8,000 |

| Navigation-Grade | 0.01–0.1 °/h | Marine navigation, survey systems, AGVs | $8,000 – $20,000 |

| Strategic-Grade | < 0.01 °/h | Missiles, aerospace systems, submarines | $20,000 – $100,000+ |

At GuideNav, we offer FOGs across all three grades—each tested and calibrated according to its intended application environment. Choosing the right grade ensures both mission reliability and cost efficiency.

Are There Low-Cost Alternatives to Traditional FOGs?

In cost-sensitive projects, alternative gyro technologies are often considered to replace traditional FOGs. While these options may appear attractive on paper, I’ve seen firsthand how their limitations surface quickly under demanding conditions.

| Technology | Typical Application | Limitations Compared to FOG |

|---|---|---|

| MEMS Gyroscopes | Consumer drones, robotics, entry-level IMUs | Inconsistent bias, poor long-term stability, sensitive to vibration |

| Ring Laser Gyroscopes (RLG) | Aerospace and missile systems | Comparable accuracy, but larger, heavier, higher cost |

| Dynamically Tuned Gyros (DTG) | Legacy military platforms, industrial machinery | Mechanical components wear over time, lower accuracy |

| Magnetometers / Digital Compasses | Low-cost heading reference | No inertial sensing, prone to magnetic interference |

| Optical Encoders | Industrial rotation tracking on fixed axes | Not inertial—cannot measure angular velocity or acceleration |

In my work with inertial systems, I’ve rarely seen these alternatives meet the requirements of high-precision or mission-critical environments. When drift control, temperature resilience, and motion stability truly matter, a well-built FOG remains the most reliable choice.

Does Customization of FOG Impact the Price?

FOG customization is often necessary when standard models can’t meet system-level integration or environmental requirements. However, these modifications typically add 20–50% to the base cost.

Common custom requests include:

- Non-standard housings or mounting

- Special output interfaces (CAN, Ethernet, etc.)

- Extended temperature or shock resistance

- Built-in sensor fusion or software adaptation

The more specific the requirements, the more engineering time, testing, and qualification are involved—making customization a significant cost driver in most programs.

How Can GuideNav Help?

At GuideNav, we specialize in delivering high-performance Fiber Optic Gyroscopes (FOGs) engineered for mission-critical applications across defense, aerospace, and industrial sectors. With decades of expertise in inertial technology, we provide precision, reliability, and integration flexibility at every level.

1. High-Performance FOGs for Demanding Environments

Our FOGs are designed to meet strict requirements for accuracy, bias stability, and durability. Whether for UAVs, ground vehicles, naval platforms, or missile guidance, we offer tactical, navigation, and strategic-grade FOGs tailored to the specific performance needed.

2. Tailored to Your Integration Needs

GuideNav supports mechanical, electrical, and software-level customization to ensure seamless system integration. From custom housing and connector options to protocol adaptation and embedded filtering, we work closely with your engineering team to match exact system demands.

3. Precision Without Compromise on Cost

We understand that budget constraints are real—especially in scaled deployments. GuideNav offers highly competitive pricing for FOGs without sacrificing technical integrity. Our in-house production and vertical integration help us deliver consistent quality at globally competitive rates.