Inertial Measurement Units (IMUs) are the silent workhorses of modern navigation. They sense every movement, rotation, and acceleration, feeding vital data to UAVs, ships, land vehicles, and aerospace systems. Yet, despite their critical role, IMUs are often misunderstood or misused. Small mistakes at the integration stage can snowball into massive operational failures—resulting in drift, instability, or even mission loss. The truth is, integrating IMUs is not a matter of simply “plug and play.” It requires precision, discipline, and foresight.

IMU integration errors can destroy navigation reliability. From misalignment and vibration to poor calibration and overreliance on sensor fusion, engineers often repeat the same mistakes. In this guide, we explore the 10 most common mistakes in IMU integration, explain their consequences, and provide expert solutions you can apply in your own projects.

Table of contents

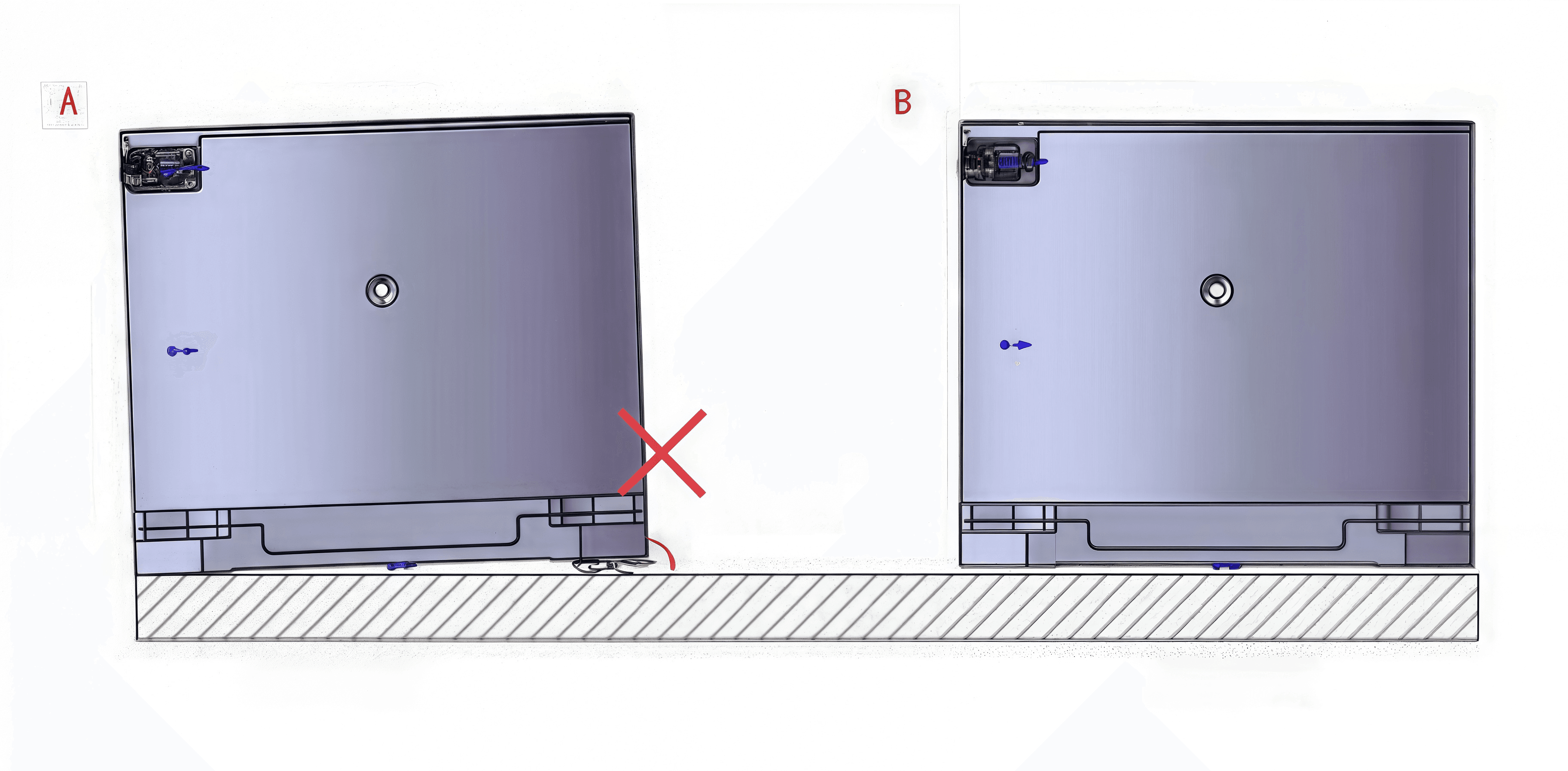

Misalignment During Installation

Mistake:

Engineers sometimes mount IMUs “close enough” to the platform’s reference frame without precise alignment. A few degrees of error may seem minor, but in navigation, these offsets grow into massive errors.

Impact:

Misaligned axes cause systematic bias in attitude and velocity estimates. Over long missions, this leads to increasing drift, especially in GPS-denied operations where the IMU is the only truth source. A UAV may slowly tilt off course, or a robotic vehicle may misjudge its heading.

Fix:

Always define reference axes in CAD, and use precision tooling such as laser alignment jigs during installation. After mounting, perform an alignment calibration to measure and compensate for small offsets.

💡Pro Tip: Never trust mechanical tolerances alone—post-integration calibration is your safety net.

Ignoring Vibration Isolation

Mistake:

Mounting an IMU directly onto vibrating structures like propeller arms, engines, or vehicle chassis, assuming the sensor’s internal filters will compensate.

Impact:

Vibration contaminates accelerometer signals and creates false angular rates in gyroscopes. The result is noisy outputs, unstable navigation filters, and visible jitter in stabilization systems. In aircraft or gimbals, vibration can ruin pointing accuracy.

Fix:

Use vibration isolators tuned to your platform’s dominant frequencies. Combine hardware damping with digital filtering to mitigate residual effects. Validate performance under real mission loads, not just lab benches.

💡Pro Tip: Always perform vibration spectrum analysis of your platform before finalizing isolation design.

Overlooking Thermal Management

Mistake:

Assuming that the IMU’s built-in temperature compensation solves all thermal issues.

Impact:

Real missions involve rapid heating from electronics, engine exhaust, or cold-soak conditions. These cause bias instability, scale factor drift, and degraded accuracy. In space, thermal cycling can be catastrophic if not accounted for.

Fix:

Design thermal control at system level. Options include insulating housings, adding heat spreaders, or even controlled heaters. Monitor onboard temperature sensors to track stability across the mission profile.

💡Pro Tip: Test IMUs under realistic thermal cycles, not just static temperature points.

Choosing the Wrong Performance Grade

Mistake:

Selecting an IMU based purely on cost, size, or availability, without considering mission duration or precision requirements.

Impact:

Consumer MEMS may look acceptable in short tests, but will drift uncontrollably in hours-long or GPS-denied scenarios. Tactical MEMS or FOG IMUs are required for serious missions, but teams often skip them to cut budget—leading to costly redesigns later.

Fix:

Match IMU performance (bias instability, Random Walk, bandwidth) to mission needs. Use consumer MEMS for hobby drones, tactical MEMS for UAVs and defense vehicles, and FOGs for maritime or aerospace operations.

| IMU Type | Common Misuse | Correct Application |

|---|---|---|

| Consumer MEMS | Chosen for cost | Short, non-critical robotics |

| Tactical MEMS | Overlooked for price | UAVs, UGVs, defense platforms |

| FOG IMU | Seen as overkill | Maritime, aerospace, GPS-denied operations |

💡Pro Tip: Always evaluate lifecycle cost of mission failure versus upfront sensor cost.

Poor Calibration Strategy

Mistake:

Relying solely on the manufacturer’s calibration, assuming it is universally valid.

Impact:

Mechanical tolerances, mounting errors, and connector stresses create system-specific biases. Without secondary calibration, these errors degrade navigation performance and fusion results.

Fix:

Perform system-level calibration, such as six-position tests or rate table characterization. Update calibration tables in firmware and repeat periodically for consistency.

💡Pro Tip: Treat calibration as a recurring maintenance step, not a one-time factory process.

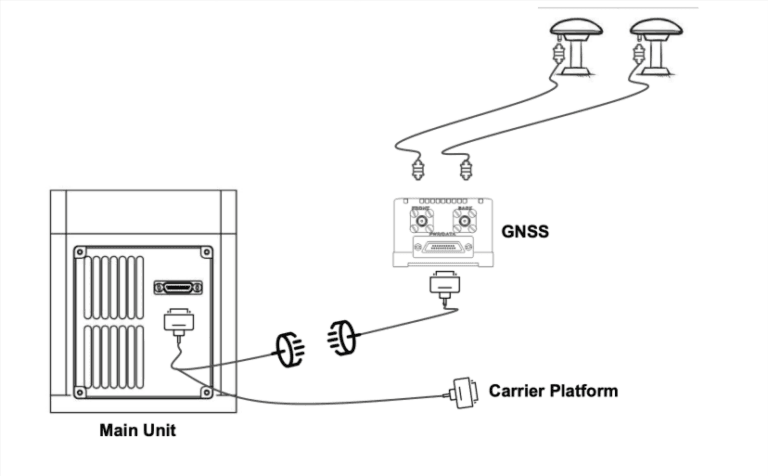

Inadequate Interface & Data Handling

Mistake:

Misconfigured sample rates, ignoring latency, or failing to synchronize data with other sensors.

Impact:

Even high-quality IMUs become unreliable if their data is delayed or misaligned. Fusion with GNSS, LiDAR, or vision fails when timestamps don’t match.

Fix:

Design robust data pipelines. Use PPS or hardware time stamps to keep everything synchronized. Validate end-to-end latency from sensor to processor.

💡Pro Tip: Think of time synchronization as part of sensor quality—not an afterthought.

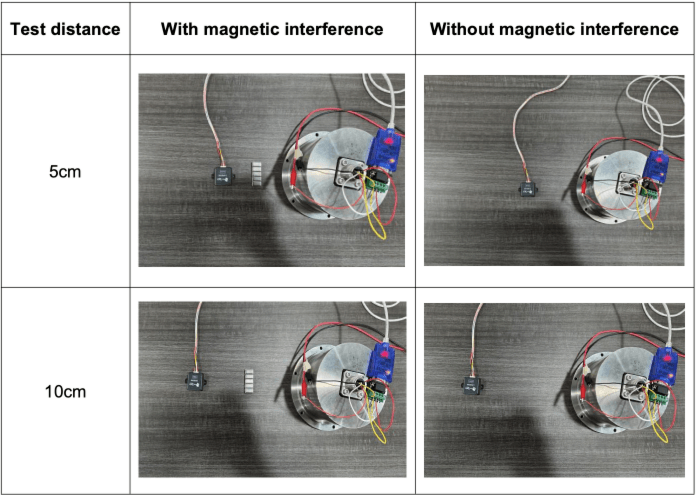

Ignoring Magnetic & EMI Interference

Mistake:

Installing IMUs close to motors, high-current cables, or RF antennas.

Impact:

Magnetic fields distort accelerometer and gyro signals. EMI noise couples into sensor electronics, causing spurious outputs. This is especially common in UAV gimbals, where compact designs push sensors dangerously close to motors.

Fix:

Place IMUs away from EMI sources. Use shielded enclosures, twisted-pair cabling, and grounding practices. Test under full electrical load to reveal hidden interference.

💡Pro Tip: A clean mechanical design can solve EMI problems more effectively than complex filtering.

Not Considering Long-Term Drift

Mistake:

Validating IMUs with short-duration tests, ignoring drift over hours or days.

Impact:

Bias instability accumulates, causing kilometers of position error. Systems that rely on IMUs alone (submarines, spacecraft, GPS-jammed UAVs) become unusable.

Fix:

Run endurance tests that simulate mission durations. Choose tactical or FOG IMUs for long-term navigation stability.

💡Pro Tip: Always evaluate drift across 100+ hours, not just 10 minutes in the lab.

Overreliance on Sensor Fusion

Mistake:

Assuming Kalman filters or AI-based fusion can fix weak IMUs.

Impact:

Poor sensor inputs simply pollute the filter. Instead of improving accuracy, fusion multiplies errors—“garbage in, garbage out.”

Fix:

Start with reliable IMU data. Fusion should enhance performance, not rescue bad sensors. Use redundancy where possible to verify signals.

💡Pro Tip: A good IMU reduces filter complexity and increases robustness dramatically.

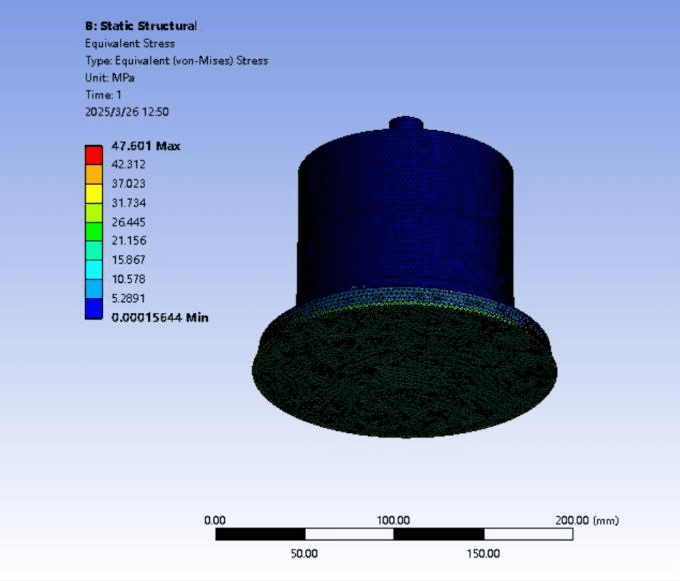

Underestimating Environmental Qualification

Mistake:

Testing IMUs only in lab conditions and assuming field results will be the same.

Impact:

Humidity, dust, shock, and extreme weather exceed commercial specs. Without proper qualification, IMUs fail in critical missions.

Fix:

Select IMUs tested under MIL-STD-810G, DO-160, or equivalent. Request test data, not just datasheet claims.

💡Pro Tip: Ask vendors for qualification reports—real data beats marketing promises.

Conclusion

IMU integration is both an art and a science. The most advanced algorithms or control systems cannot compensate for poor installation, bad calibration, or inadequate testing. By avoiding the 10 mistakes described here, engineers can unlock the true potential of IMUs and build systems that survive—and thrive—in the field.

At GuideNav, we provide a wide range of IMUs composed of high-performance MEMS / Fiber Optic / mini Fiber Optic gyroscopes and MEMS / Quartz accelerometers, all qualified under rigorous environmental standards. Our products are designed for UAVs, maritime systems, defense vehicles, and aerospace platforms where failure is not an option. If you need a mission-ready IMU, our experts are ready to support your integration journey.